6 Ft Aluminum Coil Mirror Finished 6061 Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

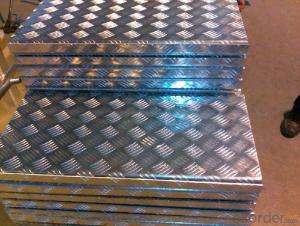

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

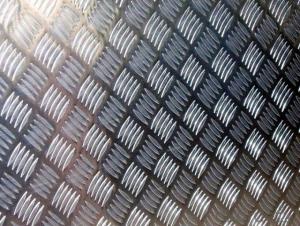

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

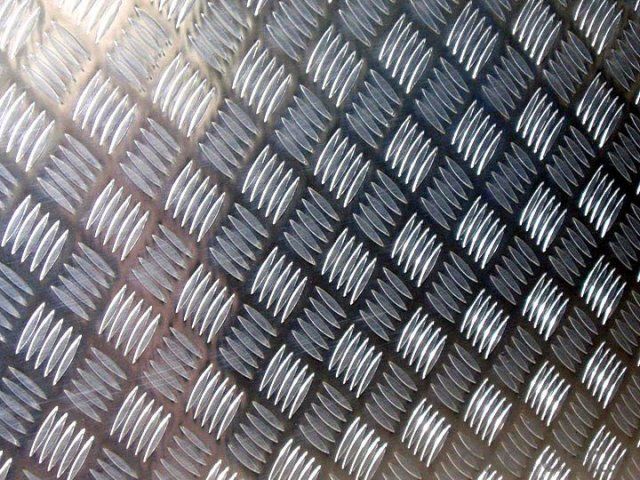

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing or packaging industries. Aluminum is a widely used material in the food industry due to its excellent properties such as being lightweight, corrosion-resistant, and having good thermal conductivity. It is also impermeable to moisture, oxygen, and light, which helps to preserve the quality and freshness of food products. Additionally, aluminum sheets can be easily formed into various shapes and sizes, making them versatile for different packaging requirements.

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: How is aluminum sheet made?

- Aluminum sheet undergoes a rolling process to be manufactured, known as rolling. This process entails passing a preheated aluminum ingot through a succession of rolling mills. The initial step involves heating the ingot to a specific temperature to enhance its malleability. Once heated, the ingot is then fed through a sequence of rolling mills, wherein it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it undergoes compression and elongation, resulting in a thinner and longer sheet. This process is repeated multiple times, with each pass further reducing the sheet's thickness. To maintain the desired thickness and dimensions, the sheet is periodically subjected to annealing. This process involves heating the sheet to a specific temperature and gradually cooling it. Annealing helps alleviate internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and either cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that finds applications in various industries, including construction, automotive, packaging, and electrical appliances.

- Q: Explain the distinction between aluminum sheets based on their thickness.

- <p>Aluminum sheets with different thicknesses primarily differ in their strength, weight, and applications. Thicker sheets offer greater strength and rigidity, making them suitable for structural applications or heavy-duty uses. In contrast, thinner sheets are lighter and more flexible, ideal for applications requiring formability or where weight is a concern, such as in the automotive or aerospace industries. The choice of thickness depends on the specific requirements of the project, including load-bearing needs, durability, and aesthetic considerations.</p>

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and durable material that has excellent corrosion resistance properties, making it suitable for ventilation applications. It can be easily formed and fabricated into various shapes and sizes, allowing for the customization of ventilation components. Additionally, aluminum is a good conductor of heat, which can be beneficial for HVAC systems that require efficient heat transfer.

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring. Aluminum sheet is primarily used for structural and decorative purposes due to its lightweight and corrosion-resistant properties. However, aluminum wire, which has different characteristics and is specifically manufactured for electrical applications, can be used for electrical wiring. Aluminum wire was commonly used in the past, but due to concerns about its conductivity, durability, and potential fire hazards, it has been largely replaced by copper wire in residential and commercial electrical installations. Copper wire is preferred for its superior conductivity and lower risk of developing loose connections or overheating.

- Q: I'm about to fix the aluminum wiring in my house using Alumiconn connection, so I know that every outlet and switch plate need to be done, do the light fixtures need to be done as well? And also does anything need to be done with the main circuit breaker?

- Normally, the houses are ceiling with copper wires on the walls instead of aluminum. Because of safe secure and also cost effective. Better to replace all the things.

- Q: Are aluminum sheets suitable for electrical transformers?

- Indeed, electrical transformers can certainly make use of aluminum sheets. Aluminum, being a highly conductive material, presents numerous benefits when employed in transformers. Primarily, its electrical resistance is lower in comparison to other materials such as copper, enabling efficient transmission of electrical energy. Consequently, this leads to reduced energy losses and enhanced overall performance. Furthermore, aluminum possesses the advantage of being lightweight, rendering it easier to handle and install. Moreover, it is also more economical than copper, thus making it the preferred option for extensive transformer applications. All in all, aluminum sheets offer a dependable and effective resolution for electrical transformers.

- Q: Which is good, aluminum curtain wall?

- Aluminum veneer manufacturers preferred Beijing Jinsheng Aluminium Industry Co. Ltd., it is very important to choose a single aluminum plate manufacturers, Beijing Jinsheng Aluminium Industry Co. Ltd is a professional manufacturer of aluminum veneer, advanced CNC equipment, first-class fluorocarbon spraying line, is your trusted manufacturer of aluminum veneer, aluminum veneer of large manufacturers, advanced technology, advanced technology and to undertake all types of single aluminum plate engineering, quality assurance, price concessions.

- Q: Is it possible to utilize aluminum sheets for the construction of outdoor advertising billboards?

- <p>Yes, aluminum sheets are commonly used for outdoor advertising billboards due to their durability, lightweight, and resistance to weather conditions. They are easy to install, maintain, and can be printed with high-quality graphics. Additionally, aluminum's corrosion resistance makes it a sustainable choice for long-term outdoor use.</p>

Send your message to us

6 Ft Aluminum Coil Mirror Finished 6061 Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords