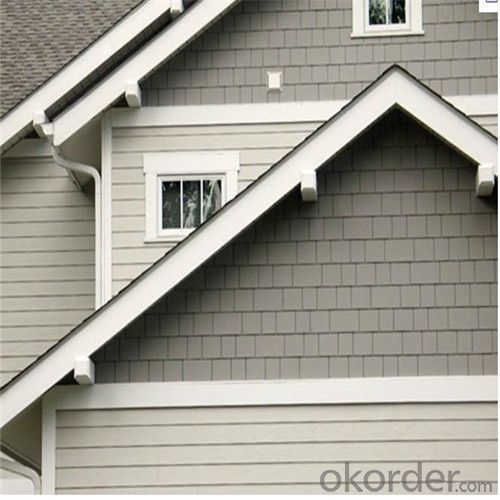

High Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard Data of the Middle Density Firber Cement Board | ||||||||

| Standard Size | 1220X2440mm/1200X2400mm | Max Width | 1250mm | Max Length | 4880mm | |||

| Thickness | 4-30mm | Density | 1.3-1.7g/cm3 | |||||

| Wet Expansion Rate | ≤0.23% | Water Penetration | ≤25% | |||||

| Forst Resistance | No Layer & no cracks after 25 cycles under freezing and thawing | |||||||

| Incombustibility | Incombustible Class A1 | Radioactivity | Decorative materials Class A | |||||

| Flexural Strength | Air dried Condition ≥18 | Water Penetration | Back side without water drop after 24 hours | |||||

| Saturated Condition≥14 | ||||||||

Application

(1)Cavity Wall for Interior Partition

1.Wet area( restroom,kitchen and basement etc.)

2.High sound insulation requirements area ( pc room,meeting room and hotel etc.)

(2) Light Concrete Grouting Wall

(3) Other Applications

1. Ceiling board

2. Perforated board

3. Aluminum lining boards and insulation barriers for high-speed train

4. Column Coverage

Production Scale and Equipment

We introduced international advanced equipment and technologies. From raw materials preparation to board forming stacking and compressing, autoclaving and destacking are all controlled by strict and efficient production craft. The whole process is full automatic, high efficient and quality stable.

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

- Q: Decorative fire board environmental protection? How to choose to buy environmentally friendly decorative fire board?

- Application of special coating process, in the sheet surface coating high-performance environmentally friendly coatings, the formation of high-quality fire environmental decorative panels. Known as green, low carbon, energy saving, environmental protection of the new decorative plate, instead of the traditional wood sheet, marble, tiles and other decorative materials, and the surface wear easy to clean, impact resistance, color stability, moisture and weather resistance.

- Q: 911 polyurethane brush in the cement board is what is the bubble

- If the performance of the paint has special requirements, when ordering the paint, to advance to the paint manufacturers sales staff instructions, if necessary, and paint engineers to communicate directly. Please do not follow the experience of other ordinary paint to treat two-component paint, do not arbitrarily change the proportion of curing agent.

- Q: I'm redoing the deck in my back yard. I've discovered the possibility of using deck tiles (wood slats, or slate, etc.) but not until after I ripped up the existing boards. There is a cement slab under my current deck. Could I just install the deck tiles on that, or would there have to be some sort of drainage system underneath? Thanks for the help!

- the best starting place for your tile project is Lowe's or the HoDepot for classes in laying tile .. they hold these sessions on Saturday [[ hope that does not interfere with your work ]] the concrete is the perfect base to lay tile .... you should

- Q: can plywood be used instead of cement backer- board for tile?

- Im not for certain but i don't think it can be used instead of cement backer board. Plywood is very preamble and the grout may soak through? I would call a Lowe's or Home Depot and ask for the flooring dept. or lumber and ask them.

- Q: Cement fiber pressure plate, fiber cement pressure plate (FC board), cement asbestos board, mineral wool decorative plate. Are these all the same? Where are they used?

- (Fiber cement pressure board, fiber reinforced cement board, fiber cement board) is a high-quality wood pulp and cement as raw material, by the pulp, forming, cutting, pressing, steaming made of a new building materials, with light, High strength, fireproof, waterproof, anti-corrosion, large format, good processing, etc., are widely used in buildings: inside and outside the wall, ceiling, curtain wall lining, steel floor, decorative wall panels, clear cement decoration and other parts The

- Q: I used a razor but it killed the blade in about two seconds. Is there a special saw for this stuff that won't make a huge mess?

- This Site Might Help You. RE: Is there an easier way of cutting Wonder Board (cement board)? I used a razor but it killed the blade in about two seconds. Is there a special saw for this stuff that won't make a huge mess?

- Q: When laying down cement backer board for a slate tile installation, I laid the board a bit too far from the wall, so I pushed it until it was flush with the wall. I think by doing this I must have shifted some of the thinset underneath, because I noticed that the board has a slight dip in it, of maybe 1/16-1/8. Is this going to be a problem, or will it be taken care of when I put thinset over it to lay the tile. This is obviously my first time laying tile.On a side note, when laying slate, is it best to use thinset or medium set, I've heard conflicting opinions.

- If you use medium set, any differences in the scale you described can be corrected fairly nicely.

- Q: how to make cement backer board for bathroom wall tiling?

- the other people answering are inexperienced. forget them. leave the drywall that is already there. install the tile with an upgraded mortar like flexbond ($30 a bag) as opposed to regular mortar at $15 a bag. the tile will be going nowhere, vent fan or no vent fan. put your tiles pretty tight together to avoid the use of alot of grout. water gets in through the grout lines which makes the tiles come loose. seal the grout with a can of grout sealer every so often so moisture doesnt get behind the tiles.

- Q: I want to cut off a lip of about 1/8 by 1/2 to accomodate the upper lip of a tub. I plan to do this with several passes of an abrasive wheel in a circular saw set to 1/8. My question is will I be able to machine the board like this or will I get a crumbling mess? the Hardiback is 1/2.

- Hardibaker peels like an onion in layers. We use it half thick often and we just cut it to size and then using a razor knife pushed in between the layers and pull them apart like opening a peanut butter sandwich. This may help you. If you run that saw on the line where you need the lip to start on the board then use your knife to split the layers and peel them down to the cut you made. This may be an easier solution then eating away the excess material a little at a time. Good Luck.

- Q: Is a vapor barrier needed behind cement board in a shower?

- on an exterior wall you will need vapour barrier

Send your message to us

High Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords