Original Color Calcium Silicate Smart Board for Exterial Cladding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

Specification:

Length*: 2400*1200mm

Thickness: 4mm-30mm

2,Main Features of the (Calcium Silicate Boards)

Features:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476 standards

10) Two point five-three hours of fire rating for 6mm wall system with W-CSP concrete

11) Radioactivity: GB6566-2000 standards

12) Characteristic: nonflammability A grade (GB-8624-1997)

13) Light weight

14) The wall is solid and firm inside, resistant to impact pressure

15) Painting, tiling and nailing is possible in the new system

16) Noise reduction can be up to 46dB

17) Good efficiency

18) Working environment can keep it dry and clean for better management

19) Applications: can be used for partitions, interior walls, pipeline and conduit

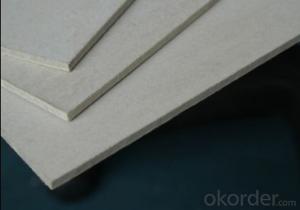

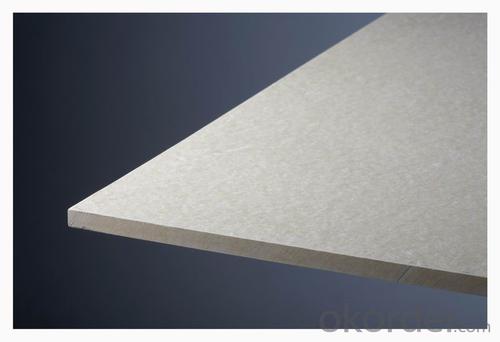

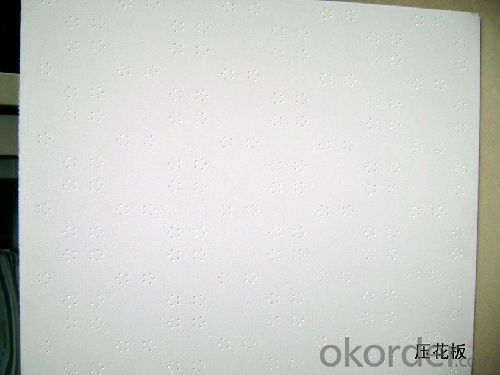

3,(Calcium Silicate Boards) Images

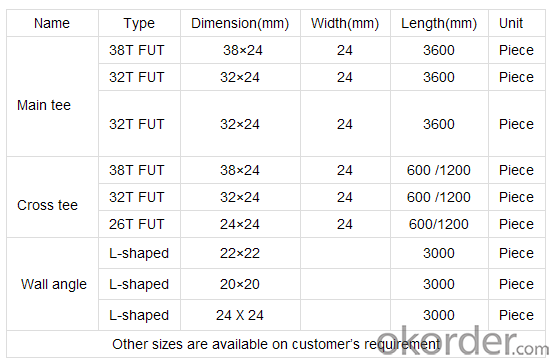

4,(Calcium Silicate Boards) Specification

5,FAQ of (Calcium Silicate Boards)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

compartments, stair space, exterior walls, ceiling boards and pillar wrapping

Packing photo of our calcium silicate board

- Q:External wall of calcium silicate board made of external wall paint

- In the putty powder surface polished and then brush the outer wall primer again, to be dry after. Brush the outer wall paint twice. carry out.

- Q:Door head decoration, outside the aluminum-plastic plate which can be used calcium silicate board?

- If the insurance can still choose the conventional blockboard (Daixinban), anyway, the door of the words of a similar, not much money, calcium carbonate than the plate is not much added:

- Q:Calcium silicate board production mode, the copy method and the quality of the comparison method, which prawn know

- Japan, the reason why Taiwan is not the use of pulp, not the level of technology is not enough, but because their main product is the density of 0.9g / cm3 below the low density board, the high density board rarely done, can not use the press, Can not make up, can not make qualified low density board. Therefore, it can be said that the applicability of the copy method is higher, and the flow slurry method is only suitable for medium and high density board, even to do low density board, its quality and copy method can not be compared. In my opinion, copy the law is the way out, after all, from the green energy-saving point of view, low-density board will be the mainstream.

- Q:Is the calcium silicate board gypsum board?

- Calcium silicate board is not gypsum board, both of them are completely different decoration materials, general decoration owners will buy these two kinds of plate to do the ceiling decoration materials, so it is very easy to get them two confused. Calcium silicate board is mainly made of siliceous materials and calcareous materials through a variety of production processes, with good fire and water, light high strength, long life, heat and sound absorption, high density and other characteristics, is the future light The main direction of the development of the partition wall. Gypsum board mainly by the construction of gypsum as raw material, the surface of a special plate for the face, after processing from the plate, but also has a light high strength, heat and sound absorption, construction and other characteristics. But the gypsum board fire and water resistance is weak, it is being replaced by calcium silicate board. In the price, the price of calcium silicate board is also slightly more expensive than the price of gypsum board, in fact, value for money. In fact, the function of calcium silicate board is more than the function of gypsum board, so want to play a larger use or choose calcium silicate board, although the price of calcium silicate board higher point.

- Q:Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- Now the basic use of aluminum ceiling plate, self-cleaning sheet can guarantee not afraid of oil, not afraid of water stains, not afraid of smell, it is important through the keel and ceiling plate between the connection, structural safety

- Q:What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Chemical composition has long been changed, the intensity is certainly lost, do not say that fight against, there are problems with compression. Calcium silicate does not meet this requirement

- Q:Who can tell me silicon calcium board, calcium silicate board, high crystal board, paperless gypsum board, glass fiberboard in the end what is the difference

- Silicon calcium board is a multi-material, generally by the natural gypsum powder, white cement, glue, glass fiber composite made. With light weight, high strength, moisture, corrosion, fire and other characteristics, and it is easy to re-processing, unlike the gypsum board as easy to reprocess the powder fragmentation.

- Q:How to build calcium silicate board mill, how much money

- Specific raw materials are plant fiber mineral fiber (asbestos) cement, limestone quartz sand, etc. according to the scale of investment of millions to tens of millions.

- Q:Silicon calcium board and mineral wool board difference between the price is the price, and the advantages and disadvantages of the material

- Of course, the price is much lower than the mineral wool board, silicon calcium board weight is much heavier than the mineral wool board weight, but the installation is not different, need light steel keel and paint keel. Mineral wool board generally ordinary price of 20 yuan, silicon calcium board price of 10 yuan or so.

- Q:Perforated calcium silicate board What is the meaning of sound absorption wall

- Calculate the wall with perforated calcium silicate board, perforated sheet with sound-absorbing effect ...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Original Color Calcium Silicate Smart Board for Exterial Cladding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches