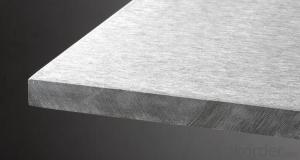

Wall partition Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium Silicate Board is mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming in Hatschek process and high pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters

Specifications

non asbestos calcium silicate board

1)Outstanding Fire Resistance

2)Efficient Thermal Resistatant

3.5 --- 12 mm wall partition ceiling decoration calcium silicate board

Specification | Size | 2440*1220mm; |

Thickness | 4.5 to 12mm | |

Surface treatment | With or without sanded surface; bevelled | |

Custom Specifications available on request | edges available | |

Outstanding characteristics | Environmental friendly, 100% asbestos-free or 3%containing, outstanding fire resistance, high tensile and bending strength, remarkable moisture resistance, stable dimension, durable, excellent heat insulation and soundproofing, easy Installation | |

Main usage | Partitioning wall, ceiling tile | |

Other usage | Protecting wall system, movable floor, countertop, panel | |

billboard, kitchen and bathroom wall, | ||

pipeline insulation | ||

Physical property | Raw material | Tobermorite, cement, Quartz sand, fiber |

Density | 1.1-1.3 g/cm3 | |

Flexural strength | >13 Mpa; real test >15 Mpa (GB/T7019-1997) | |

Moisture content | <10% | |

Fire rating test | Class A incombustible material (GB8624) | |

Soundproofing | 45-55 dB (GBJ75-84) | |

Thermal conductivity | ≤0.3W/MK (JC/T564) | |

Radiation | Accordance with standard (GB6566-2001) | |

Incombustibility | 4 h | |

Moisture movement | ≤0.25% (GB/T7019-1997) | |

Dry shrinking rate | <0.09%(GB/T7019-1997) | |

Application | Commercial, industrial, and apartment buildings | |

Application: partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Moisture: <10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate: <0.19% (GB/T7019-1997)

- Q: F-type - assembled skeleton rock wool board protective layer for the fiber reinforced calcium silicate board 05J3-1-F-type external wall insulation operation method This is what work method

- When selecting this system, you must abide by the requirements of the Atlas. ? Grass-roots walls should be solid, flat, (masonry wall of the gray seam should be flattened) protruding objects should be removed and leveling. When the rock wool board is laid, the rock wool board will be temporarily fixed in place with an anchor, and each rock wool board should have at least two anchor points, the slit shall be squeezed, ?? The width of the slabs shall not be less than 150 mm and shall have at least one anchor point, at least three anchors shall be provided on each side of the window.

- Q: Calcium silicate board can do office space wall decoration it?

- Gypsum board can Dry hanging and paving what you mean first clear

- Q: Calcium silicate board is not asbestos?

- Some, that is, "no asbestos calcium silicate board." The fiber mainly uses paper fibers instead of asbestos, but relatively speaking, the strength will be lower. If you are helpful, please add points.

- Q: My home decoration ceiling, decoration company reported is easy to licensing calcium carbonate board to do smallpox, how ah, environmental protection? And the concrete board to identify it

- Asbestos plate to see if the broken surface is a bunch of uneven dark gray flocculent fiber, this is the point of noncombustible. In addition, if it is a small plate ceiling, keel requirements are not large, if it is a large plate ceiling, pay attention to the steel keel will have a cat amount of money, may give you shoddy, this kind of thing to see a lot, the other can be considered with wood keel Ceiling, to do the anti-corrosion treatment of wood is good, mainly to prevent the filling putty cracking, because the steel keel on the vibration of the buffer is almost, or use elastic putty or AB glue filling, but also worry about bad, you can use Seam processing. Above are doing the words, basically with the housing with the birthday.

- Q: Is the calcium silicate board and the Etter plate the same material?

- Quality answer Simply said the same kind of material. The Etter board is the product of Etterit in Belgium and it should be called a fiber cement board.Endite is the inventor of the fiber cement board. Manufacturing history for more than a century.

- Q: Calcium silicate board water absorption on the performance of the plate have any effect

- Calcium silicate board if the water after the impact of the plate have a certain impact, but will not loose will not be deformed, and then back to the plate after the original strength will be restored

- Q: There is no material similar to calcium silicate board. Can replace the calcium silicate board. Texture is almost the same?

- What is the use of the ceiling or wall? If you do ceiling, then, or calcium silicate board cost-effective. If you do the wall, then you can use cement board instead, similar performance, but the cement board to be slightly more expensive.

- Q: Two layers of calcium silicate board in the middle of what kind of sound insulation board

- Calcium silicate composite rockwool sound insulation board, but now with less, mainly out of environmental protection, the use of area considerations.

- Q: How do I distinguish between calcium silicate boards and asbestos? I heard some people use cement board instead of calcium silicate board, containing asbestos ingredients!

- Asbestos fiber cement products for interior and exterior decorations and indoor ceilings, the fine asbestos fibers contained in the light, if they are inhaled, may cause refractory asbestos lung disease, which can cause various cancers and bring great (Such as Germany, France, Sweden, Singapore, etc.) has banned the production and use of all asbestos products.China has also some companies began to produce non-asbestos cement sheet.Therefore, in the decoration of the house, in the Conditions permitting, the choice of non-asbestos cement products is better.

- Q: What is the difference between perforated calcium silicate wallboard and gypsum board?

- Perforated calcium silicate wallboard as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, in the practical use of a wide range of applications. Our unit is used in Jiangsu Sanxian Architectural Acoustics System Co., Ltd. production of perforated calcium silicate wallboard.

Send your message to us

Wall partition Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords