High Purity Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

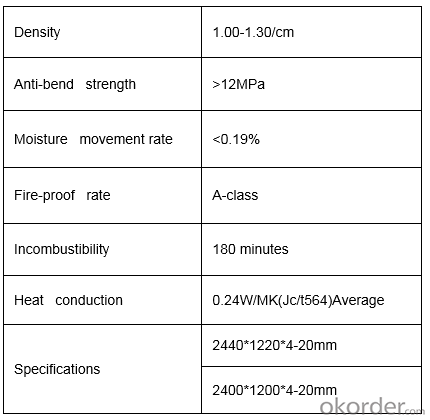

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q: Home wall with a good board or silicon calcium board

- At present, there are two kinds of calcium silicate board, one is the use of calcium silicate insulation board, there is a decoration with calcium silicate board. ? Thermal insulation with calcium silicate board, also known as microporous calcium silicate board, is a white, hard new insulation material, with a light weight, high strength, small thermal conductivity, high temperature, corrosion resistance, can cut, Features, are widely used in electric power, metallurgy, petrochemical, construction, shipbuilding, aerospace, submarines and other areas of equipment piping and wall roof insulation and fire insulation. Decorative calcium silicate board is also called fiber cement board, is a kind of energy saving, environmental protection, safety, multi-function and other properties of light plate. Calcium silicate board is a mixture of siliceous material and calcium material in a certain proportion to organic synthetic fiber, inorganic mineral fiber or cellulose fiber and other short fibers as a reinforcing material, by pulping, molding, autoclaving curing, drying , Sanding and other processes made of a new type of lightweight sheet, with light high strength, fire insulation, shrinkage deformation is small, good processing, easy to surface decoration and so on.

- Q: Calcium silicate board and magnesium silicate board which is better

- Magnesium silicate board using magnesium oxide as the main raw material, produced by the decorative materials, the advantages are: light, good toughness; drawback is: low strength, low moisture resistance, soaked after the water marinade, destruction of the wall surface The

- Q: Silicon calcium board ceiling workers how much money a square meter

- Mineral wool board: seventy / square meter, light industry: twenty / square meter. Gypsum board flat top: one hundred three / square meter, light industry: twenty - five / square meter.

- Q: Calcium silicate board seams with what kind of waterproof tape can be affixed firmly. The

- To ensure that the seams on the edge of the screw effectively locked in the same keel. Second, leave the seam problem, you must ensure that more than 5 mm left seam.Three is the seam material problem, to ensure that the joints in the material into the powder and cellulose construction If the thickness of more than 6 mm, the best hanging plastic several times hanging, and so on the layer of glue dry and then hang a layer of glue, dry after hanging on the glue and other joints with dry after the best and then linked to white plastic The last seam belt, so that in the dry environment in the north will not crack,

- Q: Calcium silicate board in the water soak for a long time will become soft or other problems, the surface can be how long the colorful paint can fade or other problems

- Calcium silicate board is not changed in the water, if the time is long, then the strength will be weakened, but if the dry will then restore the original strength

- Q: Calcium silicate board outside the brush coating needs grassroots?

- To the normal seam processing is completed, and so completely dry and then putty putty. The The In order not to finally the last crack, the construction process must be strict requirements, each process must be completely dry and then to the next process, and sometimes the workers to consider the progress, are not dry directly to do so, so that grass-roots treatment are Not normal, there will certainly be cracking, arch and other issues.

- Q: Calcium silicate board how to deal with smooth surface, that is, I would like to foil in the calcium silicate board, is to be very common to paste the bottom,

- Directly to the skin more trouble, the domestic I have not seen which business to do so, foreign Japan to do a lot, especially calcium silicate anti-static floor, are PVC or melamine paper paste. There are ways to do, you can find some floor or furniture to do a small factory, OEM can do small batch, the surface do putty layer and then sanding to the need for smoothness, and then paste the skin like, the effect is the same The

- Q: Calcium silicate board can be ground?

- Calcium silicate board light, waterproof, sound absorption, construction is simple, you can shop the ground

- Q: Calcium silicate board surface putty Why crack?

- Usually in the board and board transfer place, very prone to cracking. And then the construction of such a transfer of the time, we must do anti-cracking treatment. If cracking has occurred, it will need to be shoveled along the cracks, and then fill with a dry coating, while the bandage to play a role in anti-cracking.

- Q: Calcium silicate board bathroom can be used directly

- Can not be summed up in the home improvement is often used silicon calcium board silicon calcium board with light weight, high strength, moisture, corrosion, fire, another significant feature is that it is easy to re-processing silicon calcium board mainly composed of gypsum, there is a call Calcium silicate, calcium silicate is composed of quartz, mica, wood fiber and other ingredients.

Send your message to us

High Purity Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords