Aluminum magnesium manganese system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

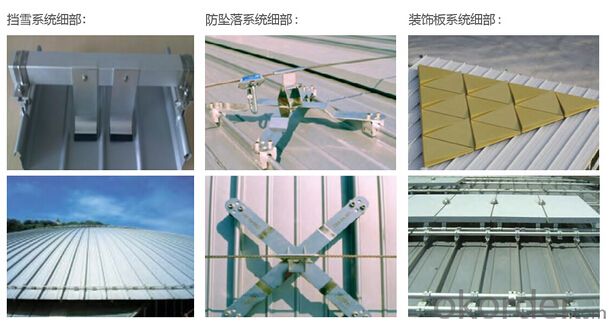

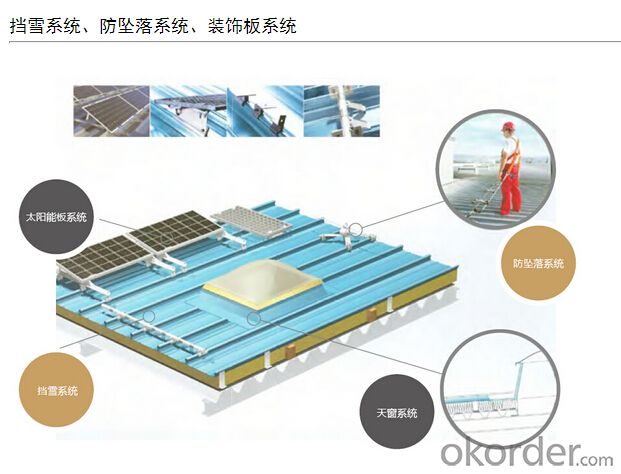

System introduction:

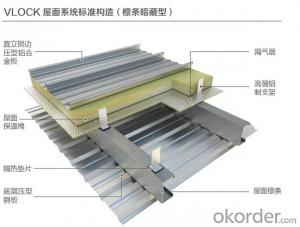

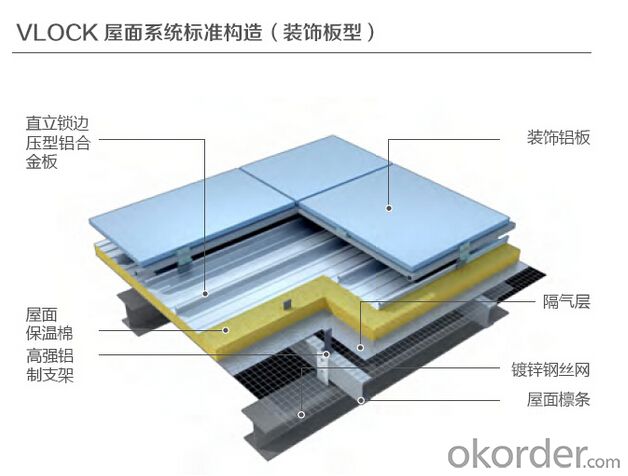

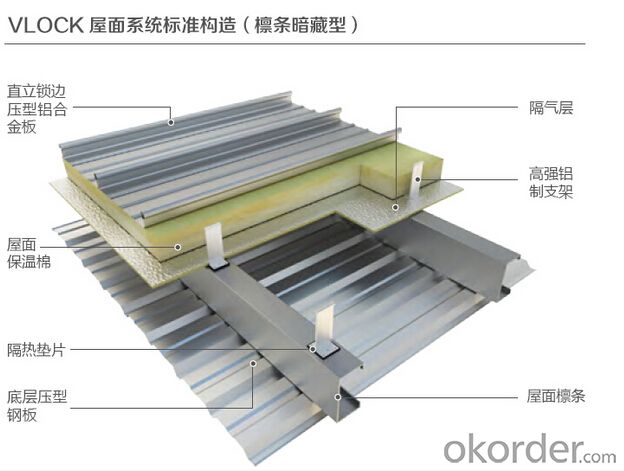

DW Al-Mg-Mn board is the alloy mixed by metallic aluminum, metallic magnesium and metallic manganese. The metallic aluminum, magnesium, manganese alloy is widely used as the material of metal roof for which the building design service life is more than 50 years as it has advantages such as moderate structure strength, weather-proof, waterlogging tolerance and easy be bent, welded and processed, etc.

Connection way:

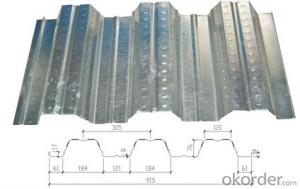

Processing of Al-Mg-Mn roof board→ measuring and setting out→ installation and calibration of support at joint → installation of purline → installation of galvanized profiled punched steel bottom board → installation of lined purline and its support → installation of gutter →aluminum alloy T support → laying of non-woven fabrics for installation → installation of acoustic wool → installation of steel wire mesh → laying of vapor barrier → installation of glass insulation cotton → installation of aluminum alloy roof board → installation of skylight → installation of sunshine board → processing of roof-crossing rods, expansion joint and other joints

Applicable project:

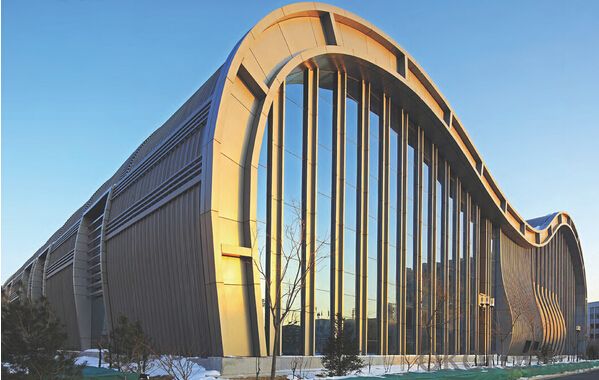

It is applicable to spherical, arc and peculiar roofs with small radian and radius, and complicated structure such as airport, stadium, conference center, business center, superior villa, convention center and industrial workshop, etc, especially applicable to large public engineering for which the roof has steel support, and also peculiar and complicated structure.

- Q: Guodong E1 grade 180 plate how to identify

- First, look at the inspection certificate. The second best veneer after use.

- Q: How about Tiantuo plate

- How to buy plate (1) whether it is environmentally friendly. According to the provisions of the indoor building materials formaldehyde emission must be less than or equal to 1.5mg / l, if more than 5mg / l is exceeded. (2) wood moisture content. When the wood moisture content is higher than the equilibrium moisture content of the environment, the wood will dry shrink, otherwise it will absorb moisture expansion. The main cause of wood cracking and deformation is that the moisture content is too high or too low. (3) Do not just cheap. Low-priced materials are usually sold and crushed and formaldehyde seriously exceeded the material, should be to the regular market to buy, it is best to buy a brand of materials. (4) the purchase of wood flooring when the tree species do not have to worry about the name, the election is the most important dealer.

- Q: Baosteel Cr2, Cr3 plate what material

- CR2 is the standard of ISO 3574, equivalent to GB03 (GB / T 5213, or EN 10130), or standard SPCD (refer to JIS 3574), or American Standard CS Type A, B (refer to ASTM A1008M-07) ; CR3, equivalent to GB04 (GB / T 5213, or EN 10130), or standard SPCE (refer to JIS 3574), or American Standard DS Type A, B (refer to ASTM A1008M-07);

- Q: Help, carpenters plate problem, is the green of Nanjing is good, or the horse's green sea good?

- Nanjing is not necessarily cheaper than the Ma On Shan This is a sure I have a customer so things are driving their own to Nanjing to buy the results of the installed down a pair of more than the price of Ma'anshan local prices more than regret ah

- Q: Hubei which brand plate more reliable?

- My home with the Cornell's plate, the price can also be, as far as I know there are Fu Han, Jin Han, but Fuhan fake more, there is a new Hong wide decorative materials, the price is relatively high, hope to you helpful

- Q: How to color the plate after carving

- First with the newspaper accounted for four weeks, leaving the word, you can spray later.

- Q: Plate and line joints at the crack causes, with morning sun water paint can improve it

- I can use the morning sun water-based wood paint, like a wooden furniture clothes, not only cleverly cover up the wood surface of the insects, knots, color and other defects, but also to highlight the beautiful texture of wood, while Play the role of protection of wood. Recommend you try, very safe

- Q: 2.2 meters high 3.5 meters deep 30, no hardware, probably the following, the budget probably how much!

- I was selling the brand name of the overall kitchen cabinet, according to the figure: If the overall 450 yuan / square: 450X7.7 = 3465 yuan, If the expansion of the calculation: 18 PCT side board 2.2X0.3X8 = 5.28 18% baffle 2.2X0.3X2 = 1.32 18 layers 3.5x0.3X6 = 6.3 5 PCT backplane 2.2X3.5X1 = 7.7 Material Amount: 18 PCT = 220 yuan / square X12.9 = 2838 yuan 5% = 135 yuan / square X7.7 = 1039.5 yuan A total of 3877.5 yuan Count all the good material,

- Q: What are the different characteristics of the plate?

- Lead plate can play the effect of radiation, the general plate does not have this ability. Understand the plate, you can go to China plate trading network to see, more types of plates.

Send your message to us

Aluminum magnesium manganese system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords