Waterproof Calcium Silicate Board Tiles Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

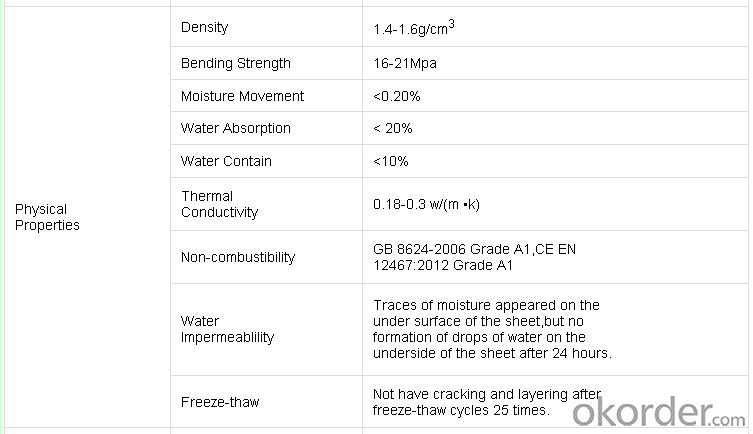

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

Main Product Features:

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: We're tiling our basement. The floor is plain concrete. Do I need to put a layer of plywood, then a layer of cement board, then the tiles, or do I just need a layer of cement board then the tiles?

- you should be able to tile right onto your concrete pad. That's how my saltillo tile is placed in my kitchen, be sure to seal the grout as soon as it is fully dry. GOOD LUCK

- Q: Attic with a channel steel structure, covered with aluminum instead of wood multilayer? Is it feasible?

- Home decoration to do the attic, channel structure, decoration master said just just to shop a layer of 1.8cm wooden multilayer board and then shop the floor, multi-layer board formaldehyde exceeded, want to replace the wood multilayer 5mm aluminum.

- Q: I want to put a cork bulletin board outside my store but it's a cement wall and I do not want to ruin the cement wall.

- I tapped some nails in. But I don't recommend it. It took a long time and you'll probably get charged for the damage it does to the paint. I found some sticky, puffy stuff from Duct Tape. It's double sided and it's waaaay sticky. For my heavier stuff I just doubled/tripled up and it hung right up. This is what I did for my full length mirror. Also they make those clear plastic holder things. I'm sorry, I'm not sure what they're called. But they have sticky on one side and you stick that to the wall and then there is a hook on the other side. They work great too and are cheap!

- Q: how do I lay cement board on a concrete floor with out screws?

- If the concrete floor is smooth, you can place the tiles on the concrete. The thinset will do the job. If the concrete is rough, try concrete refinisher. It's easy to use and will give a smooth surface. Hardi backer or cement board should be screwed to the floor. Use a masonry bit to drill the holes. Be sure to tape the seams and then proceed with your tile. Using a high speed drill will drill the holes quickly and easily. I do this for a living.

- Q: The floor is on a raised foundation and we were told that there are 2 options: float it on thin set or use a concrete back board. Is there any perference to one over the other? I don't want the tile to crack.

- These answer are old there are at least three different kind of boards you can lay down instead of cement board they are lighter less expensive. Check with your local Lowes or Home depot they carry them and tell you which one is best for what you are laying, there is a big difference from slate and granite and just plain old ceramic tile

- Q: Just put cement type 1 portland,over hardie board about 3/8 of an in. how long do i have to wait to stain it?

- i would give it a week, it should set pretty quick...

- Q: Wood keel cement pressure plate partition wall tiles

- Before the tiles, the cement board should first use the interface agent to brush, then paint a layer of 1 cm or so of cement mortar, the label is appropriate high; 24 hours after the water to do maintenance (to prevent the paint layer too dry), 48 hours After the tile can be posted (at this time the strength of the paint layer has not yet reached, when the tile can not be applied to hit the force); tiles must be fully soaked.

- Q: I can jump atleast 4 or 5 inches on a rug,grass, mud, sand. but i cant on cement when i ollie on cement my board like slips away after i pop and on everything else it doesnt. help?

- that's rather helpful to benefit the grip on your board. If no longer that then perchance your shoes are the issue. If no longer the two of those merely regulate the way your foot is on the board, and prepare prepare prepare

- Q: FC fiber cement plate can be affixed to the aluminum plate?

- FC fiber cement pressure plate can be affixed with aluminum-plastic plate, but use glass adhesive paste.

- Q: A grade fireproof material cement board

- High fire resistance NK-YB01 composite foam cement board is an inorganic material, is a Class A fireproof material, which has a good fire resistance, refractoriness of 1000 ℃ or more, fully meet the external wall insulation requirements.

Send your message to us

Waterproof Calcium Silicate Board Tiles Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords