Perforated Aluminium False Ceiling Lay On Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Function: | Feature: | |||

| Ceiling Tile Shape: | Ceiling Tile Type: | Surface Treatment: | |||

| Metal Ceiling Material: | Key word: | Specification: | |||

| Height: | Thickness: | Perforated diameter: | |||

| Color: | MOQ: | Delivery time: | |||

| Packing: | Certificate: |

Packaging & Delivery

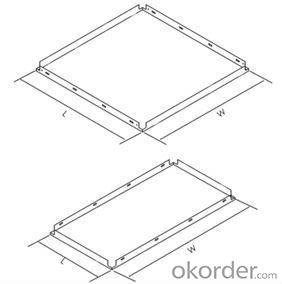

| Packaging Detail: | Aluminium ceiling tile (Lay in) -------------------------------------------------------- 18pcs/carton carton size:625x625x225 340carton/20ft 3182.4m2/20ft 760carton/40HQ 7113.6m2/40HQ Aluminum ceiling Lay in tiles -------------------------------------------------------------- 26pcs/carton carton size:625x625x225 340carton/20ft 2203.2m2/20ft 760carton/40HQ 4924.8m2/40HQ |

| Delivery Detail: | 10days |

Specifications

2014 New fireproof aluminum ceiling

Specification:600*600

Material: Aluminum alloy

Certification:ISO,BV, TUV

Factory price

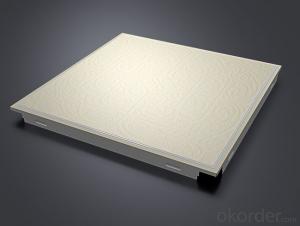

DESIGN FLEXIBILITY CMAX ceiling panel appearance provides interesting possibilities for spatial room designing. The ceiling panel show different style pattern and shape, which engage you match your design. A range of colours and finishes is standard available and special colours upon request.

EASY PLENUM ACCESS The panels can be easily demounted by hand allowing easy and full access to services and installation in the plenum.

DURABILITY Square panel ceilings are manufactured from durable roll formed aluminum (0.5/0.6mm) or steel0.5 mm coil,finished with a polyester paint to provide a long ,low maintenance life .

Product characteristic: 5)Function: Acoustical, Fireproof, Waterproof, Washable, Light reflect, |

1) Our clip in aluminum ceiling:

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

2) Specifications:

| Specification | Thickness | Height | Legend |

| 300×300mm | 0.4-1.0mm | 19mm(short edge) 25mm(High edge) |  |

| 300×450mm | |||

| 300×600mm | |||

| 300×1200mm | |||

| 400×400mm | 0.5-1.2mm | ||

| 500×500mm | |||

| 600×600mm | |||

| 600×1200mm | |||

| Base materials | Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available | ||

| Surface treatment | Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated | ||

| Type of Surface | Plain plate or perforated plate is selected according to the actual requirements | ||

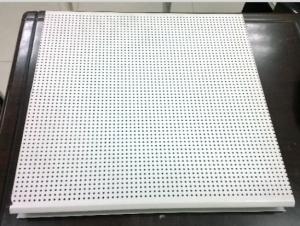

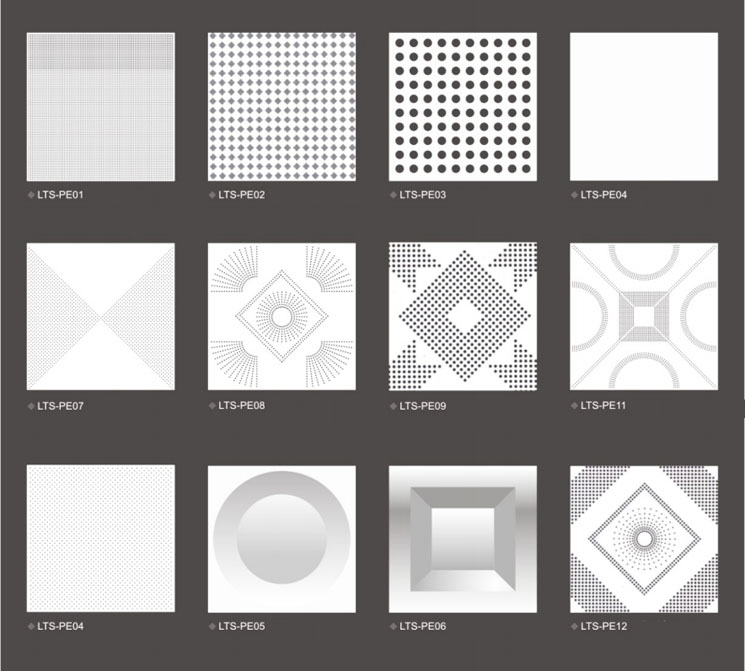

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

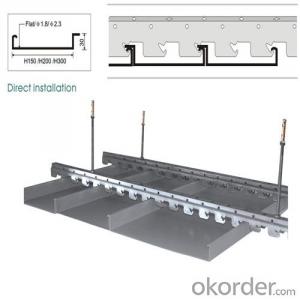

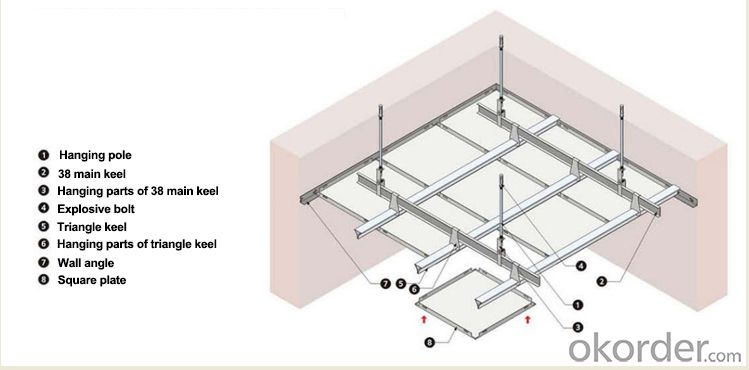

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

- Q: Bathroom and then what the new ceiling with aluminum plate pattern

- Simple: the general kitchen area is too small, the pattern engage in fancy, and view more narrow; not to mention cleaning more convenient.

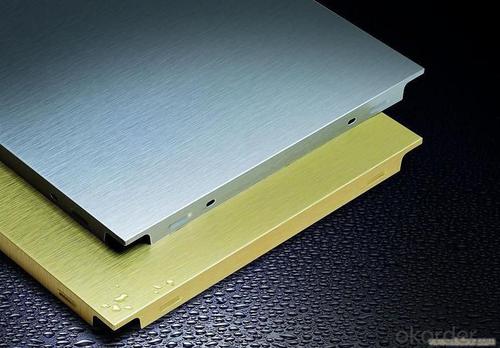

- Q: What is the brushed aluminum plate

- Brushed aluminum is a repeated use of sandpaper to scrap the aluminum plate manufacturing process, the process is divided into de-ester, sand mill, washed three parts. In the aluminum wire drawing process, the anode treatment after the special film technology, can make the surface of the aluminum plate containing a metal composition of the film layer, clearly show every fine silk marks, so that metal matte glowing fine hair Silk glossy. More and more aluminum products are used in the metal shell metal wire drawing process to play a beautiful, anti-erosion effect. So that products both fashion and technology elements. This is one of the reasons why the process is popular.

- Q: What is the keel of aluminum alloy integrated ceiling?

- Large keel with light steel keel, small keel with aluminum alloy light steel keel will do, according to the decorative panel selection of small keel type. Generally there is a matching.

- Q: How to wrap the pipe with aluminum buckle?

- Construction process: Install the plastic gusset: add the sun on the wood keel, directly from the bottom of the buckle up into the installation, the method is simple, but not beautiful appearance, and the surrounding wall is not very match. Installation of aluminum-plastic plate: in the wooden keel on the nail nine PCT board, and then glue the aluminum-plastic plate stick to it. There are many colors of aluminum-plastic plate, decorated close to the effect of the disk, but the aluminum-plastic plate angle is easy to crack, so to use thicker plate.

- Q: Aluminum buckle board a side of the edge of how fixed

- There are a lot of ways to fix a long way to achieve a strong, but not good to do so unless the nails, but in the tiles on the job so it is difficult to do Other methods are; generally more solid I used almost can reach 2 years, After all the adhesive tape with a transparent tape so that all the time can be long. Other uses are simple and fast and the use of up to a year, there are direct tape with glass glue nail rubber, etc.

- Q: Bathroom and kitchen how to choose aluminum buckle ceiling?

- Home improvement, there are two places to consider the installation of aluminum buckle ceiling, one bathroom, one kitchen, then, the choice of aluminum buckle ceiling will take into account.

- Q: Ordinary 600 * 600 aluminum buckle plate integrated ceiling price how much? If i do 300 * 300, the price will be cheaper?

- Ordinary home improvement are generally 300 * 300 600 * 600 is the use of more tooling, such as office buildings, schools, etc. Home improvement is certainly cheaper than the tooling

- Q: What is an aluminum buckle? What place to use it, and gypsum board is different

- Ceiling aluminum slab material after more than 10 years of development, technology is also constantly updated, the first generation of products is gypsum board, mineral wool board; second generation is PVC; third generation of products is metal ceilings. And metal ceilings and aluminum slab plate came from behind, the same day, the current market is also divided into several grades of aluminum slab: the first class of aluminum-magnesium alloy, also contains part of the manganese, the biggest advantage of the material is good antioxidant capacity, At the same time because of the addition of the amount of manganese, in the strength and stiffness has improved, is the best material for the ceiling. The second type of aluminum-manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum-magnesium alloy, but the antioxidant capacity of a slight shortage of the third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are obvious Lower than the aluminum-magnesium alloy and aluminum-manganese alloy, antioxidant capacity in general.

- Q: How is the angle of the aluminum buckle plate installed?

- A lot of glass mirror sticky.

- Q: How to remove the ceiling plate

- Hold up and lift the plate up to 45 degrees and remove it at the diagonal.

Send your message to us

Perforated Aluminium False Ceiling Lay On Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords