Calcium Silicate Boards Non-asbestos JN Standard Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

1. High density 130kg/m3--950kg/m3

2. High working temp. 1150C.

3.100% no asbestos .

4.Low thermal conductivity <=0.040w/m.k

2,Main Features of the (Calcium Silicate Boards)

1:Good durability, and can withstand high-temperature limit of the continuous thermal load

2:We obtained CE, KR and ISO9001

3:The highest heat resistance temperature is up to 1150 degree centigrade

4:The maximum flexural strength is up to 0.7MPa,all Technical Parameters are the best in China, it is better than other calcium silicate board in the market.

5 Our factory is corporate with the big power plant, uses the steam of the power plant to product the board, it is different from other factories to produce with the boiler. The product use the steam, the quality is better than use the boiler, so the technical parameters of our product are the best in factory. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler. So that the product from our factory is best quality and cheapest price.

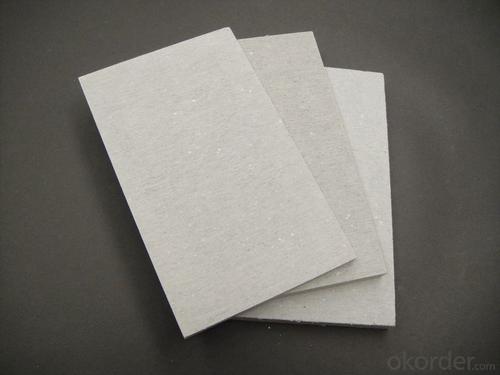

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Size & Loading Quantity of Calcium Silicate Board:

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS /

| Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS /

| Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS /

| Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS /

| Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS /

| Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS /

| Single, double surface Sanding or tapered |

Customized sizes and thickness are also produced.

5,FAQ of (Calcium Silicate Boards)

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing

Our Services:

We have own factory to produce the boards, and we are not the trading company, so we would have the directly customer service and the warranty of our boards is very good! If you need samples we can proviod first then start production as your requirement!

- Q: Fiber reinforced calcium silicate board is to do with the cut off it?

- Improve the construction speed; reduce the construction of environmental pollution have improved significantly. With the deepening of China's wall reform, silicon calcium board has been widely used as interior wall panels, wall panels and building decorative panels, ceilings, sound-absorbing ceiling panels. The product in China only 25 years of production and use of history, is both young and new building materials.

- Q: Is the calcium silicate board gypsum board?

- But the gypsum board fire and water resistance is weak, it is being replaced by calcium silicate board. In price, the price of calcium silicate board is also slightly more expensive than gypsum board, but it is worth the money.

- Q: Silicon calcium board can be used for external walls

- Calcium silicate board is less to do outside the wall panels, are generally decorated with interior walls

- Q: External wall of calcium silicate board seams posted why the grid is also cracked

- First, whether the gap between the calcium silicate board (plate) is caulked with the caulking agent, because the outdoor long-term sun and rain, the reasons for thermal expansion and contraction

- Q: Calcium silicate board outside the brush coating needs grassroots?

- To the normal seam processing is completed, and so completely dry and then putty putty. The The In order not to finally the last crack, the construction process must be strict requirements, each process must be completely dry and then to the next process, and sometimes the workers to consider the progress, are not dry directly to do so, so that grass-roots treatment are Not normal, there will certainly be cracking, arch and other issues.

- Q: Is the perforated calcium silicate wallboard used in wall decoration?

- Is used to do air conditioning room or other room soundproof wall with the plate.

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Q: Is the screw in the calcium silicate plate spin reliable?

- Decoration is so used it Harder than gypsum board, so should be no problem. Screw spacing 20-30Cm

- Q: Calcium silicate board commonly known as what

- Insulation with calcium silicate board is called microporous calcium silicate, is a white, hard new insulation material, with a light weight, high strength, thermal conductivity is small, high temperature, corrosion resistance, can cut, Widely used in electric power, metallurgy, petrochemical, construction, ship and other areas of equipment piping, wall roof insulation and fire insulation. Thickness is usually above 30mm. Density in the 200-1000kg / m3.

- Q: Calcium silicate board is not keel, you can directly nail on the wall?

- No, the same dragon skeleton. If you do not have a direct steel wall keel, directly with a wooden keel on it

Send your message to us

Calcium Silicate Boards Non-asbestos JN Standard Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords