Non Asbestos Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

Calcium Silicate Board is mainly made of siliceous and calcareous materials

as major and natural cellulose reinforced, forming in Hatschek process and high

pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages

ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption ,

no distortion and no radiation Used assuspended ceiling, partition, heat insulating board,

base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines,

prefabricated structures, door shutters

2,Main Features of the (Calcium Silicate Boards)

Application: partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations;

interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Moisture:<10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate:<0.19% (GB/T7019-1997)

Product Description

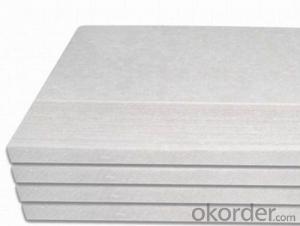

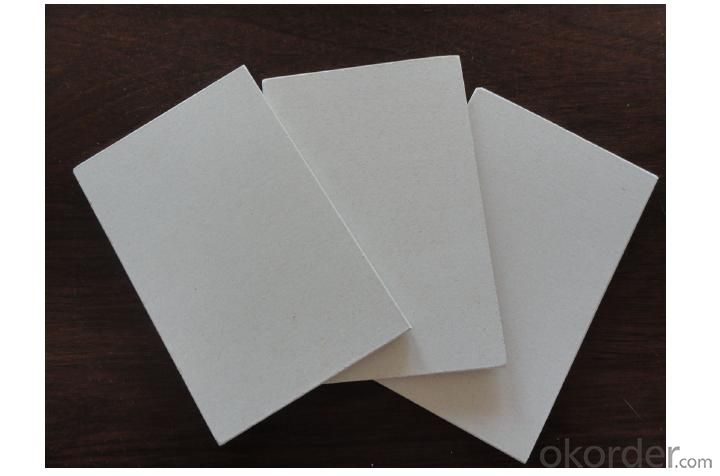

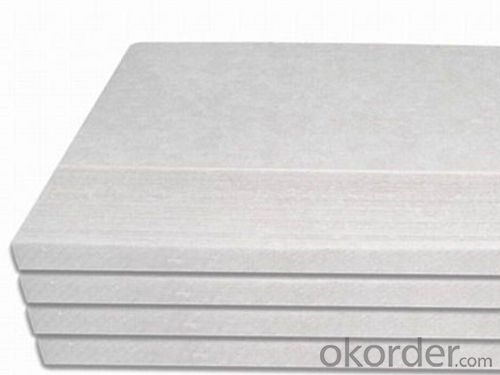

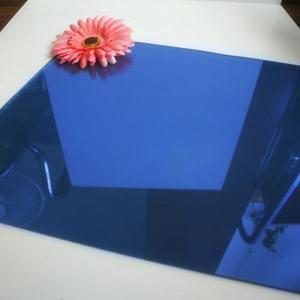

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Size & Loading Quantity of Calcium Silicate Board:

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS /

| Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS /

| Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS /

| Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS /

| Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS /

| Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS /

| Single, double surface Sanding or tapered |

| 15mm | 1200mm x 2400mm 1220mm x 2440mm | 346 PCS /

| Single, double surface Sanding or tapered |

| 18mm | 1200mm x 2400mm 1220mm x 2440mm | 294 PCS /

| Single, double surface Sanding or tapered |

| 20mm | 1200mm x 2400mm 1220mm x 2440mm | 260 PCS /

| Single, double surface Sanding or tapered |

Customized sizes and thickness are also produced.

5,FAQ of (Calcium Silicate Boards)

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

- Q:Calcium silicate board water absorption on the performance of the plate have any effect

- Calcium silicate board if the water after the impact of the plate have a certain impact, but will not loose will not be deformed, and then back to the plate after the original strength will be restored

- Q:What is the new environment of environmental protection wall insulation materials

- Now more and more serious environmental problems, "environmental" in the past may be just a slogan, and now really have to face a problem. In today's low-carbon, environmentally friendly environment, building materials market surging,

- Q:Is the perforated calcium silicate wallboard used in wall decoration?

- Perforated calcium silicate wallboard as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, in the practical use of a wide range of applications.

- Q:Calcium silicate board ceiling, wall patchwork and vertical degree how to control?

- If the height of the ceiling can be used to determine the height of the tile, you can use the wood is 3cm thickness * wall length, with steel nails to fix the wood on the wall above the tile, according to the determined installation height on the wood with ink bucket Horizontal Line Installation Edge. I hope I can help you

- Q:Calcium silicate board can do office space wall decoration it?

- It is best to use gypsum board. Calcium silicate board construction trouble, mainly the gap is not handled well cracked, drill holes can be on the screw no paper gypsum board good on the screw so rarely used to do home improvement.

- Q:Ceiling, shape the same, with gypsum board is good, or with silicon calcium board material is good

- Silicon calcium board with a better material, the price is indeed more expensive than gypsum board. But you are also home decoration is not how much, cost-effective considerations. Calcium silicate board and cement board are two different materials. Hope my answer can help you!

- Q:Calcium silicate board and noise board which sound insulation effect is good

- Sound insulation board is a collectively, there are different materials of sound insulation board, such as rubber, plastic, cement, PVC, metal and so on. So there is no way to directly determine the "calcium silicate board and noise board which sound insulation effect."

- Q:Glass magnesium board VS calcium silicate board who can be better

- Glass magnesium board is made of magnesium oxide, magnesium chloride, water ternary system is modified by the configuration, because of its A-class fire, water and moisture, while green, in line with the characteristics of sustainable development, by the state recommended.

- Q:Calcium silicate board above the watermark is how to cause

- Yellow whirring, and generally the reasons for the use of kraft paper fiber, dry after generally not anti-color, but I suggest you use sanded calcium silicate board, such problems will be less.

- Q:Calcium silicate board surface smooth it? Waterproof? Can I use this board to do the outdoor door?

- Calcium silicate board is the biggest characteristic of waterproof fire, stable performance. Using the calcium silicate board to do the outdoor door is already a mature technology

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non Asbestos Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords