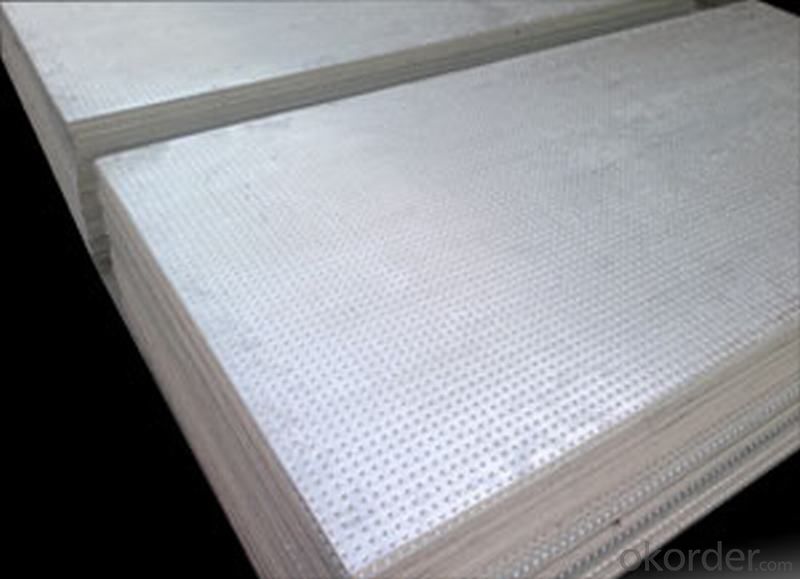

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

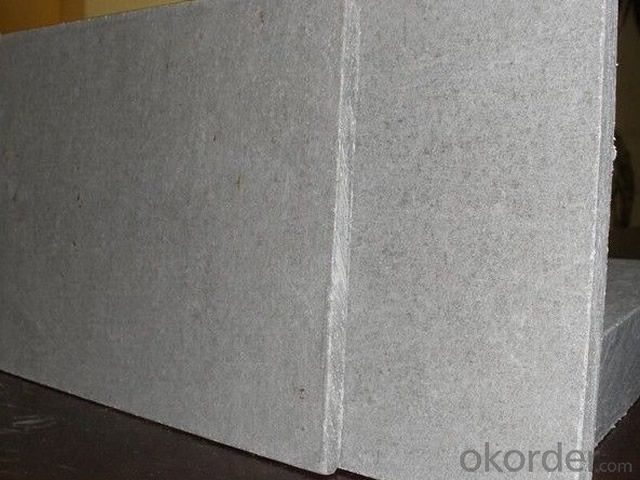

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

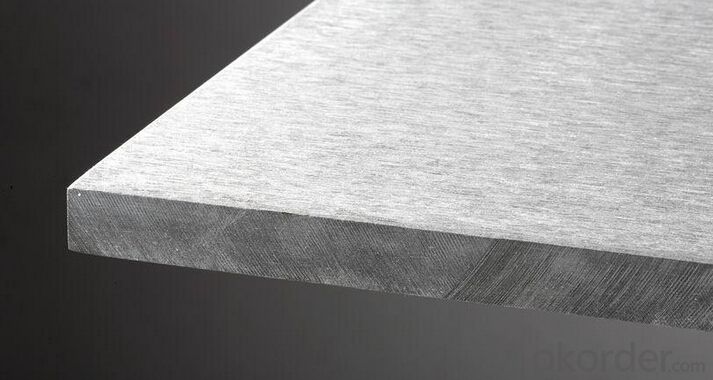

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

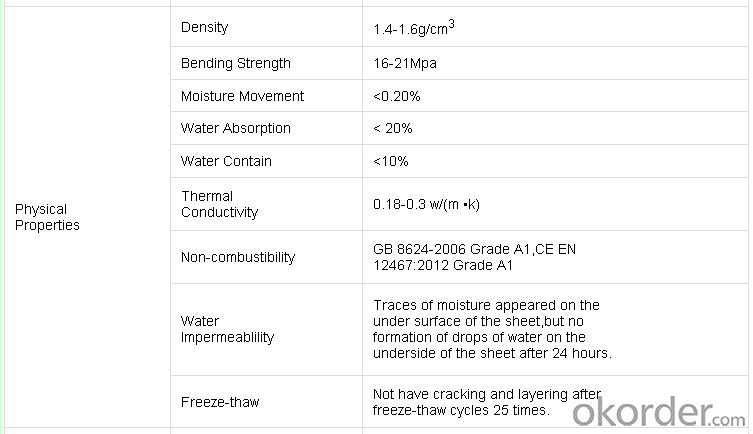

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: And the best way to attach it to a wood frame.

- Special circular saw blade sold at the big box stores. Attach with cement board screws sold at the same place.

- Q: Is it a decoration material? What's the difference?

- Clear water board is the water concrete slab, also known as decorative concrete, because of its great decorative effect named. It is a cast molding, do not make any external decoration, direct use of the natural surface effect of cast-in-place concrete as a finishes, so different from the ordinary concrete, the surface smooth, uniform color, angular, no damage and pollution, Coated with one or two layers of transparent protective agent, it is very natural, solemn. Clear water concrete is the most advanced form of concrete materials, it shows a most essential beauty, embodies the "flourishing" taste. Clear water concrete with a simple, natural calm appearance of the charm, born with heavy and elegant is a number of modern building materials can not follow and comparable. The material itself has a soft sense, hard feeling, warm feeling, cold feeling not only on the human senses and the spirit of the impact, but also to express architectural sentiment. So architects believe that this is a noble and simple, seemingly simple, in fact, more brilliant than the artistic effect.

- Q: I want to remove and replace my laminate covered counter tops, the particle board underneath is chipping bad near some edges,and there's almost no good place to put screws in to hold the dishwasher. I need plans or instructions how to build a replacement so I can use plywood and cement board to install ceramic tiles. How do I frame it for the sink and the edges?

- Actually you don't really frame a sink. You can add blocking underneath to screw to, but you really just cut the sink hole, if you are using the same sink then you will need to use the old hole as a template for the new one. If you are putting in a new sink then you will use the template on the box. You should use at least 3/4 high grade plywood and add the tile backer boards to the top. That will make it plenty think. You just cut the boards the size of the old countertop and screw then to the blocking on the wall and to the blocking in the cabinets. Blocking is additional pieces of wood that are strategiacally placed to have a larger surface to screw into and additional support. I am in commercial construction and we place the blocking inside the walls before we sheetrock, but in your case you may have to add it in other places to have enough support. Hope you have lots of luck, take your time and if you start to get frustrated ask for more help.

- Q: Would you recommend putting crazy glue in the draft boards locks, or cement?

- What works best is going in to sign up and fight for your country like a damn man :)

- Q: The floor is on a raised foundation and we were told that there are 2 options: float it on thin set or use a concrete back board. Is there any perference to one over the other? I don't want the tile to crack.

- I've never went wrong with cement backer board. Any flexibility and your grout will crack.

- Q: For bathtub enclosures what backing is required sheetrock or cementatious board?

- green board sheetrock ok. would be much better off with the cement board. install vapor barrier behind cement board.

- Q: Can someone tell me if they know or what they would think is stronger, six cement blocks stacked high or a board that is 6 feet long and 6 by 6?

- are the cement blocks stacked without mortar? are the cement blocks loaded in bending or compression? is the board loaded in bending or compression? What is the criterion of failure? cracking or breaking? Not a fair comparison with out some explanation.

- Q: We are remodeling our Bath and have put cement board around the shower which we will tile. My question is, do I continue to use cement board around the remainder of the bath or put up green board. The cement board in only 1/4 inch. Can I get greenboard that is 1/4 in. thick? I don't want a ridge between were the two meet. The tile will run half way up the wall and the other half painted in the remaining part of the bath.

- if the cement board is 1/4 inch think then add 1/4 inch backer board under the cement board to bring out the finished wall to 1/2 inch....all wall should be 1/2 or better.... walls that have 1/4 drywall are not stronge enough and will sag...

- Q: I would like to make my exterior walls more resistant against water and termites, so I would like to put cement boards instead of plywood boards before installing new vinyl siding. It costs a bit more but I think it would be worth it.

- It would cost double the amount of plywood .The nails won t hold good in just the cement board.When nailing into the cement board you may pound through the cement board if there is no wood support under it, but other than that there is no reason you couldn t. In other words I wouldn t suggest it. GL

- Q: I'm going to apply cement board over water proof sheet rock,anything special i need to do other than screw it

- Dont use green board. The first line on the spec sheet from any manufacture is do not use in tubs or showers. Use two layers of Hardi backer or Dens Shield. The Hardi is better but it is harder to cut. I have been in this business for years and I will only use one of the two listed above. G-P makes Dens Shield and they have the best warranty going. Use two layers of backer board attached with screws, tape the joints with mesh tape and durabond. Remember, grout failure is the reason most tile assemblies fail so check the grout and repair if needed, twice a year.

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords