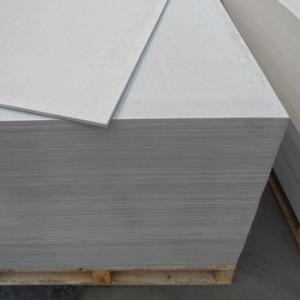

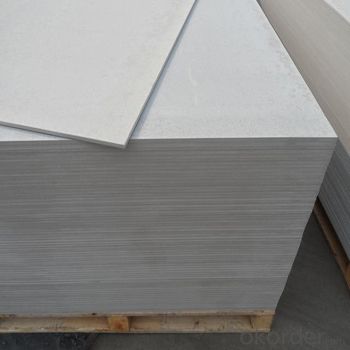

Non-asbestos Fireproof 12 mm Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non-asbestos Fireproof 12 mm Fiber Cement Board

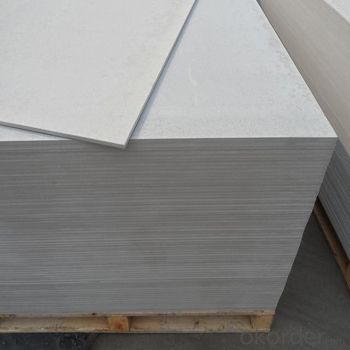

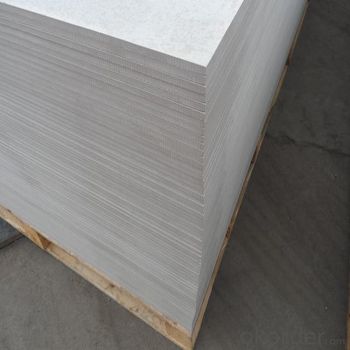

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Non-asbestos Fireproof 12 mm Fiber Cement Board

Sound and Weather Resistant:

Karmeen fiber cement boards deliver optimal sound and weather insulation. Noise as well as changing weather conditions such as freeze / thaw, heat and water pose no threat to fiber cement board. The boards retain their shape at all times.

Low Maintenance:

The ability of the boards to resist mold and algae attacks is equally impressive. The result is a long-lived façade that saves you time and effort on inconvenient and costly repairs and repaints.

Non-combustible:

The boards are non-combustible, which is your guarantee for a safe building.

Easy Handling:

Karmeen fiber cement boards are flexible and easy to handle. They can be delivered cut to size, ready for installation. All this makes for lower construction costs, shorter construction times, and lower installed costs.

Board Edge:

Packaging Details:

Fumigation wooden pallets+PE cover + corner protector

Non-asbestos Fireproof 12 mm Fiber Cement Board

- Q: This building was previously a school building, with cement block walls..I need to know if I need backer board, or do I just need to fill in the low spots to make the wall flat and level? Also, what kind of thinset do I need for clear glass mosaics?

- You don t need a backer board.. As long as the block is solid and no cracks ( they need to be treated specially) you can go right over the block with a few precautions. The block needs to be clean and smooth. No mortar from the joints and stick out. If the walls are unpainted ( and clean) you can go over them with WHITE and white only thin set.There is no such thing as colored or tinted thin set.And glass tiles call for a strong latex modified thin set If the walls are painted ( and clean) you can use a mastic or the special thin set. Fill in the mortar joints with the adhesive you use. Mastic cannot be used if this is a wet area or going to be a wet area. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Do you have to tape and fill seams on cement board when applying ceramic tile over it like when doing drywall?

- Yes, you'll use fiberglass mesh tape to tape the seams and a coating of thin-set mortar

- Q: after installing my bathtub do i use 1/4 in. or 1/2 in. cement board for surrounding before ceramic tiling?

- 1/2 will hold up better to the weight of the tile and someone banging into it.

- Q: My bathroom has a section where there is cement board. Over the cement board is a layer of plaster. Tiles were glued to the plaster. However, the plaster came off of most of the cement board over time. Of course, the tiles have fallen off too. So now I have bare cement board partially covered by plaster.I'd like to remove the remaining plaster from the cement board and then retile directly over the cement board.How to best remove the remaining plaster? Is chipping away at it the only method?

- it might be easier to cut the section out and start fresh

- Q: can plywood be used instead of cement backer- board for tile?

- Im not for certain but i don't think it can be used instead of cement backer board. Plywood is very preamble and the grout may soak through? I would call a Lowe's or Home Depot and ask for the flooring dept. or lumber and ask them.

- Q: We have an older house (1957) that has 1 thick beams as a substrate floor. Currently, there is 1/2 plywood on top of the substrate floor. We are going to rip this up so that we can apply mortar to the substrate for leveling purposes. We would put the porcelain tile directly on top of the cement board.The guy at Home Depot (a former contractor) said we can just use 1/2 cement board directly on top of the substrate floor without a layer of plywood underneath. The substrate is old, but sturdy real-wood diagonal beams that lay on top of the joists. He said they are plenty strong and we don't really need to add a plywood subfloor if we use 1/2 thick cement board.What do you think? Do you think we could get away will laying down cement board on top of the substrate floor without plywood for added strength?Thanks!

- Cement Board Subfloor

- Q: How about wood wire cement board? Is it environmentally friendly building materials?

- The cement board is very good. It is environmentally friendly green building materials, from the cement as a cross-linking agent, wood as a fiber reinforced material, adding part of the additives made of the plate, mainly by the crushed wood and Portland cement gluing processing, color cleaning, double Smooth and smooth surface. The product combines the strength of wood, ease of processing and cement durable characteristics. Wood fiber cement board in the 40's began to be widely used in Europe, has now become a wide range of international application of building materials. It is versatile, excellent performance, with corrosion resistance, heat resistance, resistance to corrosion, easy processing, and cement, lime, gypsum with good, green and other advantages. Now, the Netherlands, Finland, Germany, Austria, Russia and other countries have formed a number of such special plate manufacturing company, as well as professional equipment manufacturers, compared to China's less such production lines, wood The development of the domestic space is relatively large, to be the depth of development and utilization.

- Q: Can someone tell me if they know or what they would think is stronger, six cement blocks stacked high or a board that is 6 feet long and 6 by 6?

- are the cement blocks stacked without mortar? are the cement blocks loaded in bending or compression? is the board loaded in bending or compression? What is the criterion of failure? cracking or breaking? Not a fair comparison with out some explanation.

- Q: What is the difference between building curtain wall and architectural facade decoration?

- Building curtain wall is the building does not load the external wall of the Wai, usually by the panel (glass, aluminum, slate, ceramic plate, etc.) and the back of the support structure (aluminum beam column, steel structure, glass ribs, etc.). Building wall with the definition of the law, set up A ~ B for a wall, if A ~ B wall line can be cut about the relevant structure of the wall, and vice versa for the external walls. From the architectural point of view, the enclosure of buildings, so that the formation of indoor and outdoor demarcation components known as the external walls. Its functions are: take a certain load, shelter wind and rain, thermal insulation, to prevent noise, fire safety.

- Q: The original floor pull up the steel in the layer of cement mortar, safe?

- If you are afraid of a problem, do the bottom of the paste carbon fiber, is a better way

Send your message to us

Non-asbestos Fireproof 12 mm Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords