Moisture Resistant Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

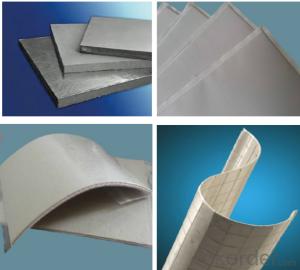

1. Basic Sizes of Moisture Resistant Particle Board

1)Size: 1220x2440x(9~25)mm

2)Material: poplar

3)Density: 700kg/m3

4)Glue: E0, E1 or E2

2. Specification of Moisture Resistant Particle Board

|

Product Name |

Moisture resistant plain particle board/raw particle board(chipboard/flakeboard/shaving board) | ||

|

Size |

1220x2440mm or as clients requirement | ||

|

Thickness |

9~25mm | ||

|

Thickness Tolerance |

+/-0.2mm | ||

|

Surface Treatment |

Sanded or pressed | ||

|

Material |

Wood chips (poplar or combi) | ||

|

Glue |

E0, E1 or E2 | ||

|

Grade |

A grade or as clients requirement | ||

|

Density |

700~720kg/m3 | ||

|

Technical Parameters |

Moisture Content |

≤8% | |

|

Water Absorption |

≤10% | ||

|

Modulus of Elasticity |

≥2800Mpa | ||

|

Static Bending Strength |

≥25Mpa | ||

|

Surface Bonding Strength |

≥1.50Mpa | ||

|

Internal Bonding Strength |

≥0.80Mpa | ||

|

Screw Holding Ability |

Face |

≥1500N | |

|

Edge |

≥950N | ||

|

Usage & Performance |

Plain particle board is widely used for furniture and interior decoration. With good properties, such as, easy fabricability, high bending strength, strong screw holding ability, heat resistant, anti-static, long-lasting and no seasonal effect. | ||

|

Packing |

Loose packing | ||

|

Standard export pallet packing | |||

|

MOQ |

1x20’ FCL | ||

|

Supply Ability |

5000cbm/month | ||

|

Payment Terms |

T/T or L/C at sight | ||

|

Delivery Time |

Within 15 days after receiving deposit or original L/C at sight | ||

|

Certification |

ISO9001:2000, CE, CARB | ||

- Q: According to the surface conditions:

- According to the water resistance of indoor water-resistant and outdoor water-resistant class

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: The environmental performance of particleboard

- As the particleboard production process, the general use of formaldehyde-based adhesives, so its finished product will release more or less free formaldehyde

- Q: Make the raw material of the particleboard

- Can be pre-pressure and hot-pressing treatment. Preload pressure of 0.2 to 2 MPa, with a flat press or roller press.

- Q: Particleboard in the production process of environmental performance

- . First of all, the unused particle board piled in a small house, close the doors and windows

- Q: What is the production process of particleboard

- the plate thickness deviation and the degree of material transfer between the shavings

- Q: What types of particleboard can be divided into?

- bending strength, vertical plate tensile strength (internal strength), grip nail force elasticity Modulus and modulus, etc

- Q: According to the use of points: Class A particleboard; Class B particleboard

- gradient structure particleboard; oriented particle board; waffle particle board; molded particleboard.

- Q: How to improve the particleboard market space

- we must improve the scale of the project construction, the small particleboard factory to reorganize the small particleboard factory in order to improve the quality of the particleboard and reduce the cost and improve the research and development

- Q: The product structure of the wood-based panel industry

- China's wood-based panel industry product structure is not reasonable, difficult to adapt to market demand.

Send your message to us

Moisture Resistant Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords