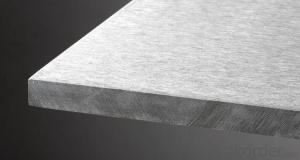

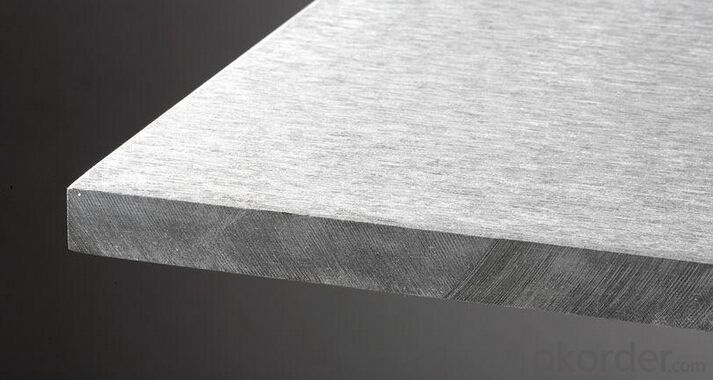

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives.

It is 100% free from asbestos, sepiolite, inorganic fibres or formaldehyde.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

Images:

- Q: How to open the cement board

- Punch with a drill or a core. 1), small points of the hole, less than 30mm use the impact drill, see how much you play the hole, there are large and small impact drill, there are different diameter drill. 2), relatively large 50mm or so to use the core machine, according to the size of a variety of sizes and depth of the core machine.

- Q: do you have to tape cement board before tiling?

- you dont have to but the idea is to fill and fiberglass tape the seams keeping them ridged so that in years to come the grout doesnt crack out. Yet thats something rather new, you should be fine just filling any of the voids with mastic adhesive as you lay them. A portland cement mix works well on durarock, and the new backer board, though drywall quickset works just as well.

- Q: I have a small bathroom approximately 4'x8' and I laid down and screwed in cement backer board. However, in my attention to detail I neglected to put down thin-set mortar underneath prior to screwing and taping down the board. I tried to pull the cement board up but I cant get under the tape that I mortared down to get to the screws. Am I in trouble here or can I go ahead and skip that and continue to tile? Please help...

- OK... You didn't specify whether you're doing a floor tile job or a wall tile job. If doing a floor tile job, here is the procedure: You can (but don't have to) apply thin set directly to the plywood and then lay and screw down the cement backer board onto the wet thinset. If your floors are pretty firm already, you don't even need to put the thin set on the plywood. Just screw the cement backer board onto the plywood. The thinset makers tell you to put thinset between the plywood and the backer board just to sell more product. It's an unnecessary step if your floors are already pretty stiff. Make sure you screw the backer board down and hit the floor joists underneath with the screws. Screws only going into the plywood is not sufficient. All screws must enter the joists, so get those marked before you start. Use thinset with a notched trowel on top of the backer board to lay the tile into.

- Q: I want to remove and replace my laminate covered counter tops, the particle board underneath is chipping bad near some edges,and there's almost no good place to put screws in to hold the dishwasher. I need plans or instructions how to build a replacement so I can use plywood and cement board to install ceramic tiles. How do I frame it for the sink and the edges?

- 1. first you screw 3/4 inch laminated plywood to the base 2. install 3/8 inch backer board with one inch screws 3. ceramic tile over the backer board 4. be sure to pay attention to what type of back splash you are going to use

- Q: How to solve the old concrete and the new pouring between the concrete does not leak it?

- This expansion of 50 * 100cm concrete floor, the first is to ensure the safety of the structure, need to consider the wall load and the floor will bear the live load, there is no high stiffness of several I-beam or angle as a beam, feel unsafe. It is recommended to install three beams, concrete inside can not use steel. Wall holes do not need too much, with mortar fixed I-beam or angle steel, mortar hardening for three days after the follow-up operation.

- Q: Installing a shower in my basement, and am framing around a fiberglass 36 square shower base. should I put it flush against the frame and then attach cement board (it will overhang) or leave room to slide cement board between base and frame? Thanks!

- I saw another answer that tells you to leave it above the flange of the base, but here is the problem with that and how I do it. If you leave it short of the base, there is now a gap however high the flange is with nothing to support the tile OR a place for the grout the sit because there is a void behind the tile. What I do is measure the thickness of the base ( usually 1/4) and then I rip a filler strip the same thickness as the flange. I nail it to the studs from the flange up to where you are going to stop the backer board or to the ceiling and then attach Hardibacker or Wonderboard to the furred out studs. Now the substrate can be installed 1/4 inch off the bottom of the base unit to avoid water wicking up and the tile has a full backing to within 1/4 of the base as well as the grout goes all the way in instead of sitting only BETWEEN the tiles as it would if you left it 1 1/2 up off the bottom sitting on the top of the flange. The only adjustment you will need to do is set the shower valve out whatever the thickness of the furring strips you add so it finishes on the tile surface to the manufacturers specs.

- Q: How to do the effect of water

- Wood, cement, and mineralized sawdust, with some water and fire resistance. The surface of the irregular lines, which is the most unique material .Compared by the designer's esteem, but the price is high in the 150 / level or so, but compared with other materials is still very unique, of course, can also be used Other cement board to replace, in general, the difference is still great.

- Q: I have a friend who owns a house who believes it was built in 1968. The basement is in immaculate condition-- completely dry. The walls are poured cement and you can see where the forms were taken off the wall after it was poured. My question -- did they pour walls back in 1968 or was cinder block the building material used? I think the house was renovated within the last 15 years. My friend and I are baffled. Thanks!

- Glue is not going to work for you... You should put a vapour barrier down first (under the bottom plate). This can be 'Sill gasket' (which is foam on a roll about 6 wide...) or tar paper or even just 6 mil plastic. This will prevent the bottom plate from 'drawing moisture' through the concrete. Usually a basement floor is only a few inches (at best) deep of concrete and then there's stone and dirt below that. Moisture will pass through concrete over time and if the conditions are right, mould will grow in a few years... in your bottom plate and lower studs. I always use tar paper, set the position of the bottom plate, drill with a concrete bit and then use a hammer-in type anchor... These anchors work like a pin driven down through a hollow shaft that expands. You drill right through the bottom plate and the floor, set one of these in the top of the board and whack it with a hammer to pound the pin into the hollow shaft that you stuck in the hole in the wood... works awesome, easier and cheaper than tapcons and really strong at one every 16 or so (between the vertical studs). Home Depot has them by the box in different sizes... Good Luck!

- Q: I came into many buckets of GAF TOPCOAT liquid which says it can be sprayed onto a roof or rolled on. I've only found one other idea for the walls in my wet room/shower area which is flexcement that is waterproof. Is it a good idea to try this or not. Really don't want to mess it up after putting much money into the walls as is. Here is the site that describes the product.

- bad idea. you are writing about a roofing material and your cement board already is the right material to use. topcoat means just that. is the GAF product to be the finish of your bath? course not!

- Q: I need to raise a bathroom floor about 3/4 inch. I have already poured a thin layer of self leveling concrete over what appeared to be some sort of concrete floor that had some uneven areas (60 year old house). I have read about how you are not supposed to put backer board on concrete because you can't secure it. My question is this: could you lay the backer board on top of the SLC, leave some small gaps between the boards, and then pour another layer of SLC on top of the backer board, thereby cementing it into place??

- I d rather see you pore a SLC to the depth you need it.. Some compounds you can pore to the depth of 1 in 1 pore and some you need to do in 2 pores. Now if you need to do a full 3/4 depth you can do a tile mud bed , but this is a little challenging for a 1 st time. If you have some good DIY skills then you can probably do it. Just going over slab requires a few different steps when doing a mud bed over slab. Any questions you can e mail me through my avatar and check my qualifications there. GL

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords