Fire Rated Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1.100% non-asbestos

2.Bending strength 13MPa

3.Nonflammability A grade

4.Waterproof / fireproof

Calcium Silicate Factory

Product Advantages:

Calcium silicate board is made from wood lengthy fiber, concrete

and silicon sand, under the high pressure water vapor process, therefore, it performs

well in humidity durability, force resistance and fire proofing. fiber

cement board is suitable for indoor partition, ceiling and decoration.

fiber cement board presents the art of Germany know-how as a high quality

building material. It contains inorganic raw materials such as cement, silica powder

and reinforced cellulose fiber as the main materials. All boards are

autoclaved to become stable product. fiber cement board does not contain

any of asbestos fiber; however, it has strong bending strength like those with

asbestos.

fiber cement board can be applied not only for the interior use but also

for the outdoor wall system. It has low water absorption rate and high impact resistant

ability. These good advantages make it suitable for any purposes of applications.

Main Product Features:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less than 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476

10) Two point five three hours of fire rating for (6mm wall system with W-CSP concrete)

11) Radioactivity: standard (GB6566-2000)

12) Characteristic: nonflammability A grade (GB-8624-1997)

1) Heat insulation, stability, damp-proof, sound insulation, fire resistance and

light weight

2) The wall is solid and firm inside, and resistant to impact pressure

3) Painting, tiling and nailing is possible in the new system .

4) Noise reduction can be up to 46dB

5) Good efficiency

6) Working environment can keep it dry and clean for better management

7) Certificates with 2.53 hours of fire rating.

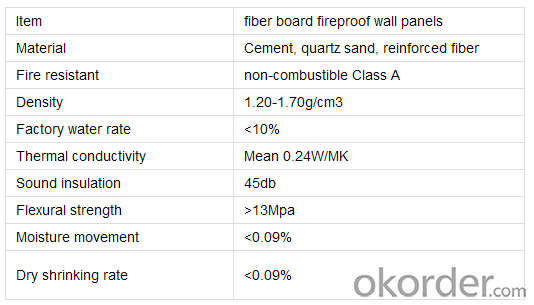

Product Specifications:

Images:

- Q: Please guide you, the decoration of the indoor use of calcium silicate board and integrated aluminum slab plate, which kind of ceiling to do good? Their advantages and disadvantages? Thank you!

- Calcium board can make a lot of shape, suitable for complex decoration, but fear of water. Suitable for business facade!

- Q: Glass magnesium board VS calcium silicate board who can be better

- Glass magnesium plate can be 30cm in diameter bending shape, will not damage its physical properties. Calcium silicate board is brittle and easy to break. Low-quality glass magnesium plate free chlorine ions, will corrode steel, metal, etc., and calcium silicate board will not. Deep processing performance: glass magnesium plate can be hot pressed three amine paper, cold pressure fire, technology, wood, etc., and silicon calcium board deep processing category is not so extensive.

- Q: What is the amount of tropicin in the calcium silicate board? Or how to define? What is the effect of the content on the quality of calcium silicate board?

- The so-called calcium silicate board is through the siliceous material (quartz sand) and calcium material (slaked lime) at high temperature and pressure (autoclave) reaction to form terbutaline, and asbestos, pulp and other fibers are skeleton effect. As for the cement, it is the strength of its own use to increase the strength of calcium silicate board, and the use of its own with a small amount of calcium, thereby reducing production costs. But the cement in the calcium silicate board should not be used, otherwise one will bring the calcium silicate board color becomes darker; Second, the most important thing is to increase the deformation coefficient of calcium silicate board, which is the calcium silicate board is The most deadly.

- Q: Calcium silicate board outside the brush coating needs grassroots?

- Now the market in Hebei, Beijing, Fujian and other miscellaneous board quality is not stable enough, the process does not pay attention to the above questions must be out. In particular, the batch of a few putty, a putty dry to do the next one, putty thickness can not be too thick, 2-3MM can, and some workers do not understand, plus buy a cheap board after the installation of wave deformation, putty approved Die thick (cracked place with shovel shovel actually have 6-8MM thick), not cracked strange. As for the paint on the normal to do like a bottom two or two bottom side, do not worry. The most important is the grassroots must be installed and installed.

- Q: Decorated with calcium silicate board to do the ceiling after the discovery of which contains asbestos ingredients. With the putty powder and paint brush brush is it harmful to the body only two of the impact of it?

- Asbestos has a high degree of fire resistance, electrical insulation and thermal insulation, is an important fire, insulation and insulation materials, after joining the anti-cracking effect, and some are added anti-cracking fiber. So that there is no impact.

- Q: Calcium silicate board to do the external wall paint how to construction

- In the calcium silicate board (plate) on the gap to be caulking. It is recommended to use the home of the heart of the card to worry about toughness to fill the joints, and then paste the seam (master understand).

- Q: Calcium silicate board above the watermark is how to cause

- Yellow whirring, and generally the reasons for the use of kraft paper fiber, dry after generally not anti-color, but I suggest you use sanded calcium silicate board, such problems will be less.

- Q: What are the extruded boards and calcium silicate board adhesives?

- Calcium silicate board on the requirements of the adhesive is relatively lower, generally used in polymer mortar mortar on it. Or else I add my Baidu HI chat, perhaps more exchanges

- Q: Silicon calcium board is not the fire board silicon calcium board is not the fire board

- As a new green building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial buildings used in ceiling ceilings and partitions, home decoration, furniture liner , Billboards, panels, warehouses, warehouses, floorboards, and tunnels.

- Q: Calcium silicate board material production methods which

- The synthesis of the dynamic process is carried out under stirring, the synthesis temperature is higher than the static process, and under pressure conditions. Dynamic process is simple, no gelation process, the product capacity is small, the performance is better, can be high temperature (1000 degrees Celsius) of the xonotlite products and ultra-light products, but need to bring the device with high pressure vessel , Equipment and process conditions require a higher energy consumption and investment are higher. At present, foreign countries use this method.

Send your message to us

Fire Rated Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords