Non Asbesto Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

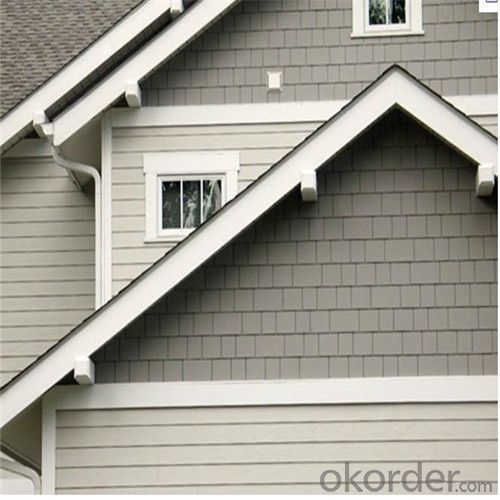

Applications

Exterior side boards, indoor partition walls, sound-proof ceiling, decoration boards, complex walls, outdoor billboards, division boards and floor boards

- Q: Cement board spray really stone paint

- In fact, you can do the first door with wood or asbestos fastener to do the foundation ah, and finally do paint, the same effect.

- Q: I'm putting in a new tub surround this weekend (gutting the bathroom wall and starting from scratch). After I put cement board on the studs and install the tub surround, there will be a space about foot high between the surround and the ceiling. The cement board will be exposed. Can I paint the cement board so it matches the colors of the bathroom? Do I need to buy special paint or something? Obviously, I've never done this sort of thing before and I appreciate any advice I can get.

- You may want to run the concrete backer only about 3' up that will cover the real wet part of the tub surround then just use the green sheet rock on the top. Tape and float it put the surround up then texture and paint. Use semi gloss paint all over your restroom area with a added mildew inhibitor even if the paint is mildew resistant. Just tell them you don't care you want to add it anyway.

- Q: why does concrete block crumble but driveways and sidewalk do not?I don't have a driveway so basically i want to build a flat portable surface, made out of cement that my jack-stand (for my car) can stand on so the jack-stand wont have to be put directly in the grass.I would need it for the time that i need to take the tires off. any suggestion?

- a piece of a plank or any thick wood

- Q: I used a razor but it killed the blade in about two seconds. Is there a special saw for this stuff that won't make a huge mess?

- There is no easy way to cut cement board. It's just messy, I just bite the bullet and cut it with a masonary blade in a skill saw (I use my near death saws for that kind of work) that concrete dust is bad (were a mask). If your duing long rips, have a helper with a vaccum or compressor, suck or blow a clear line of site. That suck or blow comment will raise eyebrows. just leave it alone.

- Q: What is the difference between cement board decoration and gypsum board?

- Cement pressure plate is based on natural fibers and cement as raw material, by the pulp, forming, cutting, pressing

- Q: Bent cement board while installing onto floor...will it be ok?

- bent or cracked ? best that you get some cement and smooth it down or screw it to the floor if trhis is in prep for a tile floor then it will be OK .....

- Q: i'm replacing the tiles in my tub area and i'm changing the existing wall to cement board. how do i join it with the rest of the bathroom wall that's texture?

- Screws in to the studs.

- Q: How do I remove dried cement from door & running board?

- If it hasn't hardened for very long, Like weeks, try water and a stiff nylon brush. If needed take a plastic scraper and try to pop it off being careful not to gouge the paint Usually if you get the cement wet it will loosen from paint. I have removed cement from aluminum siding this way. Good luck

- Q: I use the card light steel keel to do the wall and ceiling, do not want to be fooled, seeking the experience of the people advise

- Card keel for aluminum ceilings, aluminum buckle plate, aluminum buckle, aluminum hanging plate with different products with the card keel or some difference. If you are not using these materials, it is not a card keel: The main dragon with U50, U60, U38 corresponding to the vice bone C50, C60, C38, the general 38 has been able to meet the use of small area ceiling, the main material gypsum board or calcium silicate board, fiber cement board, size 2440 * 1220, thickness 6-8MM;

- Q: How much is the square of the cement board

- With the development of China's modernization drive, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old building renovation, interior decoration, roof and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on. I hope that my reply is helpful.

Send your message to us

Non Asbesto Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords