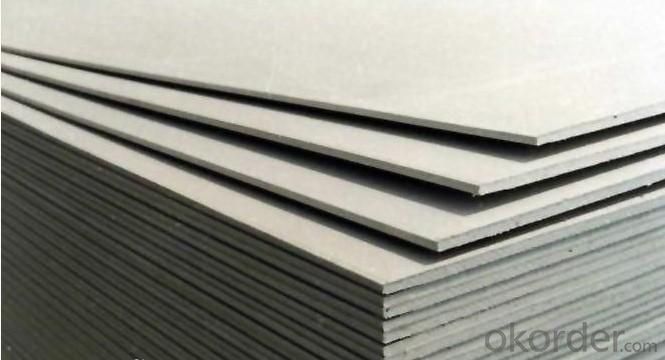

Fiber Cement Board 6mm Fiber Cement Board 6mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

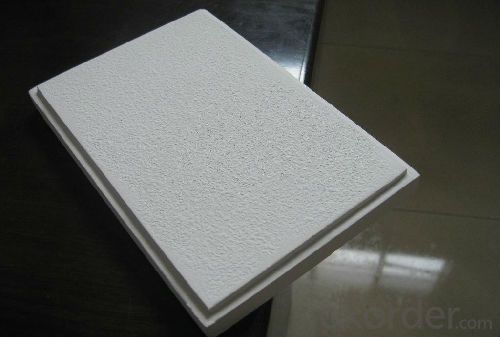

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

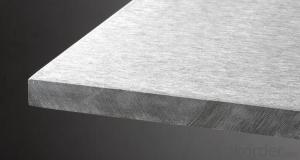

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: Will the reinforced concrete cement board be soaked in water for a long time?

- Reinforced concrete cement board pouring density is good, long-term bubble in the water will not rust cracking.

- Q: I've installed a fair amount of this stuff behind tub-surrounds & showers. I generally use a jig saw with a carbide blade, which promptly goes dull. Any experienced tile workers out there find a better way?

- If you can handle a little dust, they make a cement board blade for a 7 circular saw. It has about 24 big teeth on it and it slices right though. It will give you a nice clean edge. But there is the dust factor so I always set up outside and use a dust mask. I've used the blade for about 3 years and it is still sharp.

- Q: Will Titebond II (weatherproof) work? I have a 1928 home and am trying to duplicate one of the original exterior window sills to go on a new window. I need to glue a couple of 5/4 pieces together to get the right thickness and I want it to last. The originals have redwood but it's old growth I believe and more stable than what I can find now in redwood or DF. Correct me if I'm wrong there. Plus I have only two attaching points to work with on either side of the window so I chose the fiber cement product for it's stability. Nothing on James Hardie's site says what can be used to glue it with though.ThanksThanksChris

- I would use gorilla glue which is 100 percent waterproof. or you could use polyurethane caulk which is very tough.

- Q: Attic with a channel steel structure, covered with aluminum instead of wood multilayer? Is it feasible?

- Home decoration to do the attic, channel structure, decoration master said just just to shop a layer of 1.8cm wooden multilayer board and then shop the floor, multi-layer board formaldehyde exceeded, want to replace the wood multilayer 5mm aluminum.

- Q: I am in the Chicago area and it rained a few days ago.... I am also using molds and wood 4x4's

- You can pour the cement one day and let it dry over night --You should be able to nail the boards onto it the next day. Wait for a day with (no rain) to pour cement. We just built a fence and poured the cement and it set up real well by the next day--but it was not raining. Good Luck on your fence

- Q: I currently have aluminum siding on my house, I want to replace it with stucco. I need to do a full tear off because behind the siding is compressed fiberboard. I will need to apply a backboard to stucco over, so the question is, should I apply cement backer board, hardiboard or plywood? Plywood would be the easiest to apply, and possibly the cheapest, but that doesn't mean it would be best. Any stucco pros with some insight?

- yea after the rip off you need to staple some felt paper (some people call it tar paper) then you neeed to use gavlanised roofing nails to nail up the wire mesh..then apply stucco...I would just nail up some 1/2 plywood..then felt paper then wire then stucco

- Q: Really stone paint the external walls, with ordinary cement board how to deal with the base, what materials to do

- The primary treatment: If the concrete base, in its surface with mechanical spraying or with a broom tossing a layer of 1: 1 porridge-shaped cement mortar (20% of the water with 20 grams of water to make the surface of the solidification, hand breaking , Concrete and brick wall connection nail diamond screen (width 300mm, mesh 10mm × 10mm), nail steel wire mesh before the removal, floating ash and other impurities, steel mesh should be flat and taut.

- Q: How to do the basement of the cement board

- Base repair: in the concrete roof and slab clean, the honeycomb and other large defects in the site of the plaster putty filled with steel scraper compaction, horizontal wiping scraping again (the surface can not scratch the top surface). (Concentration 5 = 100: 5 ~ 6: 60. Brush Alkaline aqueous solution: with 5μ degrees of caustic soda solution brush twice, if the use of 10μ "With the brush immediately rinse with water, dry and then under the next process.

- Q: Thanks Alex. How much you think I should charge to install each 4x8 sheet of cement board?

- I used to charge 2.50$ a s/f to install board or prep an area. That would include the board , thin set and nails ( or screws)to do it properly. 4x8 cement board is hard to find and heavier the all HE!!, so hire a friend. 3x5 sheets are much easier to handle by yourself. Any questions you can e mail me through my avatar. GL

- Q: I've taken up old linoleum tile, chip board, and two other layers of linoleum to get down to an oak floor in my bathroom. This has a felt-like paper uniformly adhered to it that must have been the backing for the first linoleum layer. I'm going to put down Hardi-backer, then tile. Do I have to take up the old tile backing material before I put down the hardibacker? It's very difficult to remove. Thanks!

- I've done it. And The kind of screws you need are not so specialized. Simple drywall screws. About 5 to 8 bucks for a box depending on their length. Now since you say you have no intention of pulling up the old vinyl flooring, and that the subflooring is plywood, I would seriously reconsider. If you are doing it this way out of sheer laziness, then dont do it at all. Also, why are you using cement backerboard for a floor? This is normally used in areas that will constantly be wet, such as a shower wall, steam room, etc. For the floor, and take it from me as I have done this before, and have worked with pros doing this as well. Rip out the vinyl flooring. Its extra work, but hey, do it right the first time not half... well you get the picture. Then once you have that done, you are left with the bare subfloor, typically Plywood or Particle board. Check to see if it is level first, if this is a new house, check to see if it is level anyways. Now, lay down over lapping layers of roofing paper. They should be overlapped by 4 inches. Nail them in place, dont glue or screw it down. Now that you have a good surface to start with, you can now begin your prep work for laying down your tile. Ok, so now you are probably asking, well, why not just leave the vinyl tile under it all, whats the difference. Well, right now, you may not think that it is, but later on you will. The thickness of that tile, plus the cement backerboard, or roofing paper will not transition decently into your adjacent rooms, and it will not look good. And yes, it will make a big difference. If you have any questions on how to go about laying the tile down, any tips, etc... feel free to ask.

Send your message to us

Fiber Cement Board 6mm Fiber Cement Board 6mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords