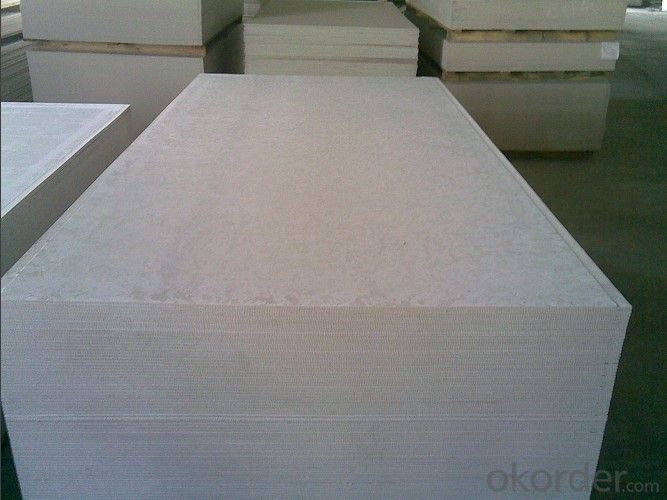

Fiber Cement Boards Fiber Cement Board For Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

Fiber cement board can be used in exterior wall cladding and facade of various high-class and high rise civil buildings especially in the modern luxurious buildings. Outstanding sound insulation of the system composed with Bysink external wall board can be used in indoor partition and suspended ceiling for the high demand in private request as sound insulation and such as five star hotel, bedroom, and public entertainment.

Also it can be used as the interior partition in the shops, hotels, schools, entertainment places and hospitals.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

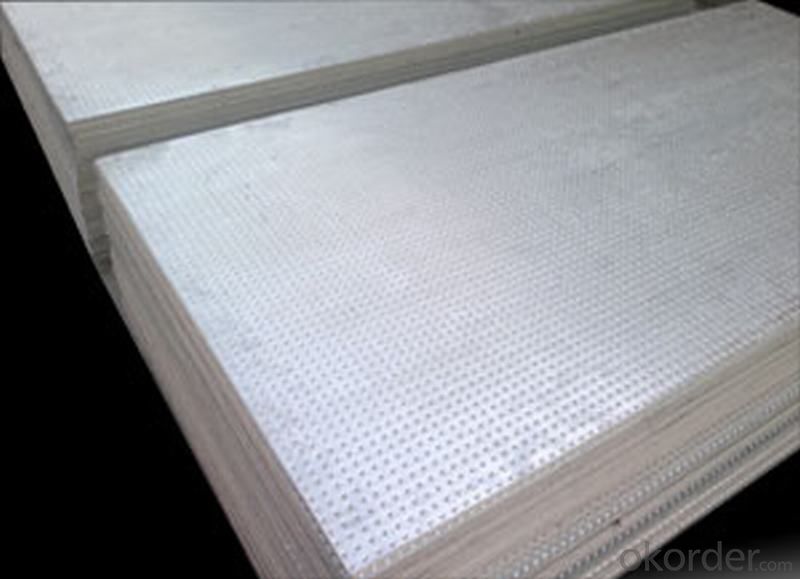

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q:why does concrete block crumble but driveways and sidewalk do not?I don't have a driveway so basically i want to build a flat portable surface, made out of cement that my jack-stand (for my car) can stand on so the jack-stand wont have to be put directly in the grass.I would need it for the time that i need to take the tires off. any suggestion?

- use some bricks to support the car and the use of your jack and stands on bricks get a refrigerator box to slide on while working on the car ... much cheaper and less mess than concrete makings ...

- Q:I would like to make my exterior walls more resistant against water and termites, so I would like to put cement boards instead of plywood boards before installing new vinyl siding. It costs a bit more but I think it would be worth it.

- It would cost double the amount of plywood .The nails won t hold good in just the cement board.When nailing into the cement board you may pound through the cement board if there is no wood support under it, but other than that there is no reason you couldn t. In other words I wouldn t suggest it. GL

- Q:how do i install stone veneer over cement board?

- Use thin set and stick them right to the c-board. If they are bigger pieces you should screw wire mesh to the cement board for a good bond then tuck point joints After it sets or use a bakers bag.

- Q:can cement board be cut into narrow 6 strips and used to make wall studs?

- No, it provides nothing to nail into, which is the purpose of studs and it has very limited strength if in a load bearing wall. And if you mean cutting a whole bunch of pieces and stacking them to get a 6 wide by 3.5 deep (like a 2x4) it would be a huge waste of materials and cutting blades. If you are looking for fireproof, consider metal studs. If you are looking for sound proofing, use offset stud techniques.

- Q:Cement fiber board now market price?

- This is how much you want to ask the manufacturers, are a lot of change

- Q:What is the difference between cement calcium silicate board and cement fiberboard

- Silicon calcium board mainly composed of gypsum, from the siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, through the pulp, into blank, steaming, surface sanding process And made of light plate.

- Q:Can cutting the steel cutting machine cut the cement board?

- Cutting machine: With the development of modern mechanical processing industry, the quality of cutting, precision requirements continue to improve, to improve production efficiency and reduce production costs, with high intelligent automatic cutting function requirements are also improved. The development of CNC cutting machine must meet the requirements of the development of modern mechanical processing industry. Cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water cutting and so on. Laser cutting machine for the fastest efficiency, the highest cutting accuracy, cutting thickness is generally small. Plasma cutting machine cutting speed is also very fast, cutting a certain degree of slope. Flame cutting machine for the thickness of the carbon steel material.

- Q:I'm preparing to replace the tiles in my foyer. It's a townhouse, about 20 years old with no basement. I don't know much in the way of construction, but since it's on ground level I think there might just be a cement slab underneath the existing tile. Can I install the tiles directly over the cement slab after removing the old tile or do I need a backer board? And if I do, how do I account for the height difference? Thanks in advance!

- Yes you can install Directly on the concrete Floor you don't need any Cement Backer Board

- Q:Aluminum-plastic board Aite board lighting board are used in what place

- Aluminum plate and the purpose of the board should be roughly the same, such as the inner wall and the wall and cut off! The But the Etter board is the fiber cement board can do LOFT mezzanine.

- Q:over the bath tub is durock cement board enough by itself,or it has to be something else under durock...?

- You need to attach the durock to the studs behind it. I am assuming you will then cover the durock with tile and grout and caulk it, that will keep the moisture out of the walls. Nothing has to cover the stud walls behind unless this is to be a steam shower (much more prep will be needed)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Boards Fiber Cement Board For Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords