Aluminum Ceiling Tiles with Goods Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: Aluminum Ceiling Tiles

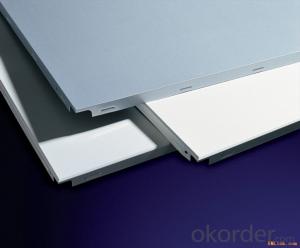

Material: Aluminum sheet

Thickness: 0.45-1.0mm

System: Metric or British System

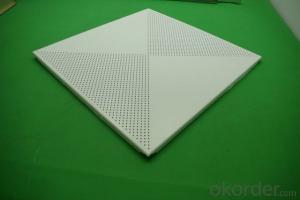

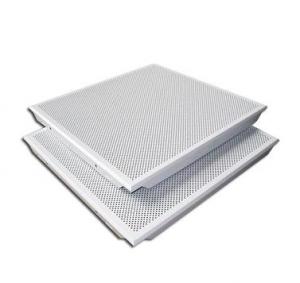

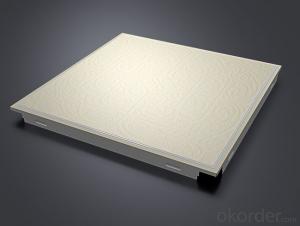

Model: Clip in, Lay in, Lay on

Edge height: 8mm, 10mm, 18mm

Surface: Powder coating, Pre-paint

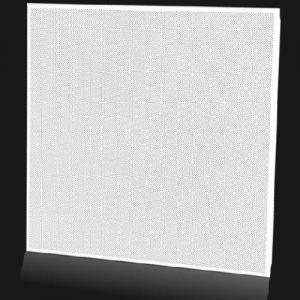

Perforation: Perf. 1.8mm, 2.3mm

NRC: 0.5~0.65

CAC: 30~40

Fire proof: B1

Function: Fireproof, Heat Insulation, Moisture-Proof, Mould-Proof, Sound-Absorbing, Soundproof, Waterproof

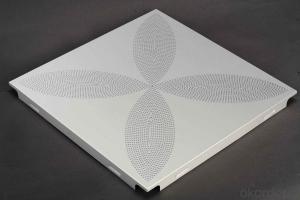

Feature: Artistic Ceilings, Integrated Ceilings, Perforated Ceilings

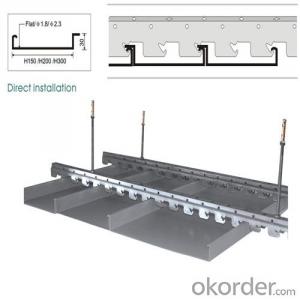

EASY PLENUM ACCESS

The panels can be easily demounted by hand allowing easy and full access to services and installation in the plenum.

DESIGN FLEXIBILITY

Aluminum ceiling panel appearance provides interesting possibilities for spatial room designing.

The ceiling panel show different style pattern and shape, which engage you match your design.

A range of colors and finishes is standard available and special colors upon request.

DURABILITY

Square panel ceilings are manufactured from durable roll formed aluminum (0.5/0.6mm) or steel 0.5 mm coil, finished with a polyester paint to provide a long, low maintenance life. The coating is stove-enamelled in a continuous coil coating process ensuring uniform coating thickness and absolute adhesion.

PRODUCT CHARACTERISTIC

1) Surface smoothness and easy cleaning ;

2) Flexible suspension system makes each ceiling tile easily installed and disconnected;

3) Easy to match lamps or other ceiling parts;

4) Surface color can be stable for 10 years by indoor use;

5) Function: Acoustical, Fireproof, Waterproof, Washable, Light reflect.

- Q: Aluminum veneer, aluminum buckle plate price What is the difference? What are the specifications?

- Aluminum plate thickness is generally 0.5mm to 1.2mm aluminum alloy plate. Mainly used for ceiling ceiling

- Q: What sound insulation is good? What is the effect of aluminum foam?

- You can choose aluminum foam material, it is light material, high temperature, fire performance, corrosion resistance, sound insulation effect.

- Q: Mirror aluminum ceiling for the kitchen is good, choose which brand of high cost, it will absorb fumes?

- 1, aluminum ceilings can reflect the glare, giving people uncomfortable feeling; 2, ceilings with ceramic more compliance; 3, ceiling materials and decoration style will be better to match some of the other ... ... In addition, the current kitchen integration ceiling reputation Larger is an allies.

- Q: What brand of aluminum plate is good, which brand of aluminum buckle plate is better?

- 1. AIA (home ceiling industry leader brand, Zhejiang Jiaxing Anbang Electric Co., Ltd.) 2. Aopu (bathroom ceiling leading brand, Hangzhou Aopu Wei Kitchen Technology Co., Ltd.) 3. Rong Sheng (China's well-known trademarks, the top ten brands, Guangdong Rongsheng Electric Co., Ltd.) 4. Baolan (integrated ceiling top ten brands, Zhejiang Jiaxing Wang shop image business) 5. Tuscany (integrated ceiling top ten brands, intelligent integrated ceiling founder, from Italy) 6. Chu Chu (ceiling top ten brands, OKorder Chu Qiao bathroom Electric Co., Ltd.) 7. Austrian (ceiling top ten brands, Zhejiang famous brand, Zhejiang Ouhua Electric Co., Ltd. 0 8. Vantage (China Famous Brand, Vantage Group China Vantage Heating Electric Co., Ltd.) 9. Character (integrated ceiling top ten brands) 10. Merkel (integrated ceiling top ten brands, Zhejiang Jiaxing Meier Kate Wei Kitchen Technology Co., Ltd.)

- Q: What should I pay attention to when buying an aluminum plate?

- (1) to view its aluminum thickness. The thickness should not be less than 0.6 mm, or likely to cause the phenomenon of collapsed waist. When choosing to pay attention to whether the business through the thickening of the paint layer to increase the overall thickness, this aluminum plate do not buy. (2) check the true quality of the material to prevent illegal manufacturers of stainless steel fake aluminum, pure aluminum or impure aluminum or stainless steel iron, you can use the magnet to verify that pure aluminum does not magnetize, and times Quality aluminum or false aluminum can absorb magnetic. (3) to identify the aluminum plate in addition to pay attention to the surface finish, but also to observe the thickness of the board is uniform, whether double-sided paint, pinch the board feel, flexibility and toughness is good enough.

- Q: Where is the line to be done

- Aluminum plate closed edge is done on the wall, you can use the expansion screw and glue the way fixed fixed edge, and then install the aluminum plate.

- Q: Aluminum buckle ceiling ceiling area is how to count

- If you calculate the area of a piece of gusset, such as 30 cm long, 30 cm wide aluminum gusset plate, an area of 0.3 m * 0.3 m = 0.09 square meters

- Q: How many pieces of aluminum slabs are used for the integrated ceiling

- 5 pieces 20cm multiplied by 1m = 1m?

- Q: Such as the problem, the wet bathroom will be selected because of the aluminum buckle material and the formation of a layer of water droplets, Is not it should choose the sauna board and other wood materials please answer the other experts and the kitchen and before and after the balcony if you choose the aluminum plate should choose what form, Foil

- Will not. Kitchen and bathroom selection of aluminum plate hanging ceiling, is due to the kitchen or bathroom area is relatively small, do not worry about the strength and flatness of the aluminum slab plate problem, coupled with the material itself is generous, not rust, breathability Ye Hao, The price is relatively low reason. Of course, now the above area is not all with aluminum slab to do ceiling, with steel, Caigang, aluminum-plastic plate, plastic buckle plate decoration is also a minority.

- Q: What is the integrated ceiling, aluminum slab ceiling than pvc ceiling which advantages, integrated ceiling which big brand, what are the top ten brands?

- Pvc ceiling High temperature performance, no fire, sound insulation is poor. Electrical convex, very uncoordinated, no overall sense and beauty. Practicality is not strong, can not be arbitrarily disassembled, must have a professional workers to deal with.

Send your message to us

Aluminum Ceiling Tiles with Goods Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords