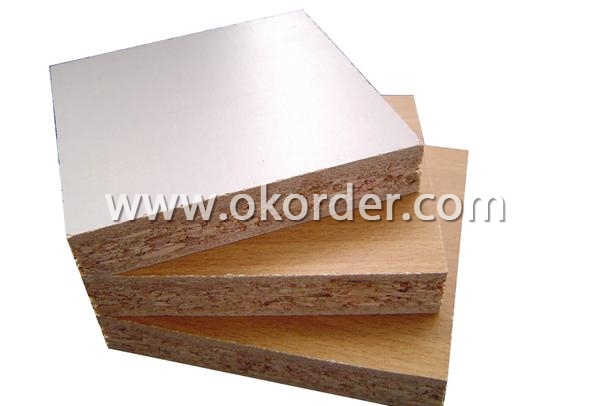

E1 Melamine Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Basic Specificaiton of Melamin Faced Partical Board

|

Plain / Poplar Particle board | |

|

Size |

1220*2440; |

|

Thickness |

2.5mm,5mm,6mm,8.0mm,9.0mm,12mm,14mm,15mm,16mm,18mm,22mm,25mm or as your request |

|

Material |

Poplar or pine |

|

Surface |

Melamine(Solid color or woodgrain),veneer,PVC |

|

Color |

Any color |

|

Glue |

E0,E1,E2,MR |

|

MOQ |

21cbm |

|

Density |

650-700kg/m3 |

|

expansion rate : |

8%-10% |

|

Features |

moisture-proof,good nailing strength,suitable for wardrobe making |

2. Products Charateristics

(1)Density:tolerance+/-2%

(2)Moisture-proff,low formaldehyde emissions,fast curing ,high tack

(3)mixed hardwood,poplar,pine or Eucalytus

(4)Good for different climatic conditions

(5)Function:making furniture,doors and windows and floor and kitchen cabinet,e.g.

(6)we have about more than 200 colors for your choice

3. Look forward to your inquiry.

We persevere in the management of credit and innovation,and we are

willing to cooperate with all the friends for mutual development. looking

forward to your inquiry and trail order.

- Q: What create an excellent condition.

- therefore, in recent years, China's demand for particleboard is increasing year by year

- Q: According to the surface conditions:

- decorative particleboard: impregnated paper finishes particleboard; decorative laminate veneer particle board; veneer veneer particleboard; surface coated particleboard; PVC veneer board and so on.

- Q: A simple introduction to particleboard

- the style of furniture better raw materials. Finished particleboard does not need to be dried again, can be used directly,

- Q: Make the raw material of the particleboard

- The dried shavings are then mixed with liquid gums and additives. Usually in the shavings of the surface area per square meter, sizing 8 to 12 grams

- Q: Particleboard in the production process of environmental performance

- to be stored for some time after the observation room. If no spiky smell that particleboard release of formaldehyde less, the use will not affect human health

- Q: Particleboard production process requires proper hot pressing pressure

- and then sawing sanding, inspection packaging. But after the pressure can not heat stacked, otherwise it will increase the sheet brittle.

- Q: So for the particleboard formaldehyde release of the situation how to deal with it?

- in fact, after the decoration of the room, such as Chlorophytum, Citrus grandis,

- Q: From the appearance point of view

- look at the central part of the cross-section of the size and shape of wood particles

- Q: What types of particleboard can be divided into?

- bending strength, vertical plate tensile strength (internal strength), grip nail force elasticity Modulus and modulus, etc

- Q: How to improve the particleboard market space

- In order to improve the quality of the particleboard and reduce the cost and improve the research and development capabilities

Send your message to us

E1 Melamine Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords