Calcium Silicate Board For Interior Wall Partition Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

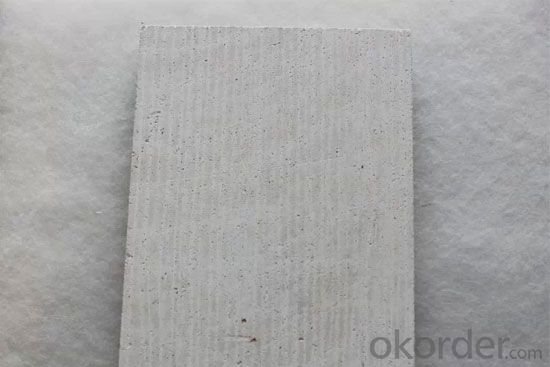

It contains inorganic raw materials such as cement, silica powder and reinforced cellulose fiber as the main materials. All ourboards are autoclaved to become stable products. It does not contain any asbestos fiber; however, it has strong bending strength like those with asbestos.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

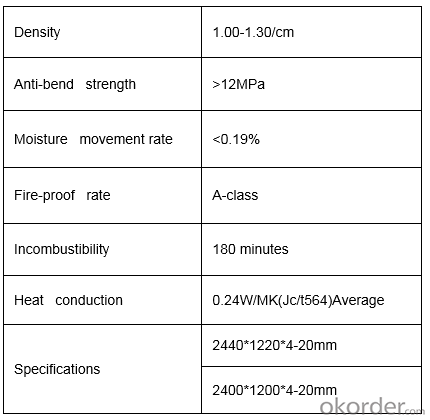

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: What is the size and classification of calcium silicate board? How do we choose the specifications for their own calcium silicate board?

- There are kilns with the use of the wall with the cut, the furnace insulation with a low temperature [650 degrees], high temperature [1050 degrees] two, the specifications are generally 600 * 300 * 25-100mm, rain off Thermal energy-saving materials Co., Ltd. mainly produces these two kinds of microporous calcium silicate board

- Q: What is the difference between calcium silicate board and gypsum board?

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates. Gypsum board (commonly used) gypsum board (commonly used), fiber gypsum board, gypsum decorative plate "interpretation") it to gypsum as the main material, adding fiber, adhesive, modifier, by mixing to suppress, dry to make. With fire, noise, heat, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction.

- Q: What is calcium silicate board?

- As a new type of building plate can be used for industrial and civil construction of the partition board and ceiling panels, the surface after the water treatment can also be used as building exterior wall and composite insulation system, especially high-rise building large format wall The Because this plate has a good fire resistance, especially for the building steel structure, bearing the cover of the fire (Table 1). Although the calcium silicate board in a variety of different applications have a corresponding alternative products, but in the application of the effect and cost there is a big difference, cost-effective. As compared with the paper gypsum board, the silicon count is slightly better than the paper gypsum board in the construction, the strength, moisture, fire, life and so on are significantly better than the paper gypsum board.

- Q: Gypsum board, Etter board, calcium silicate board, mineral wool board physical properties of what is different, the kind of hotel for the ceiling is more appropriate?

- Usually with gypsum board it. The

- Q: Calcium silicate board do background wall Why choose uv printer

- Uv printer without plate, that is, that is dry, print size depends on the printer to print the size, of course, can also block print, print material small to the box, cosmetic box, u disk, large glass, tiles, Metal plate, acrylic, etc., as long as the plane material can print, because it can print a wide range, it is also called universal printer, select the appropriate print material, set up a good printer like, not only can print 3d effect, but also Print relief effect. Print the background wall relief principle, through the computer graphics software to outline the lines to print, through the UV printer to print up. Principle is the first accumulation of white ink outline lines, and then on the color, print depth is 5mm.

- Q: What is the material of calcium silicate board

- As a new type of building plate can be used for industrial and civil construction of the partition board and ceiling panels, the surface after the water treatment can also be used as building exterior wall and composite insulation system, especially high-rise building large format wall The Because this plate has a good fire resistance, especially for the building steel structure, bearing the cover of the fire (Table 1). Although the calcium silicate board in a variety of different applications have a corresponding alternative products, but in the application of the effect and cost there is a big difference, cost-effective. As compared with the paper gypsum board, the silicon count is slightly better than the paper gypsum board in the construction, the strength, moisture, fire, life and so on are significantly better than the paper gypsum board.

- Q: Calcium silicate board commonly known as what

- Calcium silicate board as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, the more excellent performance of calcium silicate board and tide resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partitions, Home decoration, furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. It is a high-quality high-grade cement as the base material, and with natural fiber reinforced, the advanced production process molding, pressure, high temperature steaming and other special technology and made, is a good performance of the new building and industrial Plate of its products fire, moisture, noise, insect moth, durable. Is the ceiling, cut off the ideal decorative plate.

- Q: What is the difference between gypsum board and silicon calcium board?

- Calcium silicate board, the main component is calcium silicate, people to lime (all kinds of calcium materials can be used, such as cement, etc.), quartz powder (all kinds of siliceous materials can be used) as the main body to fiber as augmented Material mixed with water made of slab, and then by the autoclaved curing made of lightweight plate called calcium silicate board.

- Q: I would like to do three partitions in the room, with fiber cement board, gypsum board, fiber calcium silicate board which is better?

- You need to use the wall inside the use of professional insulation materials, or in specialized use under the special sound insulation board

- Q: Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- Environmental hazards are dangerous to people's health

Send your message to us

Calcium Silicate Board For Interior Wall Partition Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords