UV Coating Wood Grain Decorative Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

1. High strength and light weight

2. Fireproof and waterproof

3. 100% free of asbestos

4. Energy saving.

2,Main Features of the (Cement Boards)

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Thickness: 3.5-30mm

Standard size: 1220*2440mm or 1200*2400mm

Note: other specification is available

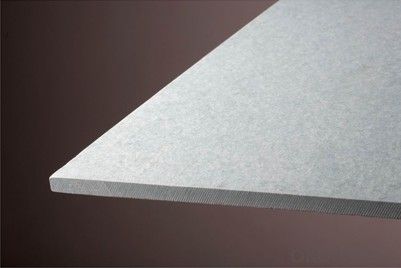

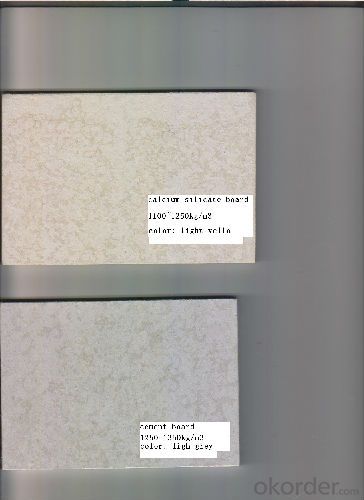

3,(Cement Boards) Images

4,(Cement Boards) Specification

Index | Moderate compressed | ||

Density(g/cm3) | 1.44 | ||

Water absorption (%) | 28 | ||

Wet expansion (%) | 0.17 | ||

Water penetration | No water drop on the board surface after 24hours | ||

Modulus of Rupture | Air dried condition | 14 | |

Saturated condition | 10 | ||

Frost resistant | No delamination and crack after 25cycles under freezing and thawing | ||

Index | High density | ||

Density(g/cm3) | 1.64 | ||

Water absorption (%) | 17.8 | ||

Wet expansion (%) | 0.15 | ||

Water penetration | Back side without water drop after 24 hours | ||

Modulus of Rupture | Air dried condition | 20.1 | |

Saturated condition | 15.0 | ||

Frost resistant | No layers and no cracks after 25 cycles under freezing and thawing | ||

Index | Middle density | ||

Incombustibility | Incombustible Class A1 | ||

Water penetration | Back side without water drop after 24 hrs | ||

Modulus of rupture | Air dried condition | 15 | |

Saturated condition | 12 | ||

5,FAQ of (Cement Boards)

1. Interior and exterior wall; Furred ceiling

2. Insulation materials, floor; Road barrier

3. Sound-adsorbing wall & suspended ceiling

- Q: Can cutting the steel cutting machine cut the cement board?

- Can not cut the reinforced toothless saws are grinding wheel pieces, while cutting the concrete slabs to use the toothless alloy steel saw blade.

- Q: Directly on the cement board to brush the glass can you!

- Yes, but before the brush to re-clean the cement, can not have dust, or paint easy to fade.

- Q: I am in the Chicago area and it rained a few days ago.... I am also using molds and wood 4x4's

- You can pour the cement one day and let it dry over night --You should be able to nail the boards onto it the next day. Wait for a day with (no rain) to pour cement. We just built a fence and poured the cement and it set up real well by the next day--but it was not raining. Good Luck on your fence

- Q: What is the difference between a cement pressure plate and a cement board?

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Widely used in civil and industrial buildings. Can be used for building floor, interior wall panels, exterior panels, ceiling panels, curtain wall panels, composite wall panels, insulation materials, roofing and other parts.

- Q: We recently bought a house with a corner tub in the master bathroom. There was a partially covered pipe for a shower head but the walls are not waterproof. Since the plumbing is there for a shower we would like to waterproof the walls and put in a shower head. Is there a chance the builder put up cement board but skipped tiling? Is there a way to tell without ripping the walls down? Also I'm wondering if we need to tear down the existing drywall and put up cement board or if we can just use a type of acrylic shower wall and caulk it really well. Any advice would be appreciated.

- tricky aspect seek onto yahoo or google that might help

- Q: What are the brands of cement fiberboard

- At present, well-known brands are Eide board, the new element board, the East board, the German plate, easy and board, Zhejiang Greenbok Board Co., Ltd. 100 wood fiber cement board, sea dragon board, Hadi board, etc., the name of these plates are corresponding to the corresponding company name or brand.

- Q: Toilet decoration with light steel keel gypsum board vertical wall. What can be done with a hanging brick?

- To hang brick, you can use light steel keel partition, but to use cement board cover, can not use gypsum board

- Q: The difference between cement fiberboard and cement pressure plate

- Cement fiberboard and cement pressure plate is a product of two names, there is no difference. Plate of cementitious materials are cement, reinforcing materials are fiber (asbestos fiber and / or cellulose fiber).

- Q: am Laying Floor Tile and was Wondering if the Mesh Tape for Cement Board is the Same as you use for Drywall?

- yes it is. Use thinset over tape

- Q: Just put cement type 1 portland,over hardie board about 3/8 of an in. how long do i have to wait to stain it?

- i would give it a week, it should set pretty quick...

Send your message to us

UV Coating Wood Grain Decorative Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords