Silicate Board Tiles Waterproof Calcium

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

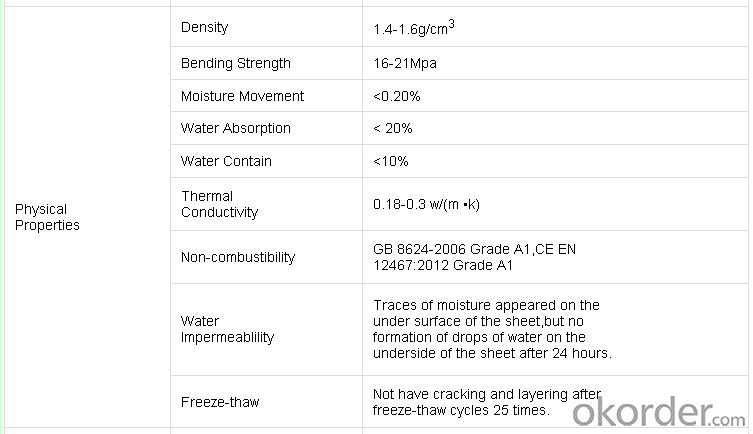

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

Images:

- Q:How much should the keel spacing of the dry wall fiber cement board?

- The modulus of the general country is 600 * 600 or 600 * 800mm External wall dry hanging must choose high-density fiber cement board

- Q:Advantages and Disadvantages of Foaming Cement Thermal Insulation Board

- According to the different production methods can be divided into physical foam insulation board and chemical foam insulation board.

- Q:I've already got the cement board down, taking it back up would mean messing with the toilet flange, which means plumbing, and that sucks. Plywood was in pretty good condition. Thanks in advance!

- If you don't apply mortar, the tile will shift around, come up, etc. It's best to go ahead and do it right when you are initially laying it therefore saving yourself a costlier repair. Good luck.

- Q:Clothes on the stick asbestos fiber how to do

- If you have asbestos fiber, you can use a transparent tape sticky, can effectively remove fiber impurities, the effect is very good, easy

- Q:i'm going to be putting in durock in my shower? what kind of screws do i use? do they have cement board screws?

- Anodized drywall screws

- Q:Hi, I have an outside breezeway that connects from my house to my garage with a roof and cement slab. I'm in the process of closing it in and making it part of my house(fully heated). I'm going to tile the floor but I'm not going to have a sub floor to insulate under it, I worry about moisture, cold floor and cracking of tiles (I live in Michigan).So my question is I'm not sure on how to go about this, I was thinking a 1/4 to 3/8 insulation rolled on the slab, then cement board and then thermostat controlled heating mat then tile, What do you think, thanks.

- I agree with William, use a rigid insulation rather than a roll insulation. It would be pretty much impervious to moisture. A roll insulation would eventually hold any moisture and get moldy and lose any r-value.

- Q:Outdoor doors of the aluminum-plastic plate can be directly in the waterproof cement board paste it?

- can. But when the aluminum-plastic plate, then a long time will be knocked up. After all, the wind and sun is just a matter of glue

- Q:Is it required to waterproof a basement shower when it sits directly on the cement floor? Can we use cement board on the curb or is it required to use mortor and build it that way?? Can be lay the floor tile directly to the cement floor? Any suggestions will be great?? Thanks

- Crosst put you on right track. ADA accessible showers have no pan which would limit handicapped access. Walk in showers are fairly common even for non handicapped use , but are as large to contain spray if there is no door planned. Have seen tile set on concrete deck on new construction in healthcare facilities where the floor tile was run directly into the shower enclosure with no lip at all at entrance. Guessing ,but they probably achieved pitch by varying thickness of skim coat & thinset tile cement. Hope that helps also

- Q:A grade fireproof material cement board

- High heat insulation NK-YB01 composite foam cement board closed porosity> 95%, high porosity so that the air flow caused by low heat transfer, is a prerequisite for high insulation. Therefore, the thermal conductivity of the external wall insulation board is (0.045-0.068) W / m.k, and the thermal conductivity of the polystyrene board is slightly lower, but the actual effect in the actual engineering is basically the same, which can meet the needs of building insulation and insulation.

- Q:Can cement board be used for floor decoration?

- A floor of the ground used: 1. tiles 2. flooring 3. marble you asked the shop where the shop shop black stone was here I tell you about my decoration experience, the store floor decoration generally use ordinary rows of tiles, The reason is: all ceramic tiles and marble cost is expensive, the general owner will not use

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicate Board Tiles Waterproof Calcium

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords