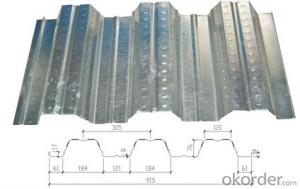

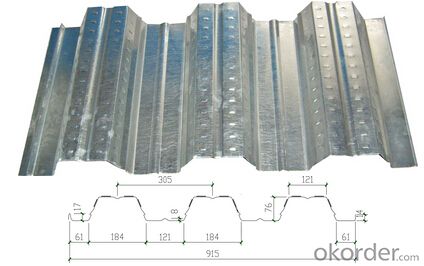

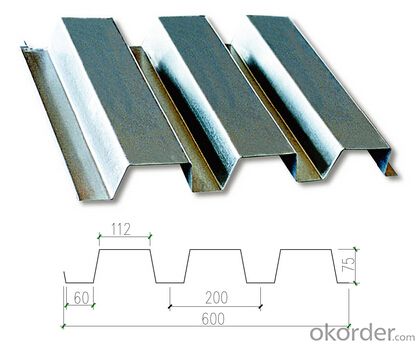

Open mouth LouCheng board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DUOWEI profiled sheet-composite slab, as permanent form in construction stage, bear construction load and concrete weight. In use stage, the profiled sheet will be used as the bottom reinforcing bar and will generate composite effect after concrete reaches the strength.

Eight advantages

There are pre-processed slots between the corrugations of the profiled steel plates, available for engineering use like electric power and communications.

The dead load of the entire structure is reduced, saving the basic cost of the lower part.

During construction, the profiled steel plate can enhance the lateral stability of the supporting steel beam.

It gives full play to the mechanical properties of two materials - steel and concrete.

It does not require formwork, getting rid of the removal and installation of formworks.

The profiled steel plate is equal to tensile main rib based on calculation, only moisture reinforcements are needed.

The profiled steel plates provide an even ceiling surface for concrete buildings.

After installation, the profiled steel plate can be used as a safety work platform for workers, tools, materials and equipments.

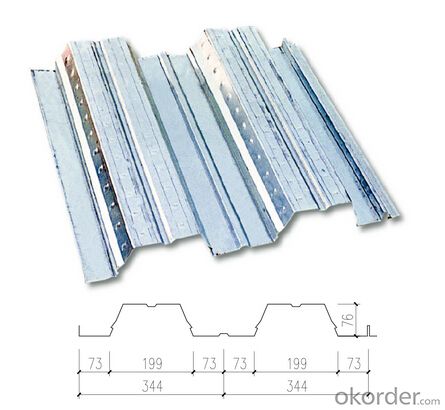

Eight major characteristics

Strong concrete bond shear resistance

With Special closed-rib design, good longitudinal shear-bearing capacity, there has never been slippage between the steel bearing plate and the concrete upon closed built-up slabs within design load limit.

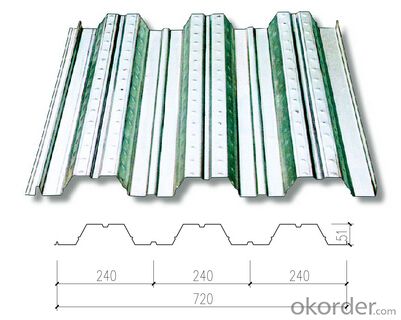

Excellent fire performance

The ribs of slab are completely encased in concrete, just like the cast-in reinforcement. Closed built-up slabs can completely replace the positive moment tensile reinforcement in the floor slabs, and an 1.5-hour refractory power can be achieved without need to brush fire-resistant coating

Superior section of built-up slabs

Closed built-up slabs have a higher effective height of the floor slab and a bigger combination stage to provide a more powerful positive moment resistance.

Board(Slab) end slot-type suspension system

For the use of ceilings, ceiling, plumbing installation, etc., no need of drilling or welding; during the building period, it can be moved, removed or reinstalled, according to the need.

Simple, rapid construction

It does not require any plug, with no leakage of mortar, available to shorten the construction cycle.

Even slab bottom appearance

The slab bottom is even, it is beautiful for the buildings not planned for the ceilings .

Effectively reduce the slab height

According to fire regulations and shatterproof requirements, the total thickness of the closed built-up slab is only 110-130 mm, 30-40 mm less than the opening profiled steel plate composite slab, thus getting a reduced self weight, reduced costs, and increased height.

Low cost

The reinforcements bearing the positive moment of the closed built-up slabs are replaced by the profiled steel plates, without need to brush fire-resistant coating, thus reducing the usage of reinforcements and cutting down the costs.

- Q: Daya solid wood particle board is good? Wardrobe and cabinet with what plate to do better?

- Daya, one of the two largest domestic man-made sheet manufacturers. Environmental protection level and the second grip nail force are more. To distinguish this plate, it is best to have the official authorization of Daya. Wardrobe: particle board is the most cost-effective preferred material, the domestic first-line brand only particle board material. If your place is very vulnerable to moisture. Can choose multi-layer solid wood board! (First-line brand foundry have to do). Not recommended woodworking board (Malacca), plate advantages: grip nail force wood is very good, shortcomings: the seam is not dense, once the joints in the joints, the wardrobe of the service life is seriously reduced. Something to buy lottery. Cabinet: the same solid wood particle board, the cabinet factory has a very good moisture treatment. Not recommended to spend money wasted, if not bad money can also choose other high-quality materials. Door: kitchen with more, try not to choose blister modeling series. Solid wood and carbon light board, and the general crystal steel doors can be! UV board acrylic best not!

- Q: Is the transparent sheet of the material the cheapest?

- PPC board with it, the price is not expensive, the most important quality is very good

- Q: Which master please teach about aluminum alloy doors and windows under the material calculation method? Flattened; push-pull can be the best example. Thank you!

- laser cutting Laser cutting is a new type of processing technology, has been widely used in metal cutting, glass cutting, sculpture and other industries. The laser is a kind of light, which is produced by the transition of atoms (molecules or ions, etc.), but it is different from ordinary light that the laser depends only on spontaneous emission only in the first short time, and the process is completely determined by laser radiation, So that the laser has a high coherence, high strength, high direction, laser cutting machine through the laser to produce laser, the mirror transmission and through the cluster mirror to the processed items, so that processed items (surface) by the strong heat and temperature A sharp increase, so that the point due to high temperature and quickly melt or vaporization, with the laser head of the trajectory to achieve the purpose of processing. The advantages of laser cutting machine are: the processing of the workpiece without mechanical pressure, so cut out the product with high precision, no secondary processing; cutting speed, easy operation, high degree of automation; can cut any complex shape of the product, Cut, the model compression process is more preferred, although the processing rate is slower than the punching, but it saves mold costs, low economic costs. But for the thickness of more than 6mm aluminum alloy sheet, the use of laser processing, cutting effect is not good, and the equipment on the use of high environmental requirements, equipment failure in the service after a long time.

- Q: Welding 1.2 plate should be used in what diameter of the electrode and the current strength?

- Welding 1.2 mm sheet, electrode diameter and current strength and other parameters are as follows: ?? ZX7 inverter DC welding machine (with the characteristics of arc stability, compared to the welding machine is more suitable for thin pieces of welding), the use of reverse (ground clamp negative pole, welding clamp positive +) polarity. ?? Electrode: 2.5 mm in diameter (the market is relatively easy to buy, theoretically diameter 2.0 electrode is difficult to buy to, and the price is much more uneconomical), welding current between 65-75 amps. ?? Welding methods and precautions: the electrode as far as possible tilt angle (to avoid the arc blowing on the formation of 1.2 plate burning), the use of rapid spot welding (arc welding), can not even arc welding, or will burn. With a cap to observe the molten pool cooled to less than the welding rod diameter re-arc welding.

- Q: The production of melamine sheet

- Melamine board Melamine board, full name is melamine impregnated film paper facing wood-based panel. Is to put the paper with different colors or textures into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing plate. In the production process, usually by the combination of several layers of paper, the number of depending on the number of purposes. General sub-surface paper, decorative paper, covered paper and the underlying paper and other components. Surface paper, is placed on the top of the decorative plate, from the role of decorative paper, so that after heating and pressing the surface of the plate highly transparent, hard surface hard wear, this paper requires good water absorption, white and clean, transparent after dipping. Decorative paper, that is, wood grain paper, is an important part of decorative panels, with a background or no background, printed on a variety of patterns of decorative paper, placed under the surface paper, mainly from the decorative effect, this layer requires paper Has good hiding power, impregnation and printing performance. Cover paper, also known as titanium white paper, generally in the manufacture of light decorative panels, placed under the decorative paper to prevent the underlying phenolic resin through to the surface, its main role is to cover the surface of the substrate color spots. Therefore, require a good coverage. The above three kinds of paper were soaked with melamine resin. The bottom of the paper, is the decorative board of the base material, the board from the mechanical properties of the role is impregnated with phenolic resin by drying, the production can be used according to the thickness of the plate or to determine a number of layers.

- Q: Why choose the lion's Provence cabinet plate?

- From the current market in terms of household products, the domestic low-grade solid wood cabinets in the use of 2 to 3 years will crack deformation, because the process does not meet the requirements, the proposed customer, you can choose Ke Liao film pressure of the old Provencal.

- Q: Does the regular FR4 sheet contain halogen?

- Very likely to contain halogen, but there is a standard, as long as no more than the minimum standards can also meet the European environmental standards.

- Q: How can quickly calculate the number of panels used in the cabinet cabinet ah? To quickly calculate whether there is a formula ah

- There is ah Let's use h to represent the height of the wardrobe. W represents the width of the wardrobe. The thickness of the electric wardrobe. Then the total area of the board used. ? This is the non-compartmentalized area, which is the total area of the outside of the wardrobe. ?? With the compartment with the corresponding compartment area on the line.

- Q: What is the quality of the board?

- The use of environmental protection factor is higher than the national standard 18mm thickness of the MDF, and the new PVC louver with a different from the general wood sheet of polymer synthetic fiber material, after 200 degrees Celsius Of the high temperature without plastic hot veneer treatment, completely free formaldehyde release. This ensures that the production of "starting line" to reduce the formaldehyde content. The quality of formaldehyde is less than or equal to 1.5mg / L, and the formaldehyde content of E1 grade (national mandatory standard) is less than or equal to 1.5mg / L

Send your message to us

Open mouth LouCheng board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords