Calcium Silicate Board for Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

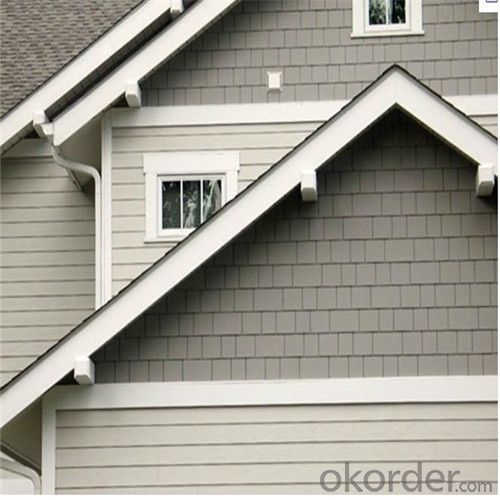

Calcium Silicate Board is mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming in Hatschek process and high pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages of high strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters

Specifications

non asbestos calcium silicate board

1)Outstanding Fire Resistance

2)Efficient Thermal Resistatant

3.5 --- 12 mm wall partition ceiling decoration calcium silicate board

Specification | Size | 2440*1220mm; |

Thickness | 4.5 to 12mm | |

Surface treatment | With or without sanded surface; bevelled | |

Custom Specifications available on request | edges available | |

Outstanding characteristics | Environmental friendly, 100% asbestos-free or 3%containing, outstanding fire resistance, high tensile and bending strength, remarkable moisture resistance, stable dimension, durable, excellent heat insulation and soundproofing, easy Installation | |

Main usage | Partitioning wall, ceiling tile | |

Other usage | Protecting wall system, movable floor, countertop, panel | |

billboard, kitchen and bathroom wall, | ||

pipeline insulation | ||

Physical property | Raw material | Tobermorite, cement, Quartz sand, fiber |

Density | 1.1-1.3 g/cm3 | |

Flexural strength | >13 Mpa; real test >15 Mpa (GB/T7019-1997) | |

Moisture content | <10%< span=""> | |

Fire rating test | Class A incombustible material (GB8624) | |

Soundproofing | 45-55 dB (GBJ75-84) | |

Thermal conductivity | ≤0.3W/MK (JC/T564) | |

Radiation | Accordance with standard (GB6566-2001) | |

Incombustibility | 4 h | |

Moisture movement | ≤0.25% (GB/T7019-1997) | |

Dry shrinking rate | <0.09%(GB/T7019-1997) | |

Application | Commercial, industrial, and apartment buildings

| |

Application:

partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Moisture:<10%< span="">

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate:<0.19% (GB/T7019-1997)

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Will the cement board rust?

- Reinforced concrete (English: Reinforced Concrete or Ferroconcrete), engineering often referred to as reinforced concrete (tong). Refers to a composite material that improves the mechanical properties of a concrete by cooperating with a composite material consisting of reinforcing steel bars, steel plates or fibers in concrete. For the most common form of stiffened concrete.

- Q: Why different buildings sound a lot worse?

- Masonry wall of the board is usually the thickness of 60 ~ 120mm, surface density is generally less than 80kg / m2, with light, easy construction and so on. The slabs can be subdivided into two categories: one is solid or porous slabs made of inorganic cementitious material and aggregates, such as (reinforced) lightweight aggregate concrete slabs, autoclaved aerated concrete slabs , Steel wire mesh ceramic concrete slab, gypsum board, etc., this type of single-layer lightweight slab wall insulation volume is usually between 32 ~ 40dB; the other is by the dense layer of material and light core material in the production Prefabricated synthetic prefabricated sandwich panels, such as concrete rock wool or polystyrene sandwich panels, fiber cement board light sandwich panels and so on. The volume of the prefabricated sandwich panel is usually between 35 and 44 dB.

- Q: Production of fiber cement board copy method has what characteristics

- Dehydration is reasonable. The net is taken from the beginning of the net, by the impact of the impact of the fur roll, in the completion of the transfer from the round to the fabric at the same time, the first layer of water can be discharged in time. The primary layer of each transmission and superposition are subject to the role of the roll roll out the water, the formation of the small material layer of water content, can be achieved before entering the vacuum dehydration process requirements. As the dehydration effect is good, resulting in a higher rate of blanking, stable production. Can be wrapped in the shape of the larger thickness of the slab. Use long fiber asbestos, can give full play to "copy the advantages."

- Q: I am in the Chicago area and it rained a few days ago.... I am also using molds and wood 4x4's

- If you are using quick crete you should be alright 24 hours later. Pnuematic tools offer less pounding on your fence which can increase the movement of your posts and therefore loose some of its tightness. Although your best bet is to look at the base of your posts and very lighty shake them and see if you concrete is still loose. Good luck.

- Q: How to choose their own materials made of steel structure compartment?

- There are many kinds of steel loft production materials, such as I-beam, H-beam, channel, square tube and so on. It is important that the owners must see is not the national standard.Now a lot of construction teams are using some non-standard products, non-standard steel has many defects, thickness, shear, tensile are not up to standard, will leave a lot of hidden dangers.

- Q: Or only where the ceramic tile floor will be installed. Should the pan just sit on the 5/8 wood subfloor?

- You can place the pan over the subfloor. You need to set the pan in mortar.

- Q: What is the quota of cement board

- Cement pressure plate does not have a special quota, and its installation process with the same gypsum board, you can use the gypsum board fixed sub-head, modify the name and price can be.

- Q: Bent cement board while installing onto floor...will it be ok?

- bent or cracked ? best that you get some cement and smooth it down or screw it to the floor if trhis is in prep for a tile floor then it will be OK .....

- Q: How does the cement pressure plate make a large brick? Specific steps and methods?

- Brick masonry molding, you must use 108 glue, paste together on the line

- Q: What is the best fixation screw in the cement board?

- A glue B glue ratio of about 1: 1 (strong glue directly), after mixing the binder should be used within 5 to 6 hours (temperature is about 20 degrees).

Send your message to us

Calcium Silicate Board for Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords