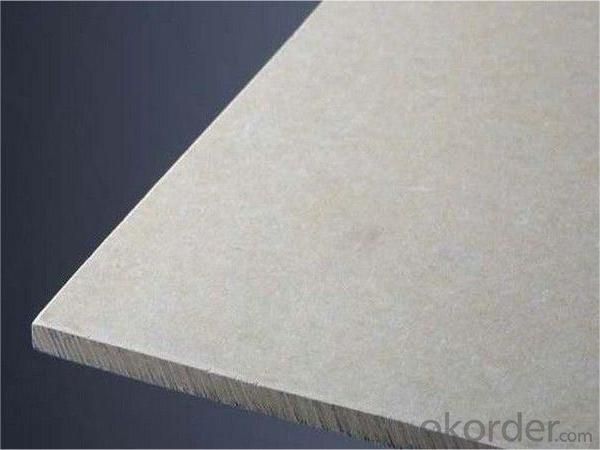

Waterproof Calcium Silicate Board Tiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

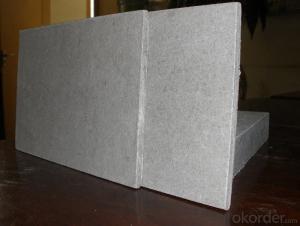

Raw materials: pure quartz powder, quicklime, calcium silicate, plant fiber, and various fine mineral fillers including dispersants and additives, are formed into a wet sheet and then processed through high temperature and high pressure autoclaving for more than 10 hours using advanced technology. This process creates a special calcium silicate board. There are no asbestos, brucite, or meerschaum in the raw materials or formulations at all.

Product Applications:

1.Industrial and residential ceilings.

2.Industrial and residential partitions.

3.Ceilings and partitions for bathrooms and wet areas.

4.Base boards for operating rooms, clean rooms, and labs.

5.Fireproof boards for air passages.

6.Furniture and accessories.

Product Advantages:

1.Excellent fire-proof

2.Excellent damp-proof

3.Durability and long service life

4.High strength

5.Stable dimensions

6.Good heat and sound insulation

7.Non-asbestos

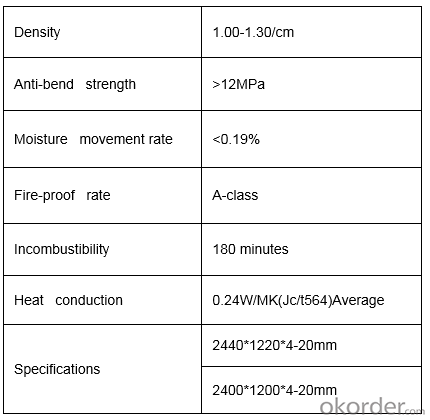

Main Product Features:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Calcium silicate board ceiling, wall patchwork and vertical degree how to control?

- If the tile is affixed to the top of the case, on the side of the wall from the ground 230-240cm high point, with a transparent water pipe fixed on the other side of the wall coincide point and then line, to determine the hole after drilling with diamond drill bit The

- Q: The difference between calcium silicate board and plywood

- The use of a long time there are drums, brittle, yellowing, cracking problems, in a fire is not, although it may add fire agent compound, but in high temperature will release toxic gases, so the safety performance is not good, and calcium silicate Board is completely inorganic and wood fiber (asbestos fiber now many manufacturers have no use, radiation) composite, high strength easy processing, life and building life is equal, strong fire resistance, the maximum fire temperature of 1050 degrees.

- Q: Where to produce 3 m long reinforced fiber calcium silicate board

- Calcium silicate board and fiber reinforced calcium silicate board is the same concept, the density from 0.85 to 1.5 range, mainly depends on customer requirements and production process. 1 what is called low-density calcium silicate board. Thickness and density is not related, however, in general, low-density calcium silicate board are relatively thick, generally more than 12mm. Because of the low density, calcium silicate.

- Q: Calcium silicate board outside the brush coating needs grassroots?

- Now the market in Hebei, Beijing, Fujian and other miscellaneous board quality is not stable enough, the process does not pay attention to the above questions must be out. In particular, the batch of a few putty, a putty dry to do the next one, putty thickness can not be too thick, 2-3MM can, and some workers do not understand, plus buy a cheap board after the installation of wave deformation, putty approved Die thick (cracked place with shovel shovel actually have 6-8MM thick), not cracked strange. As for the paint on the normal to do like a bottom two or two bottom side, do not worry. The most important is the grassroots must be installed and installed.

- Q: Calcium silicate board how to deal with smooth surface, that is, I would like to foil in the calcium silicate board, is to be very common to paste the bottom,

- Directly to the skin more trouble, the domestic I have not seen which business to do so, foreign Japan to do a lot, especially calcium silicate anti-static floor, are PVC or melamine paper paste. There are ways to do, you can find some floor or furniture to do a small factory, OEM can do small batch, the surface do putty layer and then sanding to the need for smoothness, and then paste the skin like, the effect is the same The

- Q: Is the screw in the calcium silicate plate spin reliable?

- Unreliable. Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose fibers as a reinforcing material, calcium-siliceous material as the main cementing material, by pulping, billet and high pressure steaming and other processes and made.

- Q: Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- There are dust, waste gas, waste water pollution, calcium silicate board used lime, cement, quartz powder, chrysotile asbestos (carcinogens, most domestic enterprises are still used) and other raw materials, in the feeding, finished sanding, cutting process , Many companies ignore the dust pollution, dust removal capacity and capacity does not match, asbestos,

- Q: Calcium silicate board surface putty Why crack?

- First, the first clean seams at the end of the dust, after cleaning, in the seams sweep a white latex, can achieve better anti-cracking effect. (Figure 1) Second, with a scraper putty putty evenly embedded in the seam mouth. (Figure 2) Three, and then immediately wiped the self-adhesive fiber mesh belt, and the net completely affixed to the putty, and then a layer of putty on the net belt putty. (Figure 3) Fourth, in order to further strengthen the anti-cracking effect, to be a putty completely dry (about 5 hours, the case of wet weather will increase), with a putty in the thin layer (slightly wider than the seam chamfering area and slightly higher On the board) (Figure 4) Five, until the putty completely dry, with sandpaper on the surface of the caulking, sanding, so that the entire board smooth.

- Q: Is it harmful to calcium carbonate on home improvement?

- Calcium silicate board consists of a variety of organic and inorganic substances, the use of advanced program-controlled equipment and flow slurry process production molding, high temperature autoclaved curing and special technology processing, is an environmentally friendly, safe, multi-functional high-level building With the plate. Product composition High-purity quartz sand + mica + perlite and other mineral fillers + plant fiber + moderate amount of low-alkali cement

- Q: Calcium silicate board can be used on the external walls, waterproof crack?

- Calcium silicate board is less to do outside the wall panels, are generally decorated with interior walls The main reason is its advantages: light, moisture-proof performance is good, easy to change color, high hardness, good sound insulation performance. The calcium silicate board also has obvious shortcomings: the installation is not easy to replace, the installation of the use of iron keel, the price is more expensive and easy to break, slit. But now there are external walls with calcium silicate board, but from the cost point of view, the proposed external walls or do not use calcium silicate board

Send your message to us

Waterproof Calcium Silicate Board Tiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords