Low Price And High Quality Partition Wall Calcium Silicate Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

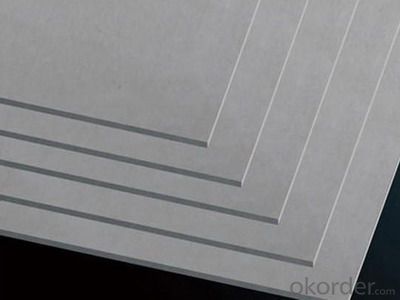

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

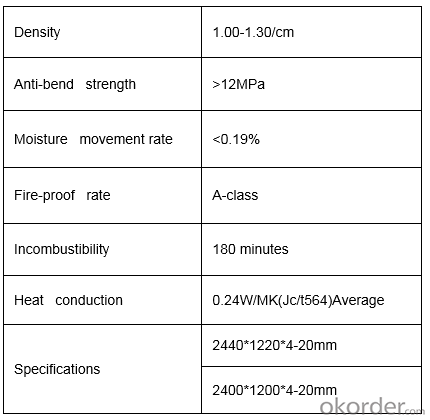

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q:What is the new environment of environmental protection wall insulation materials

- Mianshu brick, stone wood floor, calcium silicate board, light wall panels, external wall insulation board, cement foam insulation board integrated housing, composite tile and so on. These materials are now more popular building materials, the market demand.

- Q:What is the difference between high-density fiber cement pressure plate and calcium silicate board?

- In particular, the water absorption of the sheet is very important, especially asbestos-free, the density is inversely proportional to the water absorption, the higher the water absorption, the lower the density, the resistance to freezing and thawing and stability The worse, the more easy to layer, burst, so high density board for the external walls.

- Q:Calcium silicate board above the watermark is how to cause

- Calcium silicate board on the watermark is its wet embryo state, into the autoclave in the high temperature autoclaved curing process, the reaction of calcium silicate to form teromorelite crystals and water vapor in the surface condensation formation.

- Q:Calcium silicate board The so-called asbestos board is really no asbestos?

- The Etter board, which is part of the Belgian Etai Group, is a 100% non-asbestos manufacturer, which uses New Zealand imported shrub plant fibers. Is not enough to allow guests to visit the factory to watch the feeding shop when the feeding situation of the manufacturers, and the production of asbestos manufacturers can not take you to see the feeding situation.

- Q:Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Install the main keel 1> equipped with boom pheasant 2> Install the pendant on the main keel 3> Install the main keel: the main keel will be assembled hanging pendant, according to the location of the sub-line to hang the hanging pieces into the corresponding ring bolt. 4> main keel connected with the installation of connectors, pull the line to adjust the elevation, from the arch and straight. 5> around the keel with nailing Hong Ding set. Design no requirements, the nail spacing of 1000mm.

- Q:Cement fiber board calcium silicate board

- Fiber cement pressure plate and calcium silicate board in common 1, both of the raw material composition is similar, all contain silicon powder, calcium and fiber. 2, both through the process of pulping and copying. 3, both the appearance of the shape and length and width specifications are basically the same. 4, both in the use of many overlapping areas, such as inside and outside the wall and so on.

- Q:Tempered glass backdrop and calcium silicate board background wall which is better?

- Everything is good, but let me choose. I think the tempered glass wall is better.

- Q:Silicon calcium board ceiling workers how much money a square meter

- Local wages vary, the above is for reference only. More with your local workers to inquire about the price is clear.

- Q:Calcium silicate board can be ground?

- Yes, you can ceiling, floor, etc. are possible, calcium silicate board light, waterproof, sound absorption is very easy to use

- Q:Calcium silicate board why wet weather will appear scarred

- Wall junctions improperly handled: not in accordance with the requirements of the relevant nodes set construction, but in the calcium silicate board and the wall at the junction of the direct use of caulking putty full scraping, and some also use copper tape paste to strengthen, leaving no shrink space , Leading to cracking at the site.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Price And High Quality Partition Wall Calcium Silicate Board

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords