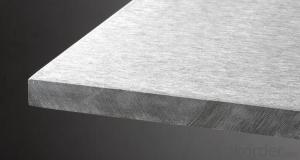

Wall partition Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

suspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding

Calcium Silicate Board is mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming in Hatschek process and high pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters

Application: partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Moisture: <10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate: <0.19% (GB/T7019-1997)

- Q: Gypsum board with calcium silicate board which is good? What are the advantages and disadvantages?

- Gypsum board advantages: light, low price, beautiful, easy to replace. Disadvantages: sound insulation performance is not easy to change the tide yellow, and the hardness is low. Silica calcium board advantages: light, moisture-proof performance, easy to change color, high hardness, good sound insulation performance. Disadvantages: replacement is not easy after installation, the installation of iron keel, the price is more expensive.

- Q: Calcium silicate board production line

- The method of copying is to flow the prepared slurry into the cage through the slurry tank, and the slurry is submerged to about 3/4 of the diameter of the reel, and the outer ring is wrapped with a certain number of internal and external networks. The upper part of the wheel set with a roll of blankets and blankets in contact with the wheel, running, the chest roller rotation to drive the blanket running, the passive roller rotation while driving the rotation of the wheel, the slurry in the role of pressure through the reel filter, Layer attached to the net outside the net, because the net is a porous and can be through the air, and the fog roll, blanket and material layer between the more dense, no air can be passed, so the material layer more easily from the reel to the wool , Thin primary layer was continuously passed on the blanket. The stirrer is used to prevent the slurry from settling, and the heavy sand debris sinks to the bottom of the tank and is periodically removed by the release plate of the floor. The material layer through the vacuum box after dehydration, winding to the forming tube, to achieve the required thickness from the molding tube after pulling off the wet blank, the next process into a variety of products.

- Q: Fiber reinforced powder quartz calcium silicate board and powder quartz calcium silicate board is what is the difference

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. It is a kind of new building and industrial sheet with excellent performance. Its products are fireproof, moisture - proof, soundproof, insect - resistant and durable, and it is an ideal decorative plate for ceiling and partition.

- Q: What parts need calcium silicate board?

- Calcium silicate board is generally used for fire, waterproof requirements of the partition, ceiling, fire duct, steel fire, curtain wall liner.

- Q: Does the apartment use silicon calcium board to make the wall right?

- With silicon calcium board to do the wall both advantages and disadvantages, the following talk about my view of it Calcium silicate board advantages: 1, good fire performance: calcium silicate board is not combustible A grade material, if a fire occurs, the plate will not search will burn, it will not produce toxic smoke. 2, excellent waterproof performance: calcium silicate board has excellent waterproof performance, in the bathroom, bathroom and other places of high humidity, can still maintain the performance of stability, will not expand or deformation. 3, high strength: calcium silicate board high strength, solid and reliable wall, easy to damage rupture. 4, heat insulation, good sound insulation: calcium silicate board has a good thermal insulation properties, but also has a good sound insulation. 6, durable, long life: calcium silicate board performance is stable, Naisuan Jian, not easy to corrosion, it will not be moisture or insects and other damage, can guarantee a long service life.

- Q: There is no material similar to calcium silicate board. Can replace the calcium silicate board. Texture is almost the same?

- The closest is the fiber cement board, calcium silicate board to do more interior decoration, and fiber cement board to do more of the external walls, you can also try the clay board, is also a beautiful board

- Q: Should go to what unit inspection, please experience the peer talk about, thank you!

- Calcium silicate board fire can reach less than 3 hours, to fiber reinforced silicate fire board can be achieved, specifically you can go to the national fixed fire detection system testing center in Tianjin. There is a Sichuan Dujiangyan National Fire Detection Center to detect. Beijing Jinyuan Hengxin Building Materials Co., Ltd. is specialized in producing this fire board.

- Q: What is the difference between inorganic silicate composite board and inorganic calcium silicate board?

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. Is a good performance of the new building and industrial sheet, its products fire, moisture, noise, insect moth, durability is better, is the ceiling, cut off the ideal decorative plate.

- Q: What is the thermal conductivity of calcium silicate board?

- Plant fiber is actually used in coated paper, which raw materials on the thermal conductivity of calcium silicate board plays a decisive role, which is easy and calcium silicate board of the parameters: Thermal conductivity W / (m.k): ≤ 0.2 Density g / m3: 0.9 Moisture content%: ≤10 Moisture ratio%: ≤0.25 Dry shrinkage%: 0.5 Impact resistance KJ / m2: ≥ 2.0 Flexural strength MPa: ≥10 Frost resistance: After 25 times freeze-thaw cycle without rupture, from the layer of the phenomenon. Watertightness: After 24H test did not appear wet marks or water droplets phenomenon. Asbestos content: 100% non-asbestos, HBC223-2005 "lightweight wall panels" Radioactive: Class A materials, production and marketing and use of unrestricted. In line with GB6566-2001 "building materials reflector nuclide limit" Non-flammable: Class A incombustible, in line with GB8624 "Building materials combustion performance grading method"

- Q: Calcium silicate board can do the shape of the ceiling? If the figure can not, figure in the shape of what is generally used to do?

- Can also be done, in fact, 6mm calcium silicate board can do this shape

Send your message to us

Wall partition Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords