Customized Fiber Cement Board / External Wall Board / Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

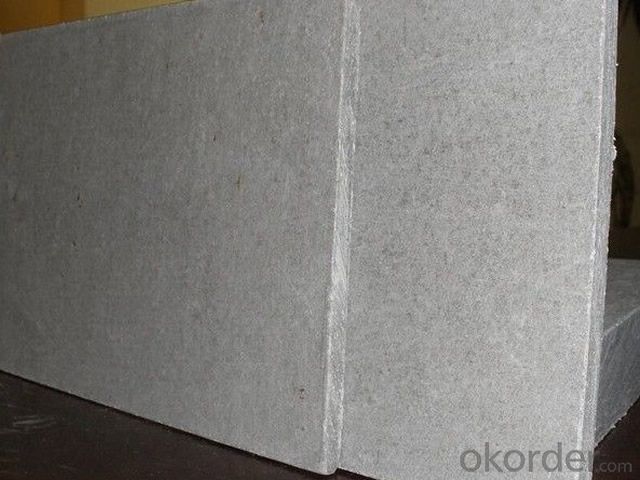

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

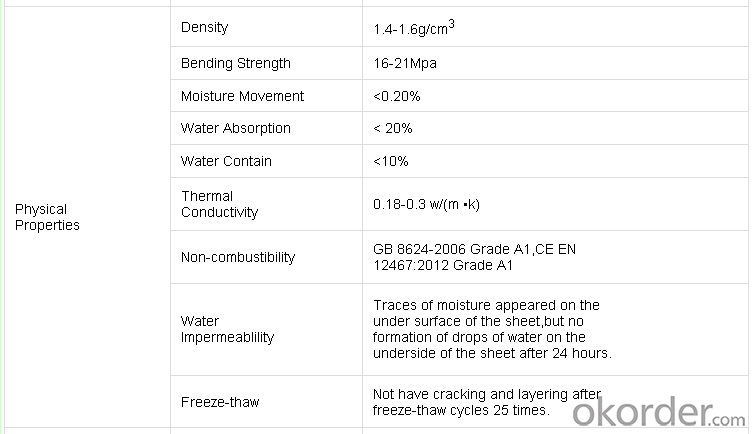

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q: I am in the process of purchasing a townhome and I am looking to tear up the existing 12 ceramic tile that covers the entire main level... an area close to 600 sq. ft. to make way for laminate flooring. Thinset has been used to bond the tile to the cement backer board, and the backer board has been screwed to the wooden subfloor. There is also some sort of adhesive/mortar bonding the cement board to the wooden subfloor. What tools will I need. Are there any techniques that would make it easier? Would trying to remove the cement board damage the subfloor? If so, would it be acceptable to repair damage with some sort of floor leveling compound?

- big *** crow bar, thats how i did my kitchen, yep it sucks. you can get a nice one for this in the garden section its made for digging holes but has a nice flat section, for what I dont know but it teats a floor up,

- Q: Can veneer cement board be on the floor?

- VIVA wood cement board is environmentally friendly green building materials, from cement as a cross-linking agent, wood as a fiber reinforced material, adding part of the additives made of pressed sheet, mainly by the crushed wood chips and Portland cement glued together, the color Clean, double smooth and smooth. The product combines the strength of wood, ease of processing and cement durable characteristics. Wood fiber cement board in the 40's began to be widely used in Europe, has now become a wide range of international application of building materials. It is versatile, excellent performance, with corrosion resistance, heat resistance, resistance to corrosion, easy processing, and cement, lime, gypsum with good, green and other advantages.

- Q: FC sound-absorbing board is what material

- FC board is made of pressurized fiber cement board as panel, with sandwich material in the factory processing production of composite wall panels.

- Q: Hi everybody! I just installed hardibacker boards in my bathroom. But I had to remove 1 pc 'coz I made a mistake. Can I still use it again? I screwed it every 8 inches around the edges and along every stud. Can I just cover the holes with thinset? Thanks!

- Yes, as long as you adequately fill the holes, you're good to go

- Q: How to fix the cracks in the ceiling

- In the cast-in-place concrete slab cracks at the cracks will be 15cm wide surface layer to wear, and clean up, after the use of carbon fiber special glue will be 10cm wide carbon fiber ride stitch paste, and other plastic dry putty scraping;

- Q: Can anyone suggest a good way to cut small pieces (i.e. 2-4) of Hardiebacker and make it break cleanly? I can't seem to get it to break off easily unless it's bigger piece... and I was told not to use a power tool (i.e. circular saw) as it would create a ton of dust, which could be bad to breath in.

- Wet backer board as you cut it..keep water away from electrical components of saw. Dust will no be minimal.....this is a 2 man job.

- Q: Gypsm plaster is recommended in Christopher Alexander's Pattern Language (#235 Soft Inside Walls) If I were to go to a building supply store and ask for gypsum plaster would they know what I was talking about? ...Is it a universal term? Can you give me a chemical formula?

- Gypsm is hydradated pulverized limestone. You would ask for Gypsym topcoat or Gypsm tape adhesive in the Drywall department of Lowes. It costs today $9.95 for a 5 gallon pail of the stuff. Gypsm is resoluable in water after drying. In other words you can redissolve gypsm in water. Gypsm is mined in the US in states like Michigan, Indiana, Ohio and so on. It is a naturally occuring substance. Plaster of Paris is unhydrated form of lime. When wetted with water it changes chemically and remains hard no matter if submerged into water. The process is irreversible. Cement is made from clay and limestone fired to high temperatures, then ground and pulverized. When water is added to cement it changes its chemistry and the water reacts with cement forming a new compound It is irreversible The Romans invented Cement. Common Drywall is gypsm between 2 layers of paper enclosure. There are also metal lath in 26x84 inch lenghts and plaster board lath in 16x36 inch lengths Those all above are nailed or glued to the house studs.

- Q: Can the cement board cut off the wall directly

- Due to the cement board surface is too smooth, not with the putty layer (or sand layer) very good bonding, the need to increase a layer of wire mesh to increase the degree of sewing. Need to first barbed wire fixed on the wall, and then sandy gray leveling; until the sand ash dry, then putty putty, paint.

- Q: do I need to put down a vapor barrier or cement board or can the hardwood be glued down and the tiles with thinset? Also what type grout should I use on floor and wall tiles?

- Porcelain or clay tiles can be glued directly on concrete. For hardwood, I suggest a floating floor over a vapor barrier.

Send your message to us

Customized Fiber Cement Board / External Wall Board / Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords