Hollow Chipboard for Door Core Use to replace of solid wood

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m³

- Supply Capability:

- 18000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

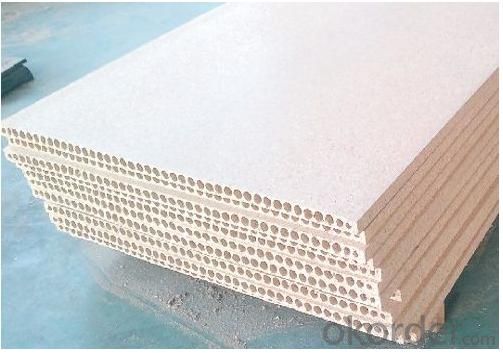

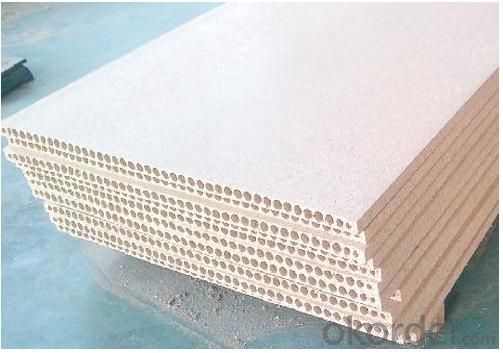

Brief Introduction: Hollow chipboard is usually used as core of Doors,and it is featured as light in weight , sound-proof anti-impact , temperature-keeping and stable in dimensions,The product reserves the virtues of wood and gets rid of its weak points such as skrinking after being wet ,and being heavy in weight,It is indeed an ideal green enwironment-friendly replacement to solid wood cores.

Pictures:

Description:

1)size:2000*125mm,2090*1180mm,2000*900mm

2)Thickness:24mm-38mm

3)Core:pine

4)Glue:E1

5)Density:350-400 kg/m³

Hollow chipboard Feafures and Advantages:

1)Envuronmental protection

2)Heat preservation

3)Sound insulation

4)Light in weight

5)Anti-impact

6)Stable in dimensions

7)Easy to processing

FAQ:

A: What's the main material of hollow chipboard?

B: Poplar

- Q: Some of advantages of particleboard

- the internal cross-scattered structure of the granular, the direction of the performance of the same basic, transverse bearing capacity is good;

- Q: Today's demand for wood-based panel products

- Beijing Olympic Games 280 billion yuan of investment, Shanghai World will be more than 250 billion yuan of direct investment,

- Q: According to the surface conditions:

- not the surface of the particleboard: sanding particleboard; not sanding particleboard.

- Q: The environmental performance of particleboard

- . It is a complicated process to detect the formaldehyde emission of particleboard.

- Q: Particleboard industry is currently looking ahead

- so the effective utilization of forest resources and papermaking pulp waste has been paid more and more attention

- Q: Particleboard production process requires proper hot pressing pressure

- Box molding method is a special press pressure, a pressure made of products for the manufacture of crates.

- Q: Particleboard by product classification

- According to the arrangement of shavings in the slab, there are two kinds of directional and random type

- Q: From the appearance point of view

- the length is generally 5-10MM length is appropriate, too long structure loose, too short anti-deformation of the poor, the so-called static bending strength is not compliance;

- Q: Production of raw materials for particleboard

- Production of particleboard raw materials, including wood or wood fiber materials, adhesives and additives, the former accounted for more than 90% of the dry weight of the plate.

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the use of raw materials: wood particleboard; bagasseboard particleboard; linseed particle board; cotton stalk particle board; bamboo particle board; cement particle board; gypsum particleboard.

Send your message to us

Hollow Chipboard for Door Core Use to replace of solid wood

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m³

- Supply Capability:

- 18000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords