Braided Aluminum Wire with The Most Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

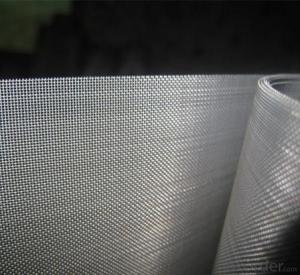

1.Structure of Braided Aluminum Wire Description:

Aluminum alloy wire characteristics: acid, corrosion resistance, toughness, strength, high temperature of 120 degrees Celsius does not fade. Mainly used in construction, handicrafts, weaving nets, communications equipment, medical equipment and brushes, cables, filters, high pressure pipe and other industries.

Aluminum Alloy Wire , Bright color and excellent electrical conductivity, good tensile strength and elongation, light density, etc.

Al-Mg Alloy Wire can be used for braiding and shielding in flexible coaxial cable, a variety of audio and video cable, vehicle signal cable, network cable, data transmission cables and so on.

2.Main Features of the Braided Aluminum Wire:

Conductivity: above 35%

Surface: smooth

Tensile strength: 230-450MPA

Elongation:7--15%

Diameter: 0.12-1.17mm large size is possible if you request

ABS spool

3. Braided Aluminum Wire Images

4. Braided Aluminum Wire Specification

Nominal Diameter | Resistivity | Measured Resistance | Density | Conductivity | Annealed | Hard | |||

20℃ | 20℃ | 20℃ | 20℃ | Elongation | Tensile Strength | Elongation | Tensile Strength | ||

AWG | Φ/MM | ≤Ω.km/m | ≤Ω/km | g/cm | ≥% | ≥% | ≥MPa | ≥% | ≥MPa |

36 | 0.127 | 49

| 3947 |

2.78

| 35

| 8 | 210 | 1 | 330 |

35 | 0.143 | 3113 | 8 | 1 | |||||

34 | 0.16 | 2486 | 8 | 1 | |||||

33 | 0.18 | 1964 | 8 | 1 | |||||

32 | 0.202 | 1560 | 10 | 1 | |||||

31 | 0.227 | 1235 | 10 | 1 | |||||

30 | 0.255 | 979 | 10 | 1 | |||||

29 | 0.286 | 778 | 10 | 1 | |||||

28 | 0.321 | 617 | 12 | 1 | |||||

27 | 0.361 | 488 | 12 | 1 | |||||

26 | 0.405 | 388 | 12 | 1 | |||||

25 | 0.455 | 307 | 12 | 1 | |||||

24 | 0.511 | 243 | 12 | 1 | |||||

23 | 0.573 | 193.8 | 12 | 1 | |||||

22 | 0.643 | 153.9 | 12 | 1 | |||||

21 | 0.723 | 121.7 | 12 | 1 | |||||

20 | 0.812 | 96.5 | 12 | 1 | |||||

19 | 0.912 | 76.5 | 12 | 1 | |||||

18 | 1.024 | 60.7 | 12 | 1 | |||||

17 | 1.17 | 48.1 | 12 | 1 | |||||

16 | 1.291 | 38.1 | 12 | 1 | |||||

15 | 1.45 | 30.2 | 12 | 1 | |||||

14 | 1.628 | 24 | 12 | 1 | |||||

13 | 1.828 | 19 | 12 | 1 | |||||

12 | 2.053 | 15.1 | 12 | 1 | |||||

11 | 2.305 | 12 | 12 | 1 | |||||

10 | 2.588 | 9.5 | 12 | 1 | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A professional manufacturer and exporter for aluminum wire screens and related products. We have more than 100 sets machines. Based on research and development, production and sales of aluminum alloy wire screen products, we are the largest supplier in our area.

②How about product quality?

The quality of products is the key of enterprise survival. We are ISO9001:2008 certificated manufacturer,

③How about the delivery time?

The customer’s needs is delivering on time, rather than an excuse. We will make a production plan before producing, and the sales will regular inform the production schedule and process to the customer.

- Q: Monel wire mesh what material?

- Monel wire mesh is a kind of sea water, chemical solvent, ammonia sulfur and chlorine, hydrogen chloride, various acid media such as sulfuric acid, hydrofluoric acid, hydrochloric acid, phosphoric acid, organic acid, alkali, salt and molten salt has good resistance to the corrosion resistance of nickel based alloy material.

- Q: Recently in doing the screen type web site optimization, screen classification is very messy, how to optimize the classification?

- Can do separate, do stand, do stand group, or can according to material, function, effect and so on classification, do ranking a web site a little difficult

- Q: How many degrees of high temperature iron chromium aluminum wire

- Stainless steel also has high temperature resistance to 310S and so on

Send your message to us

Braided Aluminum Wire with The Most Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords