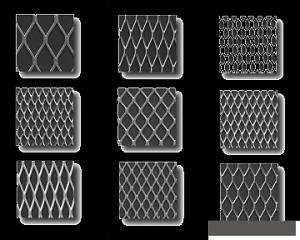

6 Aluminum Mesh

6 Aluminum Mesh Related Searches

6 Aluminum Plate 6x6 Aluminum Plate 6mm Aluminum Plate 6 Micron Aluminum Foil Black Aluminum Mesh Aluminium Modelling Mesh Mic 6 Aluminum Plate 6 Inch Round Aluminum Plate Mic-6 Aluminum Plate Mic 6 Cast Aluminum Plate Aluminum Grate Mesh Mic6 Aluminum Plate 6 Oz Aluminum Foil Cups 6101 T6 Aluminum Plate T6 Aluminum Plate Alcoa Mic 6 Aluminum Cast Plate 6061 T6 Aluminum Sheet Mic 6 Aluminum Tooling Plate Mic6 Cast Aluminum Plate Aluminum T6 6061 Mic 6 Aluminum Plate Suppliers Mic 6 Aluminum Jig Plate 60 Aluminum Plate 6160 Aluminum Plate 5 16 Aluminum Plate Mic 6 Aluminum Plate Specs 5 Aluminum Plate 6061-T6 Aluminum Plate Expanded Aluminum Foil Mesh 6082 T6 Aluminum Plate6 Aluminum Mesh Supplier & Manufacturer from China

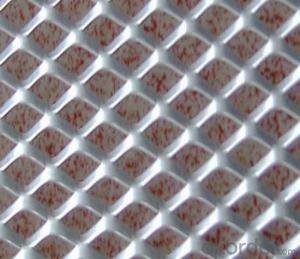

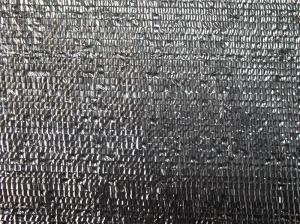

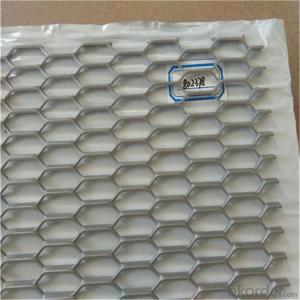

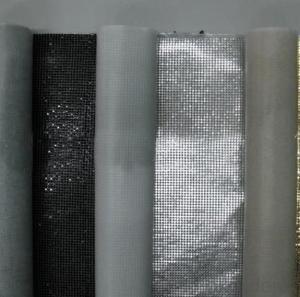

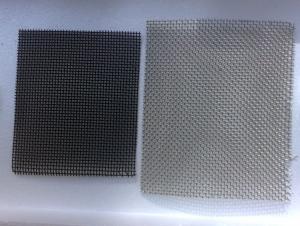

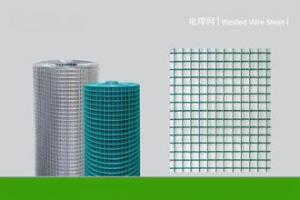

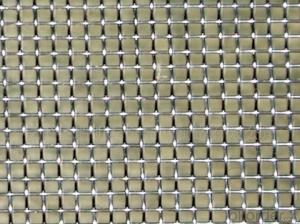

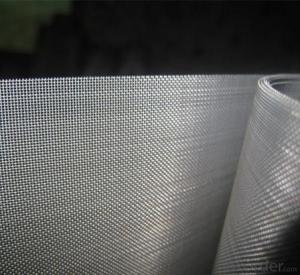

6 Aluminum Mesh is a versatile product that includes various types of aluminum woven wire mesh, expanded metal mesh, and perforated metal mesh. These products are widely used in numerous industries due to their durability, corrosion resistance, and lightweight properties. They can be found in applications such as filtration, ventilation, construction, and agriculture, where their strength and flexibility make them an ideal choice for a multitude of tasks.The 6 Aluminum Mesh is utilized in a broad range of scenarios, from industrial settings to residential applications. For instance, in the construction industry, it is commonly used for reinforcement in concrete structures, while in agriculture, it serves as an effective barrier for protecting crops from pests. In addition, it is employed in filtration systems to separate solid particles from liquids or gases, and in ventilation systems to allow air flow while preventing the entry of debris. The diverse applications of 6 Aluminum Mesh make it a valuable resource for various sectors.

Okorder.com is a reputable wholesale supplier of 6 Aluminum Mesh, boasting a substantial inventory that caters to the needs of different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 6 Aluminum Mesh products they offer meet the highest standards. Their extensive stock allows customers to find the specific type of aluminum mesh that suits their requirements, making Okorder.com a one-stop solution for all 6 Aluminum Mesh needs.

Hot Products