Calcium Silicate Board For Ceiling and Partition

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

The raw materials of our calcium silicate board are combined with high-purity quartz powder, high-grade cement, high-purity slaked lime, plant fiber and other mineral substances. After mixing calcium and silicate at a certain ratio, we make the raw materials into a wet sheet , keep the wet sheet under high temperature & pressure treatment by advanced technology for 1 day, then get the final product.

Standard Size: 1220*2440mm (W*L)

Thickness Range: 5mm~30mm

Packing: Pcs/Pallet

Product Advantages:

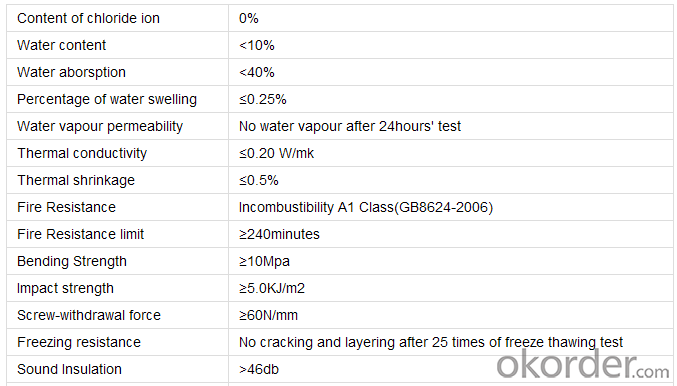

Density: 1.2~1.4g/cm3

Bending Strength: ≥10 MPA

Thermal Conductivity: ≤0.30 W/(m.K)

Moisture Content: ≤10%

Moisture Movement: ≤0.25%

Non-Combustibility: Class A

Main Product Features:

Fire Proof; High Strength & Light Weight; Easy Installation & Decoration; Fungus Proof; Resistant to Insects and Termite; Small Deformation Coefficient;

Applications:

Interior & exterior wall, ceiling, floor, kitchen and toilet wall, material of vessel and the subway projects, furniture lining, fire lining, billboards, lockers board and etc.

Product Specifications:

Images:

- Q: Calcium silicate board equipment

- Calcium silicate board equipment As the name suggests the production of fiber reinforced calcium silicate board equipment. But then buy a press to produce cement fiber pressure plate.

- Q: Calcium silicate board can be used in the roof

- Silicon calcium board, also known as gypsum composite board, which is a porous material, with good sound insulation, thermal insulation properties, in the case of indoor air humid to attract water molecules in the air, air drying, but also the release of water molecules, Appropriate to adjust the indoor dry, humidity, increase comfort.

- Q: What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Calcium silicate board is used for decoration, interior decoration. You said that this material should not be calcium silicate board.

- Q: Calcium silicate board in the water soak for a long time will become soft or other problems, the surface can be how long the colorful paint can fade or other problems

- Calcium silicate board is not changed in the water, if the time is long, then the strength will be weakened, but if the dry will then restore the original strength

- Q: Is the calcium silicate board attached directly to the wall?

- Yes, but the premise is that the wall must have a good flatness, otherwise, after the installation of the surface will be uneven.

- Q: What parts need calcium silicate board?

- Calcium silicate board is generally used for fire, waterproof requirements of the partition, ceiling, fire duct, steel fire, curtain wall liner.

- Q: 6.5 square machine room decoration ceiling how to count? Ceiling using calcium silicate board + steel keel, remove, block 8 nozzle

- Putty price is 5 yuan / square meter, the price of Putty putty is 5 yuan / square meter, latex main material is 12 yuan / square meter, rolling latex paint, 3-4 yuan / square meter. Coupled with the lamp with the circuit will be less than 400 yuan. Cleaning, garbage clean up, up to 200 yuan. Your area is so point. A 100-bedroom house decoration, the main material for the words, the renovation fee was 70,000. You only point area. It is not posted gold.

- Q: Does the apartment use silicon calcium board to make the wall right?

- Calcium silicate board shortcomings: 1, the installation of calcium silicate board, the compartment would like to change, the replacement is not easy. 2, the installation of metal keel need to use, more cumbersome works, the price is more expensive.

- Q: What are the extruded boards and calcium silicate board adhesives?

- Extrusion board on the requirements of the adhesive is relatively high, generally used to polymer mortar, two-component polymer mortar, and now some commercial resin powder instead of redispersible polymer powder Also has its advantages and disadvantages, its advantages are inexpensive, pre-bonding firm. Its disadvantages are slightly corrosive, late bonding is not very good. It is recommended to use two-component polymer bonded mortar (slightly higher cost) quality and reliable.

- Q: Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- Quartz powder, these carcinogens harmed; autoclaved alkaline drainage process, COD content is also high, and some plants are chaos row, and some plants can do zero emissions; then there is the flue gas produced by coal, the general factory Do not meet the emission requirements of it

Send your message to us

Calcium Silicate Board For Ceiling and Partition

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords