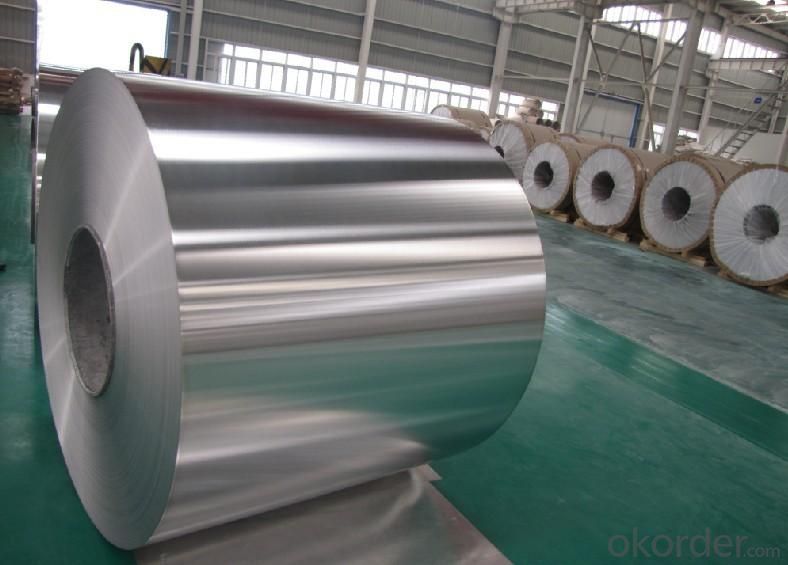

Color Coated Aluminum Coil AA5052 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color Coated Aluminum Coil AA5052 Aluminum Alloy

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Description

Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.1mm to 1.2mm |

Width | Standard width:1240mm, 1270MM |

Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia:1200mm |

Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

outer diameter: 1200mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

Protective film | As per customer’s request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

Weight | As per customer’s request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

4. FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: How to clean up the cigarette cages?

- For it, buckle board cheap, anyway, keel what are playing well, the mouth is not on the line

- Q: Is the ceiling with an aluminum plate?

- Plastic buckle home decoration has been eliminated. Easy to deformation, and the long time will be aging. Aluminum slabs are now basically using integrated ceiling, color and style more points. Aluminum slab plate is generally used in the kitchen, bathroom, because of its material reasons, not rust, durable, easy to clean, easy maintenance, the general proposal with the side buckle, so easy to disassemble; living room, bedroom, do not use aluminum buckle, Grade, if you want to save costs that do not ceiling, keep the original high, buy a nice light on the line

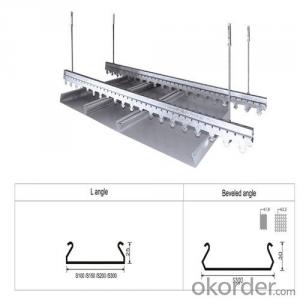

- Q: How to wrap the pipe with aluminum buckle?

- Construction process: Install the plastic gusset: add the sun on the wood keel, directly from the bottom of the buckle up into the installation, the method is simple, but not beautiful appearance, and the surrounding wall is not very match. Installation of aluminum-plastic plate: in the wooden keel on the nail nine PCT board, and then glue the aluminum-plastic plate stick to it. There are many colors of aluminum-plastic plate, decorated close to the effect of the disk, but the aluminum-plastic plate angle is easy to crack, so to use thicker plate.

- Q: How much is the price of an inch? Pack material

- Expensive more than 600 of a square, the specific brand is imported.

- Q: Is the aluminum slab ceiling applicable to the corridor?

- Yes, there are many colors or types to choose from. There are many manufacturers are beginning to produce panoramic top, that is, all the indoor space can be used.

- Q: Can the ceiling of the balcony be used? My house is on the top floor, the balcony ceiling is glass. With aluminum cords hanging ceiling summer high temperature buckle plate will not deformation ah?

- Can be used is the aluminum plate will be more hot aluminum is not insulated

- Q: Is the living room suitable for aluminum slabs?

- It is not suitable for this space application material.

- Q: Aluminum buckle board a side of the edge of how fixed

- Usually the first installation of the keel, keel fixed well, you can insert the aluminum plate in the keel of the gap, and then firmly fixed, it is important to note that the aluminum plate in the installation process must be Gently, or is very easy to damage.

- Q: How to disassemble the ceiling

- Aluminum slabs are decorated with triangular keel card, with plastic sucker (supermarket there) can be sucked, and installed along the press on the line.

- Q: The top of the kitchen did not line, like the largest reduction in space, at least how high Is the kitchen

- Two probabilities, one is the commercial kitchen. Commercial kitchen, then taking into account the new wind, exhaust, fire pipe will be arranged at the top of the kitchen.

Send your message to us

Color Coated Aluminum Coil AA5052 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords