Fiber Cement Board Panels Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

fiber cement board

-Factory price

-SGS,CE

-Non-asbestos, light weight, high density

-Waterproof, fireresistant, anti-bendingfiber cement board panels sheet for exterior cladding wall construction building material

2,Main Features of the (Cement Boards)

Fire-proof Rate: Class-A incombustible GB8624-1997

Incombustibility (min):240 minutes(GB/T9978-1999)

Density:1100~1500g/cm3

Water content ratio: ≤30%

Swelling ratio:≤0.4%

Anti-bending strength:≥16MPa

Frost Resistance: no cracking after 25 cycles of freezing and thawing(GB/T7019-1997)

Radioactivity: standard of BG6566-2001 Class-A Decoration materials.

Size & Loading Quantity of fiber cement board:

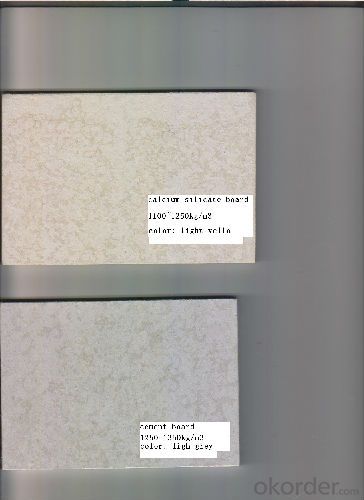

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS | Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS | Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS | Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS | Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS | Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS | Single, double surface Sanding or tapered |

| 15mm | 1200mm x 2400mm 1220mm x 2440mm | 346 PCS | Single, double surface Sanding or tapered |

| 18mm | 1200mm x 2400mm 1220mm x 2440mm | 294 PCS | Single, double surface Sanding or tapered |

| 20mm | 1200mm x 2400mm 1220mm x 2440mm | 260 PCS | Single, double surface Sanding or tapered |

5,FAQ of (Cement Boards)

Customized sizes and thickness are also produced.

Reccommend application of fiber cement board

Partition board , suspended ceilings,exterior wall cladding, paneling ,light weight grouting panel, interior dry wall decoration board, interior wall after painting and coating.

3.5-6mm : for interior ceiling

7-20mm : for drywall partition

- Q: how can i put tile in my bathroom using thin cement board.so my bathroom floor can be even with my living room floor.

- You have to consider the thresh hold-doorway. Usually it is a strip of marble. The bathroom is considered a wet area so you may not want it even with your living room floor. Blue board is most often the foundation for good tile work.

- Q: our cement board was left out in a rain storm and then was installed under marble tiles. will this be an issue?

- Yes it can, but makes sure its dry before it gets closed off (tiled over)

- Q: I am building a balcony. We were going to do tile, but may do a waterproof product instead. There is currently cement board glued (not screwed) to the torch down. Screws were not used because we don't want to have an area where water can seep in. Now I am worried about the glue failing and the cement boards lifting (same issue with tile come to think of it). Is the glue enough to hold down the cement board so I won't have problems in the future?

- If your to do ceramic tile then yes you need to screw and glue: it down. This glue isnt really to hold it down like most people think, its part of the support base for ceramic. You still must nail or screw it down in the require amount in the field ( 8 on center and seams a minimum of 4/6 apart.) If you live in a climate that gets cold enough for freezing , the I recommend you don t use a ceramic or porcelain tile ( frost proof or not) Using a cement board isn t the proper way to do an exposed balcony , even to rain. You need to treat it as a shower flooring and use a drain , liner , and s special cement to form a slight slope to the drain from all direction. It is possible ( Ive never done it yet) to properly do a cement board and water proof the top . The water proofing will have to be flashed up the sides to make a water proof flooring and still incorporate a draining system. If you have any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: i am building an outdoor BBQ island and i live in an area that snow will fall for a couple of months. i have been researching cement backer board and i cant find any recommendations on snow fall and what type of tyle is best for this application. dont want to make this investment untill i know what i am getting into. any suggestions

- I built a tile inlay on my deck for my grills. It's held up through 3 Wisconsin winters so far. I used pressure treated plywood for a base, then installed Durock over the plywood. Use Flexbond thinset for adhering the tiles. My neighbor owns a flooring store, and he set me up with an epoxy grout. You have to work it quickly to avoid a mess, but it's very durable. Hope this helps. EDIT: I would recommend using the plywood to give the Durock additional support. If you can enlarge the opening enough to wrap the Durock around the edge, you should be good. The tile and Durock should provide enough protection to keep the plywood from burning. If that will be an issue, you can screw some pressure treated 2x4's along the length of the metal frame, spaced every 16 or so, and then screw the Durock to that. This will give the top support so it won't deflect under the weight of the tile and snow, and keep the tile from popping. Good luck.

- Q: Can v board be glued directly on the wall?

- Saw board, the UV decorative panels according to the actual requirements of a block into a block.

- Q: Light steel keel cement board is what

- Light steel keel is a high-quality continuous hot-dip galvanized strip as a raw material, the cold bending process from the building with metal skeleton. It is used for decoration of non-load-bearing walls and roofs of concrete such as gypsum board, decorative gypsum board and other lightweight panels. Suitable for a variety of building roof decoration, the building inside and outside the wall and scaffolding ceiling of the basic material. According to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-keel.

- Q: What is the prc in the building?

- PRC (Pore Reduced Cement) is a high-performance cement material, it is in the process, performance, use, etc. have many unique advantages

- Q: i am wondering the durablability difference. Is one more sturdier than the other?

- Some insurance company's do not write policy's for fiber cement homes. If there is water damage, for instance, behind the siding, it is not often discovered in time to have a small claim. The claims have been huge, in some cases. Also, I have seen this type of siding damaged by wood peckers.. The bird can detect an insect or larvae behind the siding and go after them leaving behind numerous holes.. In my opinion, stone veneer is almost as good as brick.

- Q: or can i leave the seams alone? if i have to tape them what tape do i need and what compound do i need? thanks for any help!

- No need to tape the seams with a shower surround. in fact, I would just use green board instead of cement board. Cement board is mostly used for tile and the joints are sealed with a fiberglass mesh tape and tile mortar.

- Q: I'm installing a stone back splash behind my bathroom sink - 16 SF. The wall is currently painted and I want to make sure that the stone and thinset adhere properly. Should I sand the wall with 80 grit sandpaper and apply the thinset/stone or should I put 1/2 or 1/4 plywood down for better adhesion? Perhaps cement board?

- Ideal way is to do a cement board as a backer board but since its in a non wet area,( not exposed to direct water) you really don t have to.Roughing the area up is always a good idea and won t hurt a thing. I d never do a wood backer in a moist and humid environment, It can expand from moisture and break the bond. Any questions you can e amil me through my avatar and check my qualifications there. GL

Send your message to us

Fiber Cement Board Panels Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords