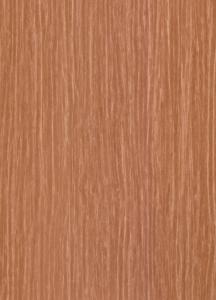

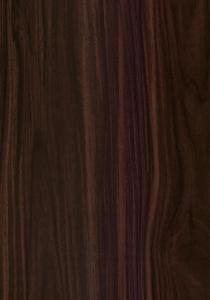

Wooden Texture Coated Aluminum Coil

Wooden Texture Coated Aluminum Coil Related Searches

Textured Aluminum Coil Textured Aluminum Trim Coil Color Coated Aluminum Coil Colored Aluminum Coil Vinyl Coated Aluminum Coil Copper Colored Aluminum Coil Colored Aluminum Trim Coil Powder Coated Aluminum Coil Polished Aluminum Coil Wood Grain Aluminum Coil Embossed Aluminum Coil Buy Coated Aluminum Coil Painted Aluminum Trim Coil China Color Coated Aluminum Coil Vinyl Coated Aluminum Trim Coil Anodized Aluminum Coil Prepainted Aluminum Coil Coil Coated Aluminum Wood Grain Aluminum Trim Coil Pvc Coated Aluminum Coil Aluminum Wire Coil Coil Coating Aluminum Aluminum Voice Coil Custom Rolled Aluminum Coil Aluminum Tubing Coil Aluminum Alloy Coil Copper Aluminum Coil Stucco Embossed Aluminum Coil Coated Aluminum Coil Pe Aluminum Coil PipeWooden Texture Coated Aluminum Coil Supplier & Manufacturer from China

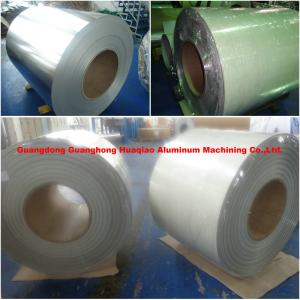

Wooden Texture Coated Aluminum Coil is a unique product that combines the aesthetic appeal of wood with the durability and strength of aluminum. This innovative material is designed to mimic the look and feel of natural wood, while providing the benefits of aluminum in terms of lightweight, corrosion resistance, and low maintenance. The result is a versatile and eco-friendly material that is suitable for a wide range of applications.Wooden Texture Coated Aluminum Coil is widely used in various industries, including construction, interior design, and automotive. It is particularly popular for exterior facades, window frames, doors, and decorative elements due to its ability to withstand harsh weather conditions and maintain its appearance over time. Additionally, it is an excellent choice for furniture, cabinetry, and other interior applications where a wood-like finish is desired but the durability and low maintenance of aluminum is needed.

Okorder.com is a leading wholesale supplier of Wooden Texture Coated Aluminum Coil, offering a vast inventory of this high-quality product. With a commitment to providing exceptional customer service and competitive pricing, Okorder.com ensures that customers can access the Wooden Texture Coated Aluminum Coil they need for their projects, whether large or small.

Hot Products