High Quality Reinforced Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 450 pc

- Supply Capability:

- 4500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cement board is non-asbestos fiber cement product opposed of Portland cement, cellulose fiber and refined sand. Using a special

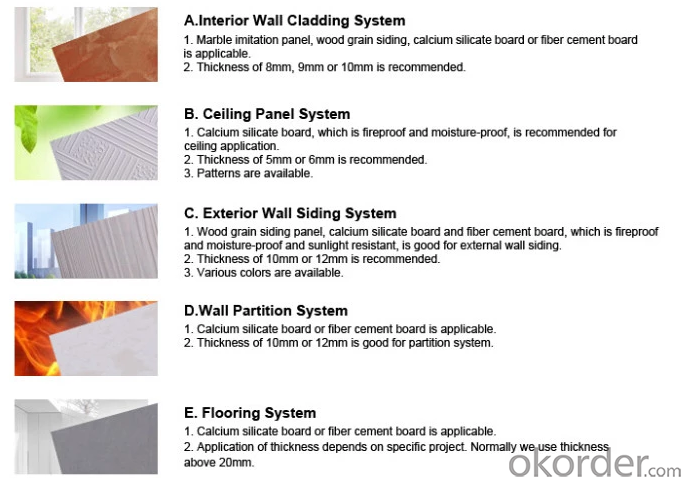

manufacturing process called autoclave; fiber cement board acquires the strength, durability of cement and easy workability of wood as well as dimensional stability. A non-combustible multi-purpose application fiber cement flat board, fiber cement board comes with various thicknesses which are suitable for various applications: ceiling, wall and floor. It can be used for both exterior and interior applications. Fiber cement board can perfectly be calibrated and then laminated or coated with other materials, such as wood veneer, painting, and steel cover.

Where can be Fiber Cement Board used for?

Fiber Cement Board is the perfect Choice for building board application such as wall cladding, wall partition and decorative wall. The types of buildings that are suitable for fiber cement board applications are residential, commercial and industrial buildings as well as schools and hospitals, especially where speedy construction, cleanliness and hygiene is of high importance.

- Q: I removed old tile from my bathroom walls as well as the old vinyl flooring. Underneath the vinyl was cement backerboard, which is good. But all around the outer edges where the wall tile used to be, is a 1 inch gap where the floor board are showing. How do I get this gap filled? Do I need to rip up the old cement backerboard and start over? Can I cut small strips of new backerboard to slip in the crevice? Is there a compound I can fill the gap with? Any help out there?

- Fill it with thin-set. There won't be any pressure applied along the wall. Fill with thin-set and wait 24 hours to dry before installing tile. Just make sure to smooth it out and it's level with rest of the backer-board floor.

- Q: our cement board was left out in a rain storm and then was installed under marble tiles. will this be an issue?

- Yes it can, but makes sure its dry before it gets closed off (tiled over)

- Q: how do you join cement board from a shower wall to drywall?

- Other than being nailed to the same stud, it is not all that necessary that they be joined together. Just figure on the tile overlapping the drywall about a half an inch to kill the crack. You can mesh tape them together however and skim them flat with each other as long as you don't skim wide into the tile board area. You could do as little as just caulk the crack with silicone too.

- Q: What are the prospects for the development of wood fiber cement board?

- VIVA wood cement board products; won the 2003 outstanding product Jin Ju Award for a modern, high-quality, economical and economical new building materials, the special surface lines can highlight the high value of texture and unique taste.

- Q: in tub and shower enclosures. What material to I use for the ceiling of the shower? Do I need to use cement board even if I am not going to tile?

- I don't think it's code to use cement backer board behind your tile, but it's smart. You can use any drywall product you want for the ceiling, but I would recommend using greenboard or a like water-resistant drywall board. Even though it shouldn't see a direct water stream on it, it will see a lot of humidity from the shower.

- Q: thinking of using Wedi Board to renovate a shower, this product is great for tile but saw a show room shower that used scratch coat cement, how hard is this to do compared to tiling?

- If you mean instead of tile, remember that unless you plan to paint it - concrete or cement is not waterproof. Think of a concrete pool - it requires periodic painting (maintenance). There are a lot of thin solid surface products out there if you do not want to look of tile. Tiling is not that hard as long as you prepare properly and take your time. There are alot of site with tiling guidelines out there - the important thing is to install/prepare the surface properly and seal the grout when you are done.

- Q: How about wood wire cement board? Is it environmentally friendly building materials?

- In the production and processing process, wood in the wood board of wood components through non-toxic chemical mineralization after the fire produced. These treated mineralized wood components combine with the Portland cement base to increase its strength and toughness, resulting in significant structural features and excellent quality of Portland cement: fire, moisture, Corrosion, pest control, and durability. The overall structure of the wood fiber board makes it resistant to impact and easy to process. Due to the close structure, high density, wood fiber reinforced concrete board sound insulation is excellent, and affordable,

- Q: is there a spray on cement moisture barrier to use under laminate flooring?

- There is no spray on, brush on, or roll on anything that will serve sufficiently as a moisture barrier. You should be painting all concrete floors with cement paint anyway but that is not enough. You need to install a membrane to act as a vapor barrier. It's a good thing anyway because it will make the floor softer to walk on if you're installing the laminate floor directly over the concrete with no sleeper boards.

- Q: How to install the solution of cement pressure plate

- Wood keel plus cement pressure plate: The most construction method, the construction of the most simple, easy. Disadvantages: wood keel in the bathroom humid environment is easy to absorb water, mold, resulting in deformation, so that the chip fried. Remedy: After installation, paste the front of the anti-root tube to do waterproof, to prevent the ground water into the riser, immersed in the wood keel.

- Q: What is the cement fiber board

- Cement fiberboard, YWN ventilation wall: 1, the annual installation (dry construction); 2, to achieve the original building color and exterior solutions; 3, to achieve the new building color and exterior solutions; 4, any geometry The structure of the external walls of the form; 5, effectively solve the building of any layers of insulation wall; 6, higher service life, keep 50 years old as new building facades.

Send your message to us

High Quality Reinforced Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 450 pc

- Supply Capability:

- 4500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords