Black Aluminum Mesh

Black Aluminum Mesh Related Searches

Black Aluminum Plate Black Aluminum Coil Aluminum Diamond Mesh Black Anodised Aluminium Sheet Black Aluminum Diamond Plate Aluminium Modelling Mesh Black Aluminum Tread Plate Black Wrap Aluminum Foil 6 Aluminum Mesh Black Anodized Aluminum Plate Black Diamond Plate Aluminum Matte Black Aluminum Foil Black Aluminum License Plate Black Anodized Aluminum Foil Aluminum Grate Mesh Black Aluminum Checker Plate Aluminum Black Diamond Plate Black Owned Aluminum Foil Black Aluminum Flashing Coil Black Aluminum Foil Roll Cold Forming Aluminum China Black Aluminum Coil Expanded Aluminum Foil Mesh Black Aluminum Flat Stock Black Aluminum Foil Walmart Aluminum Resin Polished Aluminum Sheet Stainless Steel Mesh Black Melamine Faced Chipboard Black Metal CladdingBlack Aluminum Mesh Supplier & Manufacturer from China

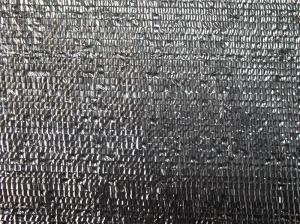

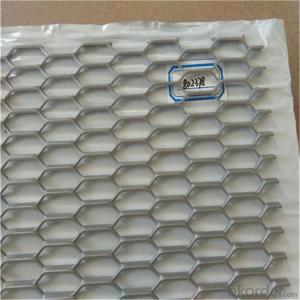

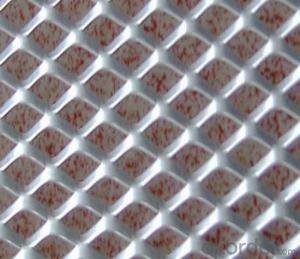

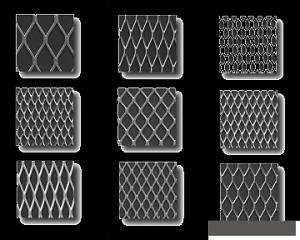

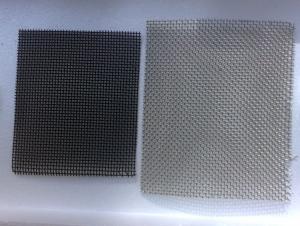

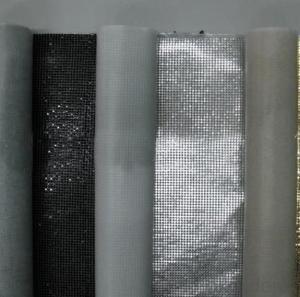

Black Aluminum Mesh is a versatile product made from high-quality aluminum material, designed to meet various industrial and commercial needs. This durable and lightweight mesh is known for its corrosion resistance, strength, and aesthetic appeal, making it a popular choice for a wide range of applications. It is commonly used in construction, agriculture, and landscaping, as well as for filtration and screening purposes. The mesh's black color not only adds a sleek and modern look but also provides protection against UV rays, ensuring long-lasting performance.In various usage scenarios, Black Aluminum Mesh proves to be a reliable and efficient solution. Whether it's used as a safety barrier, a decorative element, or a protective cover, this product stands out due to its robustness and adaptability. It can be easily cut and shaped to fit specific requirements, making it a favorite among professionals and DIY enthusiasts alike. Additionally, its non-flammable nature and resistance to extreme temperatures make it suitable for both indoor and outdoor applications, offering a practical and cost-effective solution for various projects.

Okorder.com is a reputable wholesale supplier of Black Aluminum Mesh, boasting a large inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each order is delivered promptly and in perfect condition. By offering competitive prices and excellent service, Okorder.com has established itself as a trusted source for Black Aluminum Mesh, making it easier for businesses and individuals to access this valuable product.

Hot Products