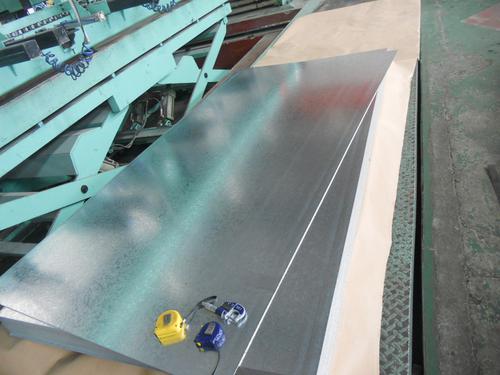

HOT-DIPPED GALVANIZED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

HOT DIPPED GALVANIZED STEEL SHEET

Steel Grade & Standard: JIS G3302 SGHC

Zinc Coating Mass: Z275

Spangle:Regular Spangle

Surface Treatment: Chromated,Unoiled,NonSkinpassed

Coil ID: ABOUT 610mm

BUNDLE Net Weight: 5MTS MAX

- Q: What is the difference between splicing and fingering of wood panels? Specifically, thank you!

- The ends of the two woods are made of teeth, and the middle is made of glue, and it is also understood that the two woods are crossed together like a finger. Splicing refers to the side of the board for gluing. Under normal circumstances, the stitching is used to access the width, the finger is used to make long. Need to stitch the wood does not require special processing, and finger of the board need to be processed at the end of the board into a tooth shape.

- Q: How to go to the market to pick a good plate?

- 1, the choice of woodworking board is particularly important. It is recommended to buy Glulam, because the laminate is solid wood, no outer skin, not easy to make fake. If you use blockboard, choose the big manufacturers, such as Langfang Jinqiu, Zhejiang Moganshan, the board was above the manufacturer's security check phone. And each board has its only serial number, like a person's identity card, can not do the fake! 2. Australian pine board is now mostly domestic, but little impact on the quality of decoration, as long as the quasi-price, it will not be too fooled. 3. The choice of the first panel depends on the color texture of the veneer, the natural veneer has a slight color difference, the artificial veneer texture is very consistent, but looks fake; followed by the bottom plate material, Liu An core floor is now very little, the panel snapped inside the folder wire. Poplar core prone to primer dialysis, a long time the surface of the paint pollution. Zamu core of the basic quality can be, and economic and durable. In fact, it is easy to say, but the layman is difficult to see inside the essence, it is best to ask a professional friend to help choose.

- Q: There are other (some of which are granite): black sands, black and white roots, purple rosewood, green diamond, blue diamond, gold flower stone, beige series, large green flowers, elegant white, jazz white, sesame white and so on. Common thickness is generally 12mm, 15mm, 18mm, 20mm, 22mm, 25mm, 30mm.

- Above the man, said very professional, very comprehensive, stone is roughly divided into granite, marble, sandstone,

- Q: Which master please teach about aluminum alloy doors and windows under the material calculation method? Flattened; push-pull can be the best example. Thank you!

- High pressure water jet cutting High-pressure water jet cutting is the use of high-pressure cylinder to the ordinary tap water pressure to 250 ~ 400MPa, and then through the hole diameter of 0.15 ~ 0.35mm gem nozzle jet to form a speed of 800 ~ 1000m / s high-speed jet, and in the water arrow Add the right amount of sand used to cut all the hard and soft materials. The advantages of water cutting are: almost no heat when cutting, the product is not thermal deformation, can guarantee product size accuracy; slit narrow and smooth cutting surface, without secondary processing, improve production efficiency; water cutting can be good To solve some high melting point, alloy, composite materials and other special materials, cutting processing. However, due to water knife and water jaw lag and incision bevel phenomenon caused by the tolerance error, for more than a certain thickness (40mm or more) or high precision parts, the use of waterjet processing and can not achieve the best results.

- Q: Millennium mill plate is good or the new millennium plate is good

- The new millennium is the king coconut group under the well-known domestic brands, fame may not thousands of years of large, it is not wasting thoughts on the minds of the mind spent on the quality of the new millennium is not a brand of goods factory specializing in the production of this brand, the other It is not to say, buy bad also buy an OEM goods you injustice injustice, anyway, we are all with the new millennium, on their own home watching the factory getting bigger and bigger, we believe that seeing is believing , Listen to the evaluation of the workers inside.

- Q: How to color the plate after carving

- When the font is colored, the first pigment (such as gold powder, silver powder, etc.), with ordinary office glue mixed mix, drop a few drops of diesel, pay attention not to be too thin, with the mud of the kind of sand sand wall can be almost , And then placed on the carved panel, with a thick plastic sheet, (the best use of silk screen with the kind of scraper), gently scraping past, the pigment will stay in the concave font, In the outside of the paint with a soft damp cloth can be wiped, and some also use advertising pigments instead of color.

- Q: Cedar Blockboard Good and Pure Wooden Plate Which is good?

- See you use the scope of what to use, but relatively do not consider the price or solid wood is good. Blockboard is a solid wood board joinery board, also known as Daixin board, the logs cut into pieces, stitching into a core, Because the main are solid wood, so many sales staff will be said to be environmentally friendly sheet, in fact, like a large core board is containing the man-made adhesive sheet. Three hydrogen ammonia plate is the MDF, with this material to do the surface of the plate are called three hydrogen ammonia plate, and the substrate is the same, and MDF, particleboard and so can be made of three hydrogen ammonia plate. Solid wood panels are durable, natural lines, mostly natural wood unique aroma, with good hygroscopicity and permeability, good for human health, does not cause environmental pollution, is the production of high-grade furniture, decoration of the high-quality housing plate. Some special materials (such as beech) solid wood board or the manufacture of buttocks, precision instruments ideal material.

- Q: What is the sheet inside that?

- Do some of the board of the board is the board, solid wood. Be a very good plate. Again is the blockboard, the middle of the board, both sides posted deck, there is not how environmentally friendly particleboard. Density board. Chen goods of the furniture or office furniture, a little more.

- Q: There is the cloakroom between those hardware is not a fixed size of what? Help you heroes

- Solid wood finger plate Refers to the board, also known as integrated board, Glulam, refers to the material, that is, after the deep processing of solid wood small pieces like "fingers" stitching the same plate, due to the use of jagged wood between the board, similar to the fingers Cross-docking, so called the board. As the wood between the cross is a combination of such a combination of the structure itself has a certain binding force, but also because there is no need to stick up and down the surface of the panel, Gu its use of the plastic extremely small. Advantages: due to the connection of solid wood panels less, with less glue, so the environmental protection coefficient relative Higher. With easy processing, cutting, drilling, sawing and forming processing. Disadvantages: solid wood finger plate easy to deformation, cracking. Good solid wood finger board quality is guaranteed but the cost is higher. 5. Multi-layer solid wood board Multi-layer solid wood board to criss-crossing the multi-layer plywood as the substrate, the surface of high-quality solid wood paste or technology wood for the fabric, the cold, hot, sanding, health and other processes made of several processes. As a result of multi-layer solid wood board is not easy to deformation characteristics and good regulation of indoor temperature and humidity of the excellent performance, surface solid wood paste leather material and natural wood texture and feel, so more selective. Therefore, much consumers of all ages. Multi-layer solid wood board with good structural stability, not easy to deformation. As the vertical and horizontal gluing, high temperature and high pressure, from the internal stress to solve the deformation of solid wood defects. In the production process using self-made high-quality environmental protection glue (corn starch), so that the product limit of formaldehyde release to meet national standards, green.

- Q: Natural granite stone plate according to its surface level of processing can be divided into three categories

- 1, fine panel (RB). It is a smooth, smooth sheet. 2, mirror sheet (PL). It is a flat surface with a glossy glossy sheet. 3, rough panel (RU). It is the surface smooth, rough, with more regular processing of the stripes of the plane board, chopped ax plate, hammer plate

Send your message to us

HOT-DIPPED GALVANIZED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords