High Density Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

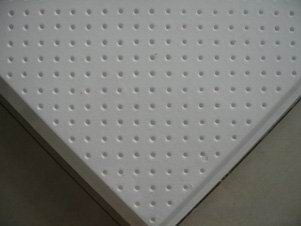

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

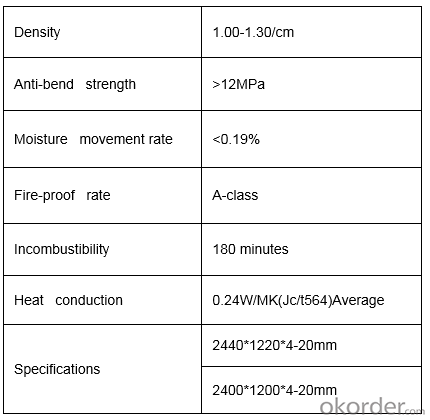

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q: The difference between calcium silicate board and plywood

- Plywood do not know the amount, but with the use of adhesive resin is certainly not environmentally friendly, there is no fully resistant to aging organic resin

- Q: Ceiling with gypsum board or calcium silicate board?

- The shape of the ceiling It is better to use gypsum board. Because it is relatively soft, hardness is not very hard It is easier to shape. Easy to operate. But the waterproof performance is not good calcium silicate board.

- Q: My home decoration ceiling, decoration company reported is easy to licensing calcium carbonate board to do smallpox, how ah, environmental protection? And the concrete board to identify it

- Calcium silicate board is now a lot of domestic asbestos, will cause lung cancer and mesothelioma, carcinogenic probability is very large, and now engage in decoration are generally funny (there are some companies do not have the ability to produce asbestos calcium silicate board With asbestos board posing), give you with asbestos calcium silicate board

- Q: Calcium silicate board and magnesium silicate board which is better

- Calcium silicate board is made of paper fiber, high purity silicon, calcium raw materials, high temperature curing made of decorative materials, with fire, moisture, insulation, insulation, noise, deformation, etc., durable for up to 30 years The

- Q: Calcium silicate board 6MM how much money one

- Calcium silicate board specifications are generally: 5mm 9MM, 12MM. 5mm in the general 20 yuan or so.

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Q: Calcium silicate with quartz powder is the number of requirements! How much silicon content?

- Should be greater than 95 (%) above the silica 325 mesh wet quartz powder is best high purity

- Q: Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- Bathroom ceiling can be changed to aluminum slab ceiling, more atmospheric, functional can do bathroom ceiling, if you like also, I just look from the individual beautiful

- Q: What is the difference between the board and the silicon board?

- Calcium silicate board contains asbestos ingredients, asbestos is a high carcinogen, harmful to humans. Ette board is fibrous silicate board, does not contain asbestos, is environmentally friendly material non-toxic harmless

- Q: What is the difference between high-density fiber cement pressure plate and calcium silicate board?

- Do the words of the wall, then I suggest that the difference between fiber and cement board to see where you use the difference

Send your message to us

High Density Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords