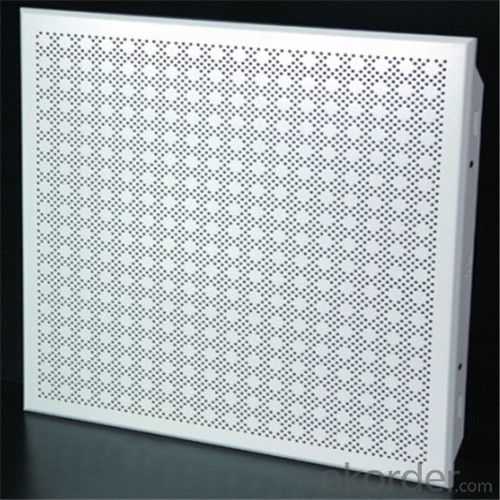

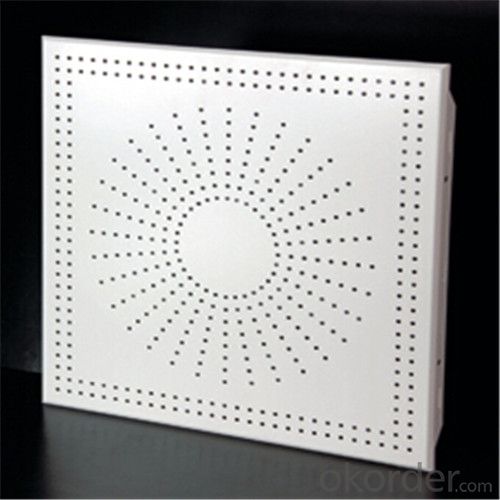

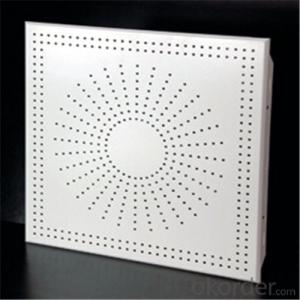

Aluminium Strip False Ceiling Metal Ceiling Fireproof Perforated Aluminum Clip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

we professionally produce aluminum ceiling with high quality paint, different designs, resonable price and dedicated service.

Quick Details

| Type: | Ceiling Tiles | Place of Origin: | Shandong China (Mainland) | Brand Name: | XINHE |

| Model Number: | XH | Function: | Fireproof,Heat Insulation,Moisture-Proof,Mould-Proof,Smoke-Proof,Sound-Absorbing,Soundproof,Waterproof | Feature: | Artistic Ceilings,Integrated Ceilings,Perforated Ceilings |

| Ceiling Tile Shape: | Square | Ceiling Tile Type: | Metal Ceilings | Surface Treatment: | Brushed,Film Coated,Roll Coated,Spray Painted |

| Metal Ceiling Material: | Aluminum,Aluminum Alloy | color: | white,gold,pink,etc | size: | 300x300MM; 600x600MM |

| certification: | SONCAP; CE; SGS; ISO | Item: | Aluminum Ceiling |

Packaging & Delivery

| Packaging Detail: | in carton with export standard |

| Delivery Detail: | within 25 days. |

Specifications

aluminum ceiling:

1,light weight,high rigidity

2,easy install and clean

3,fireproof,anti-rust,moistureproof

ISO; SONCAP;SGS

aluminum ceiling:

metal suspended false ceiling

1,Style: plain, perforated, lay-in, clip-in or special order

2,Surface smoothness, environmental friendly,elegance,very excellent visual extension of space

3,Easy to match lamps or other ceiling parts

4,Nano series and semi-finished products also available

5,Installation:macth with ceiling T-bar(we can supply)

Item name | Aluminum ceiling |

Brand name | XINHE |

Material | Aluminum or Aluminum alloy |

Size | 300x300, 300x600, 600x600,600x1200mm…customized |

Thickness | 0.4-0.8mm,on request |

Height | 17mm,20mm |

Coating | Powder coating,polyester powder coating(10 years guarantee) |

Color | White, blue, pink, yellow...customized |

Feature | Easy install and disassemble,simple structure,good adhesion,anti-corrosion, fireproof,waterproof,rust proof,weather resistance,easy cleaning,sound absorbing, heat insulation, highly recyclable,good plasticity,easy maintenance, durable,anti-ultraviolet, radiation proof… |

Package | Standard carton with XINHE mark, the carton size: 620x320x320mm, 60 pcs per carton. |

Certificate | ISO9001:2000 |

Application | Kitchen,bathroom,living room,office,shopping mall,conference room,laboratory,exhibition hall,airport and so |

- Q: Living room wall is rough wall putty, And part of the rough wall is outside the concrete + 1cm around the cement mortar, and some parts of the gas brick + 1cm outside the cement mortar , Now want to own ceiling, the difficulty is how to install the edge of the wall in the living room wall, rely on glue is not assured, this situation how to do?

- Aluminum-plastic plate Construction process: keel layout and elastic line → installation and leveling keel → installation of aluminum-plastic plate → trim sealing. ?1), the elastic line: to determine the elevation control line and keel layout line, if the ceiling has a variable height, the corresponding part of the variable section should be determined, and then along the elevation line fixed angle aluminum. ?2), to determine the keel position line: According to the size of aluminum-plastic panels and ceiling Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q: How to clean up the cigarette cages?

- It does not matter on the line, this thing can not handle clean.

- Q: How to dismantle the aluminum plate

- The intensity can be pulled out slightly, if it is a strip of the ceiling that pushed from the wall on the edge of a piece of the inside can be taken down, and then followed down, but after all strenuous.

- Q: What is uv aluminum buckle board Uv stands for anything

- UV aluminum plate is UV ink printing aluminum plate, the traditional solvent-based ink printing aluminum plate due to solvent evaporation, dry and slow taste pungent, not environmentally friendly. Ding Yuan ink UV ink printing pattern after the instant dry, no taste more environmentally friendly.

- Q: Home kitchen ceiling, master less card a piece of aluminum plate, said tomorrow to give me a piece of cards, I do not know how to card up?

- That good card, on the buckle up on the line friends

- Q: Under the beam to install aluminum hanging plate ceiling, at least need to stay a few centimeters? (That is, the distance between the aluminum plate and the beam)

- See you install the lights, and if the LED lighting 10 cm is enough, ordinary lighting at least 15 cm, the bathroom installed Yuba to 20 cm.

- Q: Aluminum buckle ceiling ceiling labor costs how much

- The price of the ceiling is mainly different according to the specifications, thickness and quality of the aluminum slab plate. The following are some of the market on the aluminum slab ceiling price: Aluminum slab 300 X 300 (0.6 thick) with labor costs reference price: 60 yuan / m2 Aluminum plate 300 X 300 (0.5 thick) Reference price: 74 yuan / m2 Aluminum screw plate 600 X 600 (0.6 thick) with labor costs reference price: 58 yuan / m2

- Q: Integrated ceiling aluminum slab board know how much knowledge?

- A kind of new home furnishings in the 1990s, mainly used for kitchen and bathroom ceiling works. As the entire process of aluminum slabs to use all-metal build, in the service life and environmental protection capabilities, more superior to PVC materials and steel materials

- Q: What is the angle of the ceiling? What is the inverted angle?

- Corner line is the angle of the edge of the article, most of the T-shaped.

- Q: Aluminum buckle ceiling business does not make money? How much profit margins? Is it good to do a good job or a good distributor

- Aluminum slab business can also be, the specific profit is not clear,

Send your message to us

Aluminium Strip False Ceiling Metal Ceiling Fireproof Perforated Aluminum Clip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords