High Quality Non Asbestos Free Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

Can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, Bestinboards are also applicable to places where high security is needed.

2,Main Features of the (Calcium Silicate Boards)

Product Features:

1.Fire-retardant

2.Thermal-insulated

3.Mildew proof

4.Moisture proof

5.Sound insulated

6.Low moisture and water absorption

7.100% asbestos free and other hazardous substances.

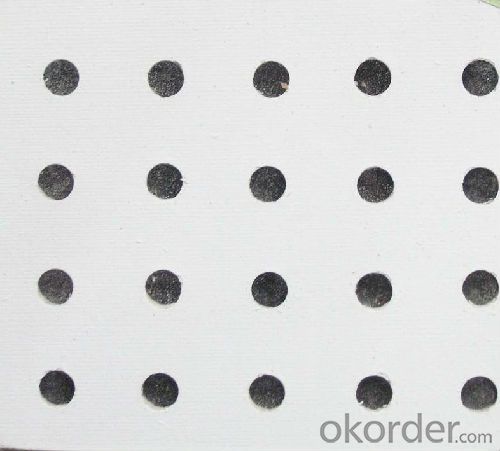

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

| Size | Standard Size | Size:1220*2440*4/6/8/9/10/12/15mm |

| Appearance | Surface | Surface:Un-Sanded/Sanded/Polished; |

| Edge | Square/Recessed/ | |

| Physical Properties | Density | 1.2-1.3g/cm3 |

| Bending Strength | Cross > 16Mpa Parallel 60-70Mpa | |

| Moisture Movement | <0.20% | |

| Water Absorption | < 0.1% | |

| Water Contain | <6%(Under EMS condition) | |

| Thermal Conductivity | 0.12-0.15 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | Interior Ceiling,Interior Patition, Bottom Liner | |

| Products Warranty | More than 20 years |

| Raw Material | Content |

| Cement | 44 % |

| Quartz | 44 % |

| Natural Fiber | 8 % |

| Suspension | 4 % |

| Composition of Finished Product | Content |

| Crystalloid of Calcium Silicate | 52% |

| Quartz | 30% |

| Calcium Carbonate | 10% |

| Cellulose | 8% |

5,FAQ of (Calcium Silicate Boards)

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing.

Trade Term

1. Payment: T/T

2 .Lead time: Samples:15 Working days;

3. Shipping freight are quoted under your requests.

4. Shipping port: Foshan,Guangzhou or Shenzhen port, Mainland China.

5. Discounts: discount based on the order quantity.

Certificate

Products are Calcium Silicate Board (Fiber Cement Board), exterior wall plate, Facade Board and lining board, etc. Our products have passed ISO certificates. CE, TUV Certificates are on progress.

- Q:What is the difference between silicon calcium board and high crystal plate?

- High crystal plate is actually improved after the calcium calcium board, more vulnerable to some moisture, not damp those deformation of the problem of color is gone. And gypsum this thing, there is breathing, you see the fracture of the tie are gypsum, breathable ah!

- Q:There is no material similar to calcium silicate board. Can replace the calcium silicate board. Texture is almost the same?

- The closest is the fiber cement board, calcium silicate board to do more interior decoration, and fiber cement board to do more of the external walls, you can also try the clay board, is also a beautiful board

- Q:What is the difference between calcium silicate board and mineral wool board?

- Mineral wool board mineral wool dust particles are easy to inhale the human body, and is a high carcinogen. Silica calcium board is the name of the fiber reinforced calcium silicate board, which is made of siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, after pulping, Support, surface sanding and other processes made of lightweight sheet. Silicon calcium board light, high strength, moisture, corrosion, easy processing, not as mineral wool board that can not be processed In terms of health and environmental protection, mineral wool board mineral wool dust particles are easy to inhale the human body, and high carcinogenic substances;

- Q:External wall of calcium silicate board seams posted why the grid is also cracked

- Ordinary caulking agent is not enough, with the toughness of the sealing agent is more appropriate, with toughness anti-cracking, it is recommended to use the home of the heart of the card to worry about toughness sealant (TB).

- Q:Please guide you, the decoration of the indoor use of calcium silicate board and integrated aluminum slab plate, which kind of ceiling to do good? Their advantages and disadvantages? Thank you!

- Calcium board can make a lot of shape, suitable for complex decoration, but fear of water. Suitable for business facade!

- Q:Should go to what unit inspection, please experience the peer talk about, thank you!

- Calcium silicate board fire can reach less than 3 hours, to fiber reinforced silicate fire board can be achieved, specifically you can go to the national fixed fire detection system testing center in Tianjin. There is a Sichuan Dujiangyan National Fire Detection Center to detect. Beijing Jinyuan Hengxin Building Materials Co., Ltd. is specialized in producing this fire board.

- Q:Calcium silicate with quartz powder is the number of requirements! How much silicon content?

- Should be greater than 95 (%) above the silica 325 mesh wet quartz powder is best high purity

- Q:Calcium silicate board sticky rock wool sandwich sandwich board what glue stick to live?

- One-component modified silane glue can try HMS60, if polyurethane glue can also be

- Q:What is the difference between calcium silicate board and gypsum board?

- Calcium silicate board as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial construction in the ceiling ceiling and partition, home decoration, furniture The lining of the billboard, the liner board of the ship, the shelf plate of the ship, the floor of the warehouse, the floor of the network, and the wall of the indoor engineering such as the tunnel.

- Q:Calcium silicate board outside the brush coating needs grassroots?

- To the normal seam processing is completed, and so completely dry and then putty putty. The The In order not to finally the last crack, the construction process must be strict requirements, each process must be completely dry and then to the next process, and sometimes the workers to consider the progress, are not dry directly to do so, so that grass-roots treatment are Not normal, there will certainly be cracking, arch and other issues.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Non Asbestos Free Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords