Full-Coloured Rolled Black Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

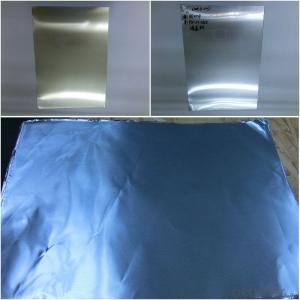

Specification:

Alloy: AA1050, 1060, 1100,AA3003, 3005, 3015, 5052, 5754, 5083,8011, etc

Temper: H14/16/18/22/24/32,HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm (Can be slitted)

Inner Diameter:508MM

Coil Weight:500kg-3000kg(Max.)

Application:Foil stock, Circles, Roofing, Can stock, Marine plate,Anti-slipery purpose in vehicles, packing and appliance.

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail:

Carton ,Woodenpallet with plastic protection packing ,standard seaworthy packing or as yourrequest.

Production Capacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Production Line:

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 days after client’s deposit

- Q: Can aluminum coils be used in electrical transformers?

- Electrical transformers can indeed utilize aluminum coils. Although copper is typically the preferred material for transformer windings, there has been a growing trend towards utilizing aluminum due to its cost-effectiveness and lighter weight. Distribution transformers, which are smaller in size and operate at lower voltages, often employ aluminum coils. However, it is important to consider certain factors when using aluminum coils in transformers. Aluminum has a lower conductivity than copper, necessitating larger cross-sectional areas for the aluminum coils to compensate for this difference. Furthermore, aluminum has a higher coefficient of thermal expansion compared to copper, requiring proper precautions to accommodate the differential thermal expansion between the aluminum windings and other transformer components. In conclusion, aluminum coils can be suitable for specific transformer applications, but it is crucial to meticulously execute the design and manufacturing process to ensure optimal performance and reliability.

- Q: when ferrous sulfate is poured into an aluminium can, holes appear in the can. Why?

- aluminum reacts via a redox reaction with iron(II): 3 Fe2+(aq) + 2 Al(s) --- 3 Fe(s) + 2 Al3+(aq)

- Q: What is the typical heat transfer coefficient for aluminum coils?

- The typical heat transfer coefficient for aluminum coils can vary depending on various factors such as the specific application, coil design, and operating conditions. However, a commonly observed range for the heat transfer coefficient of aluminum coils is around 50 to 250 W/m2K.

- Q: For an intake manifold on a car, as far as increasing the inlet air temperature which is better steel or aluminum? Assuming the cylinder heads are aluminum, and half the thickness of steel is used versus aluminum. I know that steel has a lower heat capacity than aluminum, so does this mean even in this case the steel will heat up quicker and disperse the heat into the inlet air more than aluminum? Basically which material will keep the inlet air as low as possible. I know certain plastics are better than both, but I'm just curious about these two metals. Thank you.

- Increasing heat temperature (Highest point) must be less than melting point of the Aluminum (1221 degree Fahrenheit).Now factor of the weight and stabilizing is important to choose the metal in that section .Aluminum is like fire cricket during melting and if be in flounce of the over heating my cause lot of damages .

- Q: Can aluminum coils be used for electrical conductivity purposes?

- No, aluminum coils cannot be used for electrical conductivity purposes. While aluminum is a good conductor of electricity, it is not suitable for use in coils specifically designed for electrical conductivity. Aluminum has a relatively high resistance compared to other materials such as copper or silver, which are commonly used for electrical conductivity purposes. Additionally, aluminum has a lower melting point than copper, which can lead to overheating issues when used in coils for high electrical currents. Therefore, it is more common to use materials like copper or silver for electrical conductivity purposes, especially in applications where high conductivity and low resistance are required.

- Q: why do we use copper more than aluminum? give some characteristic of copper that makes it better then aluminum?

- Copper is: -harder to oxidize -more ductile -better conductor of electricity -has a longer 'lifespan'

- Q: I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- Hi. You need a spherical tip on, say, a mig welder to be successful when welding aluminum. Spreads out the heat better.

- Q: How do aluminum coils compare to steel coils?

- Aluminum coils and steel coils have distinct characteristics that set them apart in terms of strength, weight, corrosion resistance, and cost. In terms of strength, steel coils generally have a higher tensile strength than aluminum coils. This means that steel coils can withstand greater stress and pressure without deforming or breaking. However, aluminum coils still possess sufficient strength for many applications and can be reinforced or designed for specific purposes. Weight is a significant factor when comparing aluminum and steel coils. Aluminum is a lightweight metal, approximately one-third the weight of steel. This lightweight property makes aluminum coils more advantageous in applications where weight reduction is critical, such as in transportation industries or aerospace. When it comes to corrosion resistance, aluminum coils outperform steel coils. Aluminum naturally forms a protective oxide layer that prevents further corrosion. On the other hand, steel is susceptible to rust and requires additional coating or treatment to enhance its corrosion resistance. This makes aluminum coils a preferred choice in coastal or humid environments where corrosion can be a major concern. Cost is another key consideration. Aluminum coils often have a higher initial cost than steel coils due to the higher cost of raw materials and manufacturing processes. However, the overall cost may vary depending on factors like transportation, maintenance, and lifespan. Aluminum coils tend to have lower maintenance costs and longer lifespans due to their corrosion resistance, which can offset the initial investment in the long run. In summary, aluminum coils offer several advantages over steel coils, including lower weight, superior corrosion resistance, and potential long-term cost savings. However, steel coils still boast higher tensile strength and may be the preferred choice in applications that require maximum strength or have a lower budget. Ultimately, the choice between aluminum and steel coils depends on the specific requirements and considerations of the intended application.

- Q: The user is asking if it's possible to create furniture using aluminum coils.

- <p>Yes, you can use aluminum coils to make your own furniture. Aluminum is a versatile material known for its strength, durability, and lightweight properties, making it suitable for furniture construction. You can bend and shape aluminum coils to create unique designs for chairs, tables, or shelving. However, it's essential to have the right tools and skills for cutting, bending, and joining the coils. Ensure you follow safety precautions when working with metal, and consider the structural integrity and weight distribution of your design to ensure the furniture's stability and longevity.</p>

- Q: Can aluminum coils be used for industrial piping?

- Yes, aluminum coils can be used for industrial piping. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various industrial applications, including piping systems.

Send your message to us

Full-Coloured Rolled Black Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords