Reinforced Fiber Cement Board Usd For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

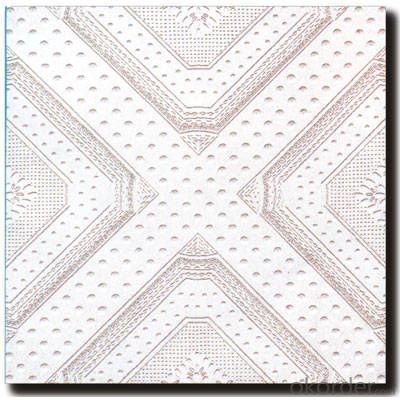

UV Siding Fiber Cement Board

1. Cheaper Than Marble, Bigger Than Ceramics

2. High Density Fiber Cement Board As Substrat

UV Siding Fiber Cement Board

1. Cheaper Than Marble, Bigger Than Ceramics

2. High Density Fiber Cement Board As Substrat

Ideal Substitute of Marble or Ceramics, Because of The Low Price, Lighter Weight, and Bigger Size of Our Product.

Product Advantages:

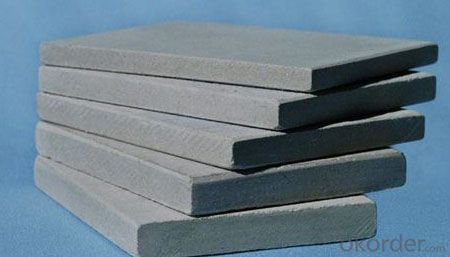

1. High density fiber cement board as substrate.

2. UV painting on the surface, Various of Patterns Includes Marble, Wooden, and Solid, Glossy and Matt for Every Pattern.

3. For Interior Wall and Ceiling Only.

4. Widely used in Hospitals, Hotels, Schools, Offices, Subways, and Laboratories.

Fireproof: "ASTM-E84 FLAME SPREAD INDEX" = 0, STANDARD <= 25

Smoke: "ASTM-E84 SMOKE DEVELOPED INDEX" =5, STANDARD <= 25

Weather Test: "ASTM-G155" = 4, STANDARD (3,5)

Main Product Features:

Standard Size: 1.22M*2.44M / 4'*8'

Thickness: 6MM

Weight: 30Kg

Surface Hardness: 3H

Product Specifications:

(Item) | (Unit) | (Result) | (Standard) |

(Density) | g/cm3 | 1.6 | 1.4<D<=1.7 |

(Weathering Test) |

| 4 | 3<=W<=5 |

(Flexural Strength) (Dry) | MPa | 19.5 | >=18 |

(Flexural Strength)(Saturated) | Mpa | 16.5 | >=14 |

(Water Absorption) | % | 19.6 | <=25 |

(Wet Expansion) | % | 0.176 | <=0.23 |

Images:

- Q: Is the fiber cement board harmful to the human body?

- Look at what material is synthesized by the general fiber is safe, including heavy metal elements of the material is not good, such as mercury tin and macromolecular materials such as high school chemistry in the synthesis of macromolecules is not conducive to permeability

- Q: Can cutting the steel cutting machine cut the cement board?

- Cutting machine: With the development of modern mechanical processing industry, the quality of cutting, precision requirements continue to improve, to improve production efficiency and reduce production costs, with high intelligent automatic cutting function requirements are also improved. The development of CNC cutting machine must meet the requirements of the development of modern mechanical processing industry. Cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water cutting and so on. Laser cutting machine for the fastest efficiency, the highest cutting accuracy, cutting thickness is generally small. Plasma cutting machine cutting speed is also very fast, cutting a certain degree of slope. Flame cutting machine for the thickness of the carbon steel material.

- Q: Seeking wire mesh clip on both sides of the foam cement mortar to do the wall technology.

- First fixed a good frame, and then fixed with a wooden keel wire mesh plus foam. If you are afraid of overweight, to switch to wood plaster gray knife.

- Q: Can you put ceramic tile over wood floors? If yes I was told that it wouldnt stay, even with cement board.?

- You have a lot of work going on in your house. I have a two story house. I have tile on the second floor and have had for five years. Placing tile on concrete is ideal , however if you have a two story that is impossible. You will be fine if you remove wood to your floor joice and replace with a sturdy plywood followed with the cement board sub deck. Use an industrial adhesive on both of your sub decks and use screws not nails. Like I said I have no cracks in mine after five years.

- Q: Wood fiber cement board | US rock cement board use

- Wood and cement board with cement and wood advantages: such as wood as light, flexible, good thermal insulation, construction convenience; such as cement-like solid, fire, moisture, mildew, anti-ants, show other plates are not unique Sex. Can be widely used in decorative interior and exterior walls, floors, ceilings, furniture, noise walls, elevated floor, to create a minimalist. Natural and full of Zen mood. This product also has the convenience of construction. Its surface is smooth, paint only once. And because the inner layer of wood particles, it is better to nail, you can use any woodworking tools.

- Q: Use the cement board to do the bathroom partition, how to do waterproof, with which waterproof material is better

- Now the house decoration bathroom waterproof is generally not membrane waterproof, and the usual way is to use waterproof paint to do waterproof. Waterproof coating asphalt-based waterproof coating basically no, the two commonly used paint is: (1) synthetic polymer polyurethane waterproof coating (corner, etc. need to add polyester cloth, glass cloth, etc.) (2) polymer modified asphalt SBS waterproof coating (need to add carcass reinforcement polyester cloth, glass cloth, etc.).

- Q: I want to put a small addition to the side of my concrete bungalow. it will be shed with lean to roof I want to construct this without having to put columns/post on the side of the house what I want to do is attach like a piece of 2x4 or 1x4 to the wall horizontally and have my rafter attached to it. the excisting concrete wall is made of 6 inch thick cinder blocksplease help

- You've already the answer/solution. A Ledger attached at the wall side, and some method of support at the outer edge of the roof.

- Q: What is the difference between a cement pressure plate and a cement board?

- Cement board is a cement as the main raw material processing and production of a building plate, is a between the gypsum board and stone, free cutting, drilling, carving of the building products, with its superior to gypsum board, wood fire , Waterproof, anti-corrosion, pest control, sound insulation and far lower than the price of stone and become the construction industry widely used in building materials. The cement board is prefabricated and also cast.

- Q: The difference between cement fiberboard and cement pressure plate

- Cement fiberboard and cement pressure plate is a product of two names, there is no difference. Plate of cementitious materials are cement, reinforcing materials are fiber (asbestos fiber and / or cellulose fiber).

- Q: How much is the square of the cement board

- Labor costs: light steel keel: 9 yuan / square, gypsum board 3 yuan / square (single) material costs: light steel keel (vertical spacing 400mm, three meters or less two feet through the heart): 20 yuan / square, 9.5 Mm thick plaster board: 7.5 yuan / square. Accessories: 3 yuan / square cost price: 53 yuan / square light steel keel is a new type of building materials

Send your message to us

Reinforced Fiber Cement Board Usd For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords