Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

Specifications

calcium silicate board

Fireproof(Grade A)

Heat resisitance

Sound insulation

calcium silicate board

Brief Introduction:

The raw material of the calcium silicate board is the light sheet produced through

the process of pulping, forming (molding), steam-curing, surface sanding of the

siliceous material, calcium materials and reinforced fiber.

2,Main Features of the (Calcium Silicate Boards)

Main advantages:

1.Innocuity

2.Fireproof(Satisfy the standard of class A of GB8624-1997)

3.Sound insulation

4.Sawable

5.Heat resisitance

6.Impact resistance

7.Piane-able

8.Mothproof

9.Waterproof

10.Drillable

11.Long useful life period

Application:

1.Building Floor 2. Fireproof subarea partition 3. Baseboard

4. Portable partitions 5. Low wall interval 6. Glove compartment

7.Sound absorption construction 8.Indoor play crural line 9. Wall cupboard

10.Soundproof construction 11. Refractory duct 12. To counter

13. Heat insulation structure 14. Fireproof door 15. Hutch defends door plank

16. Cornice flush board 17. Arch soffit lining board 18. Advertisement Sighs etc.

Specifications:

Size: 595*595mm

603*603mm

1200*2400mm

1220*2440mm

Thickness:5,6,8,10,12,15mm

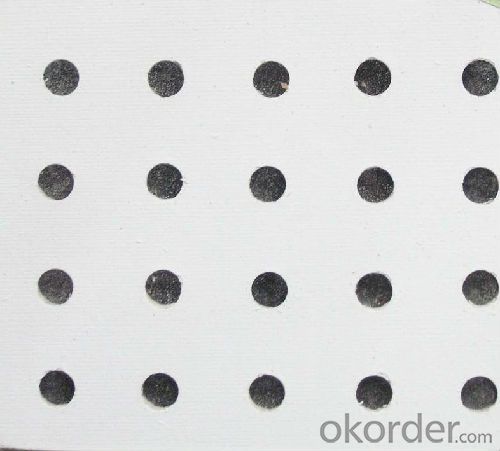

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Product parameter:

Item | Type | |||

D0.8 | D1.0 | D1.3 | ||

Density D g/cm3 | 0.75D≤0.90 | 0.90D≤1.20 | 1.20D≤1.40 | |

Flexural strength MPa≥ | e5 6 8 | 8 | 9 | 12 |

e=10 12 15 | 6 | 7 | 9 | |

e≥20 | 5 | 6 | 8 | |

Screw pullout force N/mm ≥ | 60 | 70 | 80 | |

Thermal conductivity coefficient W/(mK) ≤ | 0.25 | 0.29 | 0.30 | |

Moisture content % ≤ | 10 | |||

Wet swelling rate % ≤ | 0.25 | |||

Non-combustibility | Conform to GB 8624A | |||

5,FAQ of (Calcium Silicate Boards)

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

- Q:What is the specific difference between the silicate board and the calcium silicate board?

- Due to the repetition of the noun, it was fake, of course, some people come out to clarify: "Calcium silicate board and" calcium calcium gypsum board "has nothing to do? Isolated. Calcium silicate board is the international general high-grade ceiling wall materials, Japan, the United States, Western Europe, Southeast Asia and other regions are commonly used in the construction of sheet metal in China, to JC / T564-2000 provides its name for the calcium silicate board. Calcium silicate board was introduced to China production, although less than 15 years, Excellent performance is widely recognized by the market. "Silicon calcium gypsum board" and claiming to be "silicon calcium board", although the title of "silicon calcium", but in fact is a certain improvement of the gypsum board or even purely ordinary gypsum board, trying to confuse the calcium silicate board. So far, there is no national or building materials industry standards for this product "named".

- Q:How to identify whether calcium carbonate board contains asbestos?

- Tell you one of the most simple and most practical method, the calcium silicate board broken, lit with a lighter,

- Q:There is no material similar to calcium silicate board. Can replace the calcium silicate board. Texture is almost the same?

- What is the use of the ceiling or wall? If you do ceiling, then, or calcium silicate board cost-effective. If you do the wall, then you can use cement board instead, similar performance, but the cement board to be slightly more expensive.

- Q:Toilet with silicon calcium board ceiling, with the general opening device can not open

- Do not know how big you want to open, small can use alloy hole device

- Q:Mineral wool board, silicon calcium board, aluminum slab plate is what is the difference between the use of the place, the more detailed the better.

- Mineral wool board and silicon calcium board with mineral wool and silicon calcium powder produced, relatively heavy, aluminum plate is made of aluminum.

- Q:Decoration problem: a calcium silicate board about how many customers want me to calculate the weight. The Trouble trouble trouble.

- 1220 * 2440 * 6 Calcium silicate board normal weight at 22kg. 6 refers to the thickness of the ceiling now more than 5%, 5% is generally 18kg. Under the premise of fixed specifications, mainly depends on the bulk density. However, due to the manufacturers of different recipe technology, bulk density will be a little different. Please add points.

- Q:What are the advantages of calcium silicate board?

- The high-rise fire can be seen, because the welding so that the organic insulation layer of fire caused a major fire, if the use of calcium silicate board is absolutely impossible to such a tragedy. Comparison of all building plates, consider the above factors, the most economical is the calcium silicate board.

- Q:6.5 square machine room decoration ceiling how to count? Ceiling using calcium silicate board + steel keel, remove, block 8 nozzle

- Putty price is 5 yuan / square meter, the price of Putty putty is 5 yuan / square meter, latex main material is 12 yuan / square meter, rolling latex paint, 3-4 yuan / square meter. Coupled with the lamp with the circuit will be less than 400 yuan. Cleaning, garbage clean up, up to 200 yuan. Your area is so point. A 100-bedroom house decoration, the main material for the words, the renovation fee was 70,000. You only point area. It is not posted gold.

- Q:What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Chemical composition has long been changed, the intensity is certainly lost, do not say that fight against, there are problems with compression. Calcium silicate does not meet this requirement

- Q:High purity calcium silicate board with what cut

- Temperature 1050 degrees, very light that kind of soft This is easy to cut it, the manufacturer anyway, is cut with electric saw blade, personal processing, then worry about too light dust, hand saw knife can be.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords