Fiber Cement Board 1200*2400mm Fiber Cement Board 1200*2400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

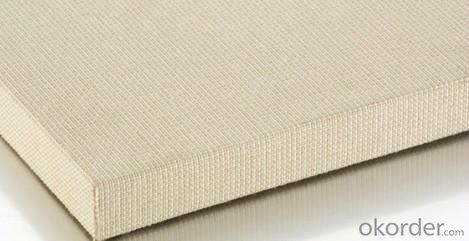

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: The tile guy that I am using has never worked with stone, so I am worried. Can you please give me some insight on some things I should know about using stone (slate) for wall tile in a shower/bath.

- You would use cement grout. If its in your house, i would consider then laquering it to make it nice and shiny and stop water sitting in cracks and creating mould.

- Q: Cement pressure plate to do the bathroom partition, strength and humidity can meet the requirements?

- Cement pressure plate can be used in the bathroom to do the thickness of the partition in the 30-50 mm cement pressure plate is used to tile.

- Q: I want to remove and replace my laminate covered counter tops, the particle board underneath is chipping bad near some edges,and there's almost no good place to put screws in to hold the dishwasher. I need plans or instructions how to build a replacement so I can use plywood and cement board to install ceramic tiles. How do I frame it for the sink and the edges?

- ok.. first things first..what size tile are you laying.. what type of facing..bullnose, cut tile that matches the top .. the type of edging you use will determine the depth of the top ( thickness) be sure that the edging wont interfere with the doors or drawerheads..i would also recomend epoxy grout..a little more money and trickier to apply but worth it in the long run. i would completely remove the old countertop..determine thickness of the new top and purchase materials. ncrete board comes in two thicknesses 1/2 and 1/4.. buy plywood to make up the diff..remember to stagger any seams for strengh..screw down the ply either from the top or from underneath through cabinet gussetts...then screw down concrete board..dont skimp on screws.. use thin set and tape edge pieces for 24 hours then grout!..take your time in initial layout as this could save hours and money..the answers about the sink looked good..would add to center the sink in the sink base cabinet though and check for fit before installing any tile

- Q: Application of cement pressure plate

- Cement pressure board can be used for external wall insulation, wall partition, sound-absorbing ceiling, interior decoration

- Q: We have drywall in our kitchen that was painted with a smooth semi-gloss paint a good 8 yrs ago. We'd like to install 3x6 tumbled marble as a backsplash over the drywall. It's about 1/4 thick so probably slightly heavier than say, the tiny square glass tiles that come on a 12x12 netting. One person at the Home Depot said we could just sand and scrape up the drywall and then apply the thinset and install the marble. Another said we might want to use a cement backing. We aren't really DIYers and would so we don't want to create extra work with the cement backing if it isn't needed. That said, we don't want the drywall to start peeling and the marble tiles to start falling off after a short amount of time. Please advise. Thank you!

- ild install a 1/4' hardyboard board first -the thinset will not last sticking the tiles to the paint

- Q: Its all gonna get covered with mortar anyway when I put the tile on, right? So.... Is it NECESSARY to mortar the joints before hand or not?

- Nothing is necessary of you don't care about water damage. If you care about doing a good quality job that insures that the area is watertight then mud the joints. Remember that water is the worst enemy of a house next to termites. You would be surprised to see what a hairline crack can do to the structure of a house. Not to mention the mold and the insurability of a home. Water damage on an insurance record is shared on a national database of insurers and when its there, good luck every getting insurance.

- Q: how do those karate guys break cement and wood pieces by jsut like one hit, why doesnt it hurtthem or break there hands and feet?dont gimme a BS answer,im lookin for an actual reasonable explanation

- wood is easy to break against the grain. Cement requires you to spend lots of time conditioning you knuckles so you don't break them but it is possible for anyone with spare time to condition to break cement and bricks(some people start with ceiling tile). How ever there are masters in Japan that can punch a tree full strength with out breaking knuckles and master in Korea that can break Marble and i believe there is one that punched a ox and it died

- Q: how can I cut the cement backer board for tiles?knife? saw? (what blade?)

- For thinner backer board(under 1/2), use a utility knife. Score one side and then tap it from the back at the cut. For backer board over 1/2 it is best to use a Skill saw or a Jig saw. If you need to cut a hole, for around a toilet or something, drill a hole in the center of the area and then cut it out with a Jig saw. Pretty much any old saw blade will work fine, it cuts very easily and does make a bit of a mess. It's a good idea to use an adhesive (Liquid Nail) or thinset mortar underneath the backer board as well as screws/nails for the best job. Good luck with your project

- Q: This is a 1950s sink.

- sure its superb to get rid of each thing however the cement board is 3/8 to a million/2 in. thick and the tile being placed on it truly is a pair of a million/4 to 3/8 counting on the quantity of thin set used. are you able to place a threshold down on the doorway to house for this distinction in top? And if the timber below the tile floor isn't a minimum of a million in. thick then the flexing of the floor will continually reason cracking of the grout lines if no longer the tiles them self. those are a pair issues people forget whilst wanting a tile floor. good success

- Q: How much is the square of the cement board

- With the development of China's modernization drive, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old building renovation, interior decoration, roof and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on. I hope that my reply is helpful.

Send your message to us

Fiber Cement Board 1200*2400mm Fiber Cement Board 1200*2400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords