Aluminum Coil 5052 Price - Mill Finish Coil 5052 Aluminum Alloy Properties

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

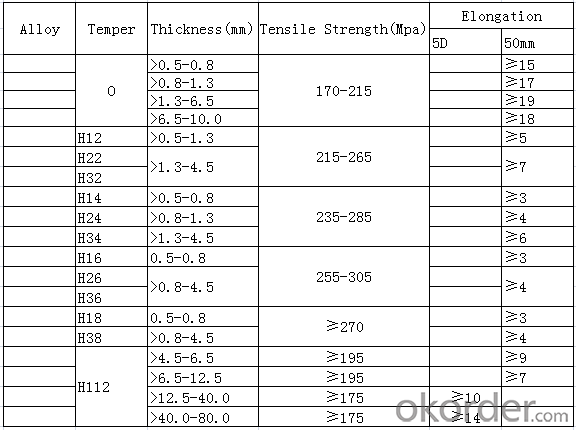

Mill Finish Coil 5052 Aluminum Alloy Properties

l Product Description

Aluminum Coil - Specifications

- Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

Aluminum Coil - Tolerances

- Manufactured in compliance with the main international specification and standards.

- Tighter tolerances are available upon request.

Aluminum Coil - Surface Conditions

- Mill, Matte, Bright and Brushed

- Cleaning and degreasing

- Surface oiling

- Customized surface conditions available upon request.

Aluminum Coil - Special Processing

- Cut-to-Length

- Tension Leveling

- Paper Interleaving

- Fine grain, minimum earring, anodizing quality

l Product Specification:

The Composition Aluminium Coil 5052

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

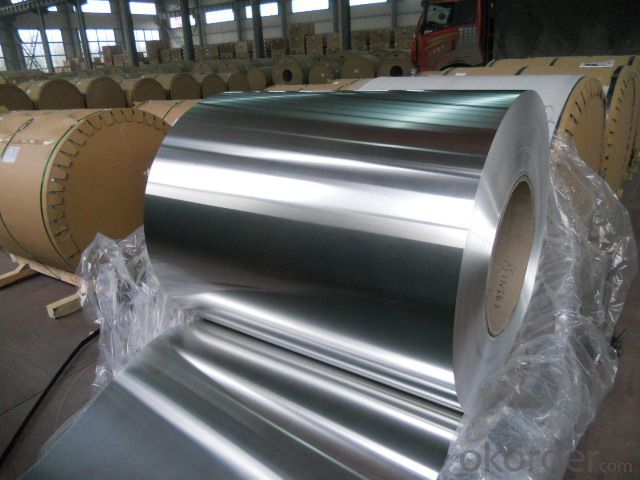

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Are aluminum coils affected by magnetic fields?

- Yes, aluminum coils can be affected by magnetic fields to a certain extent. Aluminum is a non-magnetic material, meaning it does not possess any inherent magnetic properties. However, when exposed to strong magnetic fields, aluminum can experience an induced magnetic field due to a phenomenon called electromagnetic induction. This can result in a slight attraction or repulsion between the aluminum coil and the magnetic field, although the effect is generally weaker compared to materials with magnetic properties, such as iron or steel. It is important to note that the degree of interaction between aluminum coils and magnetic fields depends on several factors, including the strength and proximity of the magnetic field, the shape and size of the coil, and the specific composition of the aluminum alloy used in the coil.

- Q: What are the different grades of aluminum used in coil manufacturing?

- In coil manufacturing, various grades of aluminum are utilized, each possessing its own unique properties and applications. The commonly employed grades encompass 1100, 3003, 5052, and 6061. Grade 1100 is an aluminum of commercial purity, exhibiting remarkable corrosion resistance and favorable formability. It finds frequent usage in chemical equipment, heat exchangers, and food handling equipment. Grade 3003, a non-heat treatable alloy, showcases commendable corrosion resistance and moderate strength. It is often employed in cooking utensils, roofing, and general sheet metal work. Grade 5052, an alloy of high strength, displays excellent formability and corrosion resistance. It finds extensive application in marine sectors, such as boat hulls and components, as well as in automotive parts and appliances. Grade 6061, a heat treatable alloy, boasts exceptional strength and good machinability. It is commonly utilized in structural applications, including aircraft parts, bike frames, and automotive components. These grades of aluminum encompass a wide array of properties and characteristics, enabling manufacturers to select the most suitable grade for their specific coil manufacturing requirements.

- Q: Explain the differences between aluminum coil and aluminum sheet in a few sentences.

- <p>Aluminum coil and aluminum sheet are both flat aluminum products but differ in form and usage. Aluminum coil is a long, continuous roll of aluminum that can be easily unrolled and cut to length, making it ideal for manufacturing processes where the material needs to be fed through machines. It is commonly used in industries such as construction, packaging, and automotive for applications like roofing, siding, and food packaging. Aluminum sheet, on the other hand, comes in flat, rectangular pieces with specific dimensions and is typically thicker than coil. It is used in applications where a solid, non-continuous piece is required, such as in signage, furniture, and decorative elements. The thickness and surface finish can also vary between coils and sheets, with sheets often being available in a wider range of finishes and thicknesses.</p>

- Q: What should pay attention to transporting aluminum coil?

- You must ensure the good property of the aluminum coil.

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum coils.

- <p>Aluminum coils offer several advantages, including high thermal conductivity, which makes them efficient for heat transfer applications. They are lightweight and corrosion-resistant, which enhances their durability and reduces maintenance needs. Additionally, aluminum is a cost-effective material compared to other metals like copper. However, there are disadvantages such as lower strength compared to steel, which may limit its use in high-stress applications. Aluminum also has a higher coefficient of expansion, which can lead to issues in precision applications. Lastly, while it is recyclable, the recycling process can be energy-intensive.</p>

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- If you are using a frying pan on a gas stove - yes. I fold tin foil into a strongish ribbon then form the shape I want: hearts, gingerbread men, etc. Make sure the pan is fairly warm before you put the tin foil shape in remove the shape as soon as the pancake is set, but before you flip it. You can trim the little splashes before serving. HOWEVER - there are reusable shapes available at many kitchen supply stores. They are not very expensive are permanent additions to your kitchen.

- Q: How is the welding performance of 3003 aluminum coil?

- 3003 aluminum coil, a kind of rust-proof aluminum, belongs to AL-Mn series alloy. With low intensity (slightly higher than commercial purity aluminum), it cannot endure heat treatment, so cold processing is adopted to increase its mechanical property: high plasticity in annealing and semi-cold hardening, low plasticity in cold hardening, good corrosion resistance., good weldability and bad machinability. It is mainly used for low load part in liquid or gaseous medium requiring high plasticity and good weldability, such as fuel tanks, gasoline or lubricant conduit. It can also be used for liquid containers and other deep drawing small load parts made by deep drawing. Aluminum wire can be used to make the rivet.3003 aluminum sheet has good formability, weldability and corrosion resistance. It is used to process parts which require good formability, corrosion resistance and weldability and lower intensity than 1xxx series alloy, such as such as kitchenware, food and chemical products processing and storage equipment, groove and tank to transport liquid product, pressure vessel and pipe processed from thin plate, cooling fin, make-up board, photocopier rollers and ship material.

- Q: i have some questions about aluminum can recycling??:how much can you get from doing that??where can i take them in indianapolis, in???and what else could i recycle??its good for the earth and i need some money!! :) :D thanks!!! :)

- Aluminum is not biodegradable. Also making aluminum from ore requires a lot of energy. Recycling cans is easy and saves a whole lot of energy reducing green house gases. Recycling aluminum also reduces the mining required to dig up aluminum ore thereby saving the land and stopping pollution from mine run-off.

- Q: Are aluminum coils suitable for heat sinks?

- Indeed, aluminum coils are well-suited for heat sinks. The reason for aluminum's popularity in this regard lies in its exceptional thermal conductivity and affordability. Its remarkable thermal conductivity permits efficient heat transfer from a heat source to the heat sink's fins, which effectively dissipate the heat into the surrounding environment. Moreover, aluminum possesses the advantageous qualities of being lightweight and easily moldable into different shapes, thereby rendering it a versatile material for heat sink purposes. All in all, aluminum coils prove to be a fitting option for heat sinks due to their ability to effectively dissipate heat and their cost-effectiveness.

- Q: Is it possible to utilize an aluminum coil as a light source?

- <p>Aluminum coil itself cannot be used as a light source. Aluminum is a good conductor of electricity but does not emit light when electrified like certain materials can. To create light, materials like tungsten in incandescent bulbs or phosphors in fluorescent lights are used. Aluminum coils can, however, be used in conjunction with other components in lighting fixtures, such as in heat sinks to dissipate heat from LEDs, but they do not produce light directly.</p>

Send your message to us

Aluminum Coil 5052 Price - Mill Finish Coil 5052 Aluminum Alloy Properties

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords