High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

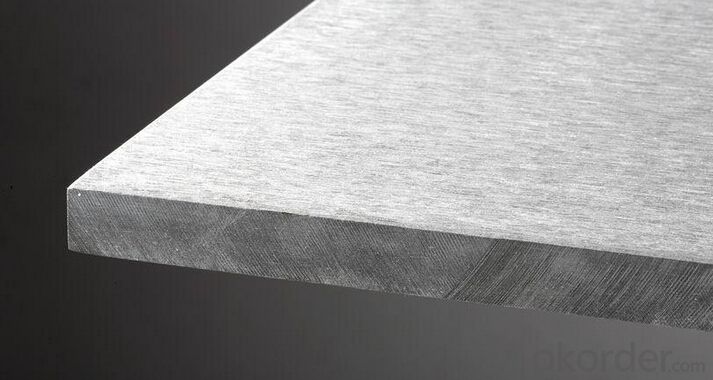

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: Glass fiber reinforced cement (GRC) board is what

- GRC is glass fiber reinforced cement products. He is composed of anti-alkali glass fiber and low alkalinity cement composed of a new type of hydraulic composite material, its main features are high strength, crack resistance, fire resistance, good toughness, not afraid of cold, easy to shape, can be made into thin, , The shape of a variety of complex building components and products, in the civil construction of agriculture, animal husbandry and fishery and environmental art and other fields have a wide range of uses. GRC Finished material is made of this composite material such as: GRC European-style components, high-strength GRC curtain wall panels, etc.

- Q: Will the cement board on the decoration be used to blow it directly?

- Can be directly putty putty. Its main material is cement, as long as you deal with the "calcium silicate board" and "calcium silicate board" between the joints. Seam to stay within a centimeter, and then fill a good tune against the plastic plaster gypsum. Plus a layer of special anti-crack bandage. This will extend its cracking time. good results.

- Q: Can the cement do not dry?

- After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board.

- Q: Can you glue glue with glue?

- As a waterproof coating use: according to the benefits of clay: water = (2.5-3.0): 1 ratio to reconcile, stirring for ten minutes, you can brush, require thick and uniform, not missing, to be on the road after curing, Brush the second or third, each time about 1.0mm thickness, (1.0-2.0) kg / m2; for some special requirements of the site, can be used glass fiber cloth or non-woven to enhance the use of "a cloth Two coated "" two cloth three Tu "process construction, the thickness of about (2.0-2.5) kg / m2.

- Q: How does that work what do they have that makes them moisture resistance?

- Hydrophobic property make it moisture free.

- Q: Bent cement board while installing onto floor...will it be ok?

- well i hope youre not using actual thinset. Thinset is for wall tile :p You want mortar. and 1/4 backerboard would have been plenty, but too late now :p even if the board cracked...assuming you screwed it down well, and mortared underneath it, it's fine. No worries.

- Q: Sorry for the double post, this is an addendum to my previous question. I am planning to re-tile the downstairs foyer. Since it's on the 1st floor of a townhouse with no basement I think there's cement slab underneath, but if I need backer board I need to purchase and make arrangements to cut (I don't own a saw yet). I'd like to take a couple tiles off to check, but how can I tell the difference between the two?

- By your question it sounds as if you intend to re-tile the floor, if so it will be concrete and you be able t tile straight over it once the other tiles have been removed and the slab made good for tiling.

- Q: i built a pair of cubed 2x4 tables,can i use cement board on top?then tile?

- With mastic cement you can stick tiles right to a wood surface providing it's flat. I used 6 floor tiles with mastic on cabinet grade plywood for our kitchen. It's lasted 17 years now. Mastic comes in plastic containers already mixed......you just trowel it on and stick your tile.

- Q: i'm going to be putting in durock in my shower? what kind of screws do i use? do they have cement board screws?

- Anodized drywall screws

- Q: A grade fireproof material cement board

- High fire resistance NK-YB01 composite foam cement board is an inorganic material, is a Class A fireproof material, which has a good fire resistance, refractoriness of 1000 ℃ or more, fully meet the external wall insulation requirements.

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords