Fireproof Fiber Cement Board Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Fireproof fiber Cement Board

The compressed machine is 14000 tons, So we can produce density over 1600kg/m3. 100% Non asbestos

Product Advantages:

Fireproof fiber Cement Board

Headerboard high density fiber cement board is 100% free of asbestos. The compressed machine is14000tons. So we can produce density over 1600kg/m3.Thickness from 4mm-30mm, Standsize is 1220*2440, size can be customized according to your requirement.

The production line was introduced from Germany. There are total two production lines now. Production capacity is 20 million square meters per year. We can send you boards earlier than other supplier.

Main Product Features:

Product Name | Fireproof fiber Cement Board |

Raw Materials | Cellulose Fiber, Quartz Sand, Portland Cement |

Standard Size | 1220X2440MM / 1200X2400MM |

Maxium Width | 1250MM |

Maximum Length | 4880MM |

Thickness | 4-30MM |

Density | 1.5-1.7G/CM3; 1.2-1.4G/CM3 / 1.4-1.5G/CM3 |

Wet Expansion | ≤0.23% |

Water Absorption | ≤25% |

Incombustibility | Incombustible Class A1 |

Water Penetration | Back side without water drop after 24 hours |

Flexural Strength | Air dried condition: ≥18; Saturated Condition: ≥14 |

Radioactivity | Decorative materials Class A |

Frost Resistance | No layers and no cracks after 25 cycles under freezing and thawing |

Asbestos | 100% free of asbestos |

Certification | ISO, CE, SGS |

Packaging | Standard wooden pallet |

Trade Terms | FOB, CNF, CIF |

Payment Terms | T/T, Irrevocable L/C at sight |

Delivery Time | Within 15 days if stock not available |

Main Characteristic | Environmental friendly materials |

Excellent Strength and toughness | |

Waterproofing and fireproofing | |

Antisepsis and moth-proofing | |

Good acoustic insulation and weather resistance | |

Good thermal and heat insulation | |

Durability and long lifetime | |

Application | Exterior decoration panel |

Intergrative facade panel for exterior wall thermal insulation | |

Interior wall decoration panel | |

Flooring for loft interlayer, container house, light steel villa | |

For subway, tunnel,baseboard, outdoor furniture | |

Roofing sheet | |

Thinner lining board for stone |

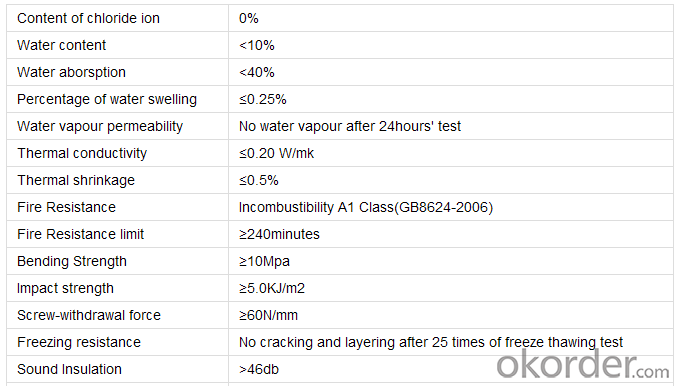

Product Specifications:

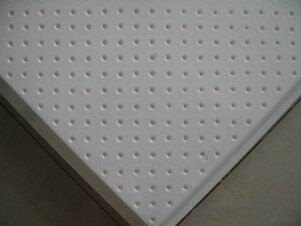

Images:

- Q: Cement board spray really stone paint

- It is recommended to use the steel structure to do the foundation, first by 4.5 meters high 5 meters wide welded into the door type, and then use the GRC production of cement board (which vertical laying 6 PCT or 8 PCT steel, solder joints) welded to the steel structure, the surface Treatment is waterproof putty and spray really stone paint!

- Q: What do I do

- it may be broke

- Q: Glass fiber reinforced cement (GRC) board is what

- GRC is glass fiber reinforced cement products. He is composed of anti-alkali glass fiber and low alkalinity cement composed of a new type of hydraulic composite material, its main features are high strength, crack resistance, fire resistance, good toughness, not afraid of cold, easy to shape, can be made into thin, , The shape of a variety of complex building components and products, in the civil construction of agriculture, animal husbandry and fishery and environmental art and other fields have a wide range of uses. GRC Finished material is made of this composite material such as: GRC European-style components, high-strength GRC curtain wall panels, etc.

- Q: I have a small bathroom approximately 4'x8' and I laid down and screwed in cement backer board. However, in my attention to detail I neglected to put down thin-set mortar underneath prior to screwing and taping down the board. I tried to pull the cement board up but I cant get under the tape that I mortared down to get to the screws. Am I in trouble here or can I go ahead and skip that and continue to tile? Please help...

- Make sure your screws hit framing members and not just plywood. Use an exterior grade deck screw, penetrate the framing member a minimum of 3/4 @ 5 o/c.

- Q: Looking to connect a piece of plywood between two boards to hang a banner

- I am okay with the 5 gallons of concrete, that will weigh close to 100 lbs per bucket. I would use 1.5 - 2 inch pvc pipe, not 2x4's. That will give you better flex. For the banner, it is up so high that the wind loading and leverage will be a problem if you tie all four corners. So just connect the two poles with a rope at the top and hang the sign from the rope. This way in a wind, the bottom will just blow free. If you must tie the banner at 4 corners, you need a flatter container of concrete. An old tire, filled with concrete, will work for this purpose. Put a piece of plywood across the tire so it will hold the concrete. That's what we used for tether ball.

- Q: Bathroom renovation. New shower installation. Question is when installing the cement boards along the shower w?

- I agree.. Whats the question?.. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Our (rented) townhouse has a very bleak cement block basement. Right now the blocks are painted white and cream (and not in a pretty pattern) and the floor is painted dark gray. We want to use the basement as a fitness room and a crafting area for scrapbooking. The lighting is also terrible. What are some ways we can brighten up the space and make it more hospitable without doing any permanent construction (remember we are renting) or spending a lot of money?

- A cheap way to decorate for a workout room and scrap book room is to buy some stand up mirrors and place them up against the walls. Any lighting that you have will magnify and you will be able to see your physical development while working out, and you can take them with you when you leave. Good Luck

- Q: how do i install stone veneer over cement board?

- Use thin set and stick them right to the c-board. If they are bigger pieces you should screw wire mesh to the cement board for a good bond then tuck point joints After it sets or use a bakers bag.

- Q: Which is better adhesive or mourter for applying ceramic tile on cement board floor?

- The first and most common is Polymer Modified thinset. It's the least expensive, and the most common for a floor. MAKE SURE YOU GET POLYMER MODIFIED. It will say on the bag. The next is a premixed tile mastic. This is usually used for walls since it has more initial grab and helps keep the tiles from vertically sliding. There is nothing wrong with using premixed mastic as long as the tile is indoors. It will cost more however, and will also take longer to dry. If your doing a small area it might be easier since you don't have to mix it.

Send your message to us

Fireproof Fiber Cement Board Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords