Customized Fiber Cement Board/ Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

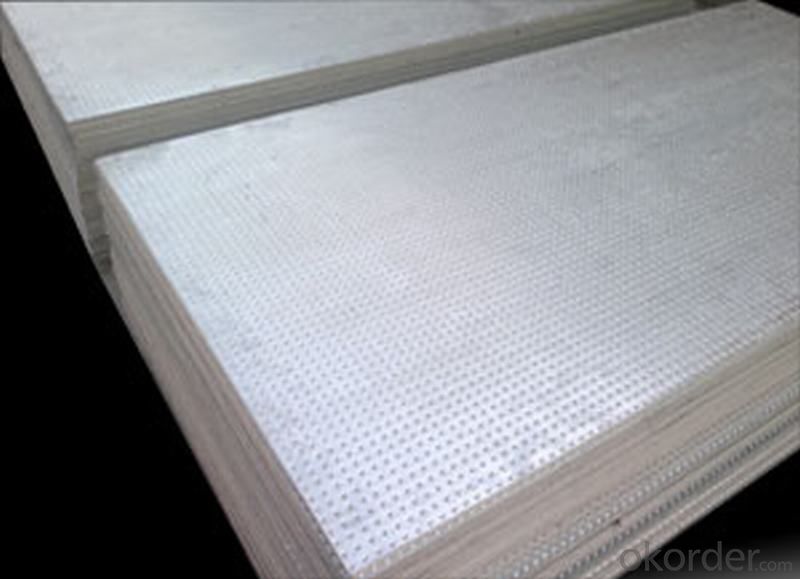

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of hightech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

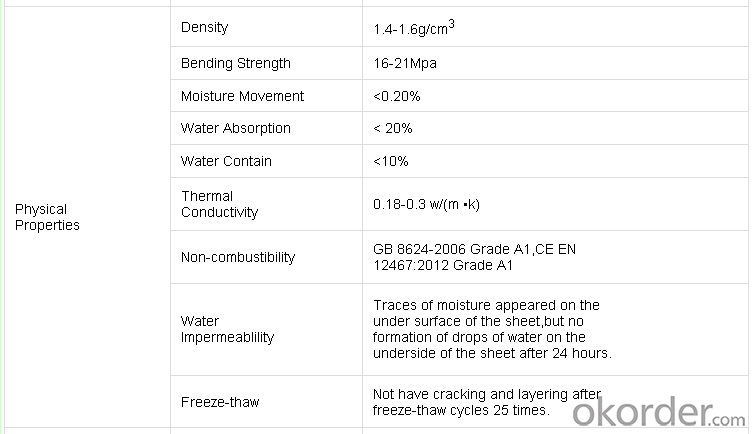

Main Product Features:

1) Incombustibility: It can not burn and give off toxic smoke.

2) Heat insulation: Low heat conductivity, good thermal insulation.

3) Waterproof: It can keep its shape without swelling and deformation after a long time.

4) Sound proof: Reduce indoor noise.

5) Environmental protection: high density reinforced fiber cement board `s special characters make more comfortable environment.

6) High Strength: High-stength and impact-resistant make it is not easy to be damaged.

7) Durability: insulation against bugs, fungus and corrosion,so reinforced fiber cement board can last for a long time.

8) Easy installation: Painting, tiling and nailing can be feasible in the new system.

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q:Installing a shower in my basement, and am framing around a fiberglass 36 square shower base. should I put it flush against the frame and then attach cement board (it will overhang) or leave room to slide cement board between base and frame? Thanks!

- I saw another answer that tells you to leave it above the flange of the base, but here is the problem with that and how I do it. If you leave it short of the base, there is now a gap however high the flange is with nothing to support the tile OR a place for the grout the sit because there is a void behind the tile. What I do is measure the thickness of the base ( usually 1/4) and then I rip a filler strip the same thickness as the flange. I nail it to the studs from the flange up to where you are going to stop the backer board or to the ceiling and then attach Hardibacker or Wonderboard to the furred out studs. Now the substrate can be installed 1/4 inch off the bottom of the base unit to avoid water wicking up and the tile has a full backing to within 1/4 of the base as well as the grout goes all the way in instead of sitting only BETWEEN the tiles as it would if you left it 1 1/2 up off the bottom sitting on the top of the flange. The only adjustment you will need to do is set the shower valve out whatever the thickness of the furring strips you add so it finishes on the tile surface to the manufacturers specs.

- Q:Replacing the cement board is not realistic, I don't know of anything that may be more flexible and not deteriorate so quickly.

- there are some colored cement repair products that contain silicone that may work good, also you can just use white silicone or caulk just squeeze it in and let it dry have a rag handy for cleanup both are flexible and last a long time.

- Q:I see pictures of peoples' dorm rooms where they have heavy pictures and bulletin boards to stick on their walls and I could never find any sticky stuff at the store that was strong enough... help!

- Is this us or uk? In uk (woolworths) you can get velcro stick on things , adhesive on both sides, really strong, Ive got my number/licence plates stuck on with it, been on 2 years, and you can pull it off when you need to. But if its just posters and stuff, then blu-tack would do it, wouldn't it?

- Q:Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- Casting is in the field of mold, bar reinforcement, watering concrete and other construction procedures to do. Compared to the prefabricated system is the overall shape, good integrity, for a pipe through, or irregular shape of the floor is still very suitable, but its processes, wet operations, the site of watering, the construction period longer The The cast-in-place slab is good and the seismic capacity is strong. Generally there will be no cracks, but thinner, if not do noise treatment, will be more noisy

- Q:I need side and rear clearance for a 15 year old wood stove. The 2x4 walls are covered with cement board and ceramic tiles. Behind that is a foundation wall.

- In WA state, with a *certified* wood stove, the clearence is anywhere from 18 to 24 inches. You can put anything non-combustable on that wall... tile, rock, brick, Z brick, or metal plating with 1 air space from backer board. You could always check with the court house to find out what your local building codes are.

- Q:Cement pressure board do wall do not work? Solid and waterproof there is no problem?

- Of course, the cement pressure plate is not the external walls of material, solid and waterproof are not meet the requirements.

- Q:Cement fiber pressure plate, fiber cement pressure plate (FC board), cement asbestos board, mineral wool decorative plate. Are these all the same? Where are they used?

- Technical indicators Transverse flexural strength: 25.4 (MPa); longitudinal flexural strength: 27.1 (MPa) Impact strength: 2.72 (KJ / m2); density: 1.7 to 1.9 (g / cm3) Impermeable: 24H bottom without water droplets appear; Frost resistance: 25 cycles of freeze-thawing without cracks, stratification. Non-flammable: in line with GB8624A class. Can provide test report, report based on: JC / T412.2-2006 The products are widely used in various types of buildings inside and outside the wall, ceiling, curtain wall lining, sound-absorbing barrier, composite wall panels and furniture, toys, pad, aluminum, electric stove, electrical, Insulation and other industrial use in the field Mineral wool decorative panels are mainly slag as the main raw material produced, mainly for indoor ceiling, sound-absorbing ceiling.

- Q:What is the best fixation screw in the cement board?

- A glue B glue ratio of about 1: 1 (strong glue directly), after mixing the binder should be used within 5 to 6 hours (temperature is about 20 degrees).

- Q:Advantages and Disadvantages of Foaming Cement Thermal Insulation Board

- According to the different production methods can be divided into physical foam insulation board and chemical foam insulation board.

- Q:I'm making designs for a house I want to build. Initially I wanted to build the house out of primarily concrete, however because of where the house is going to be going, it's not really plausible to get that amount of concrete out there to pour at once (it would be extremely difficult to get a truck out there).So my next consideration would be to build an otherwise traditional frame and instead of using drywall on the inside, I would use cement boards to panel the walls, and go for a clean, future-industrial look. I was also intending on doing something similar to the exterior.However, cement boards obviously weigh significantly more than typical drywall panels, and my main concern is whether or not a regular wood frame would be able to hold that amount of weight. So would that pose a significant issue to the extent that I should also consider using steel for the entire frame, or at least as a support system, or should wood be able to hold up just fine?

- Wood is fine. I am building a house that is using the 1/2 HardieBacker cement board panels attached to sound channel that is attached to wood studs. Works well. Building Dept approved it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Customized Fiber Cement Board/ Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords